27.3 Polyethylene

Learning Objectives

By the end of this section, you will be able to:

- Differentiate the types of polyethylene, especially LDPE and HDPE.

Polyethylene was first synthesized by the German chemist Hans von Pechmann, who prepared it by accident in 1898. Industrial production of low-density polyethylene (LDPE) began in 1939 in England. Because polyethylene was found to have very low-loss properties at very high frequency radio waves, commercial distribution in Britain was suspended on the outbreak of World War II in order to produce insulation for UHF (ultra high frequency) and SHF (super high frequency) cables of radar sets.

Polyethylene or polythene (PE) is the most common plastic. As of 2017, over 100 million tonnes of polyethylene resins are produced annually, accounting for 34% of the total plastics market. Its primary use is in packaging (plastic bags, plastic films, geomembranes, containers including bottles, etc.). Many kinds of polyethylene are known, with most having the chemical formula (C2H4)n. PE is usually a mixture of similar polymers of ethylene with various values of n.

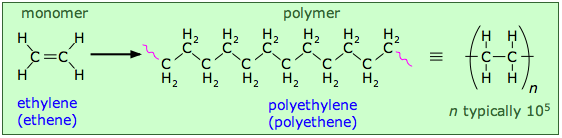

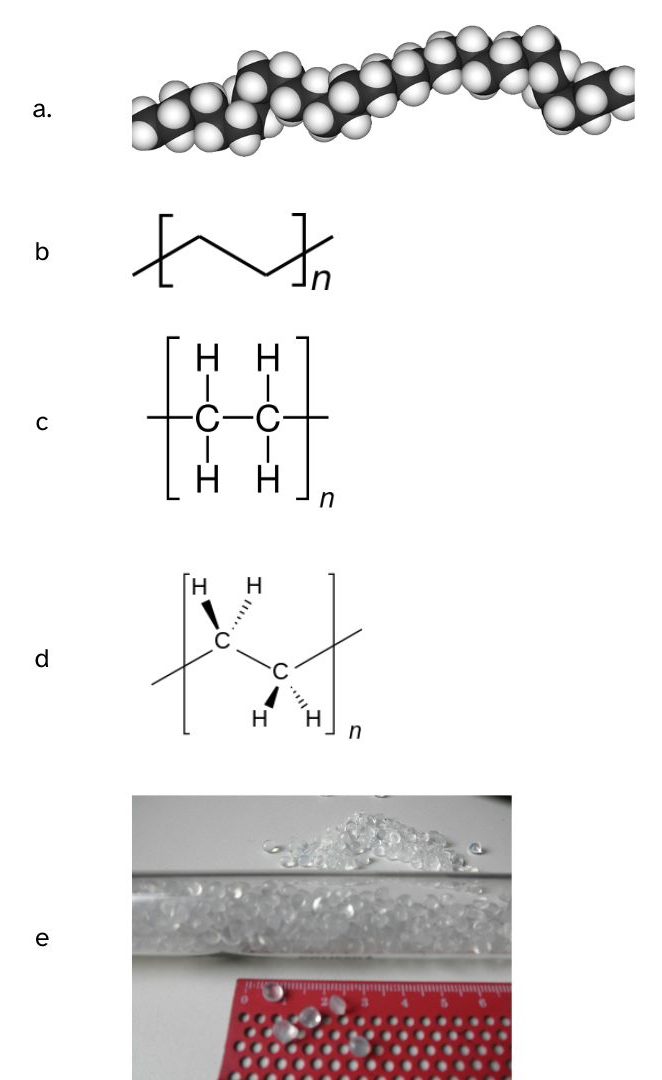

Polymers based on skeletons with only carbon are all synthetic. Let’s begin by looking at polyethylene in Figure 27.3a. It is the simplest polymer, consisting of random-length (but generally very long) chains made up of two-carbon units.

You will notice some “fuzziness” in the way that the polyethylene structures are represented above. The squiggly lines at the ends of the long structure indicate that the same pattern extends indefinitely. The more compact notation on the right shows the minimal repeating unit enclosed in brackets overprinted with a dash; this means the same thing and is the preferred way of depicting polymer structures. In Figure 27.3b., various representations of polyethylene are shown.

Types of Polyethylene

Most synthetic polymers are formed from ethylene.

The relative lengths of the chains and any branches control the properties of polyethylene.

The most important polymer grades with regard to volume are High density polyethylene (HDPE) and Low density polyethylene (LDPE). Other grades include Linear low density polyethylene (LLDPE) and Ultra high molecular weight polyethylene (UHMWPE) (Hein et al., 2014).

HDPE (High density polyethylene) is defined by a density of greater or equal to 0.941 g/cm3. HDPE has a low degree of branching. The mostly linear molecules pack together well, so intermolecular forces are stronger than in highly branched polymers. HDPE has high tensile strength. It is used in products and packaging such as milk jugs, detergent bottles, butter tubs, garbage containers, and water pipes. One-third of all toys are manufactured from HDPE. In 2007, the global HDPE consumption reached a volume of more than 30 million tons. HDPE is considered to have aligned polymer chains that support rigidity but can be brittle and crack under some circumstances (Hein et al., 2014).

Watch What Is HDPE Plastic? | High-Density Polyethylene – YouTube (2 min)

Video source: Plascon Plastics. (2021, March 18). What Is HDPE Plastic? | High-Density Polyethylene – YouTube [Video]. YouTube.

LDPE (Low density polyethylene) is defined by a density range of 0.910–0.940 g/cm3. LDPE has a high degree of short- and long-chain branching, which means that the chains do not pack into the crystal structure as well. It has, therefore, less strong intermolecular forces as the instantaneous-dipole induced-dipole attraction is less. This results in a lower tensile strength and increased ductility. The high degree of branching with long chains gives molten LDPE unique and desirable flow properties. LDPE is used for both rigid containers and plastic film applications such as plastic bags and film wrap. In 2013, the global LDPE market had a volume of almost US$33 billion. LDPE is considered to have randomly packed polymer chains that support toughness and can stretch (Hein et al., 2014).

Watch What Is LDPE Plastic? | Does Low-Density Polyethylene Really Get Recycled? – YouTube (2 min)

Video source: Plascon Plastics. (2021, June 26). What Is LDPE Plastic? | Does Low-Density Polyethylene Really Get Recycled? – YouTube [Video]. YouTube.

LLDPE (Linear low density polyethylene) is defined by a density range of 0.915–0.925 g/cm3. LLDPE is a substantially linear polymer with significant numbers of short branches. LLDPE has higher tensile strength than LDPE, and it exhibits higher impact and puncture resistance than LDPE. Lower thickness (gauge) films can be blown, compared with LDPE, with better environmental stress-cracking resistance, but is not as easy to process. LLDPE is used in packaging, particularly film for bags and sheets. Lower thickness may be used compared to LDPE. It is used for cable coverings, toys, lids, buckets, containers, and pipe. While other applications are available, LLDPE is used predominantly in film applications due to its toughness, flexibility, and relative transparency. Product examples range from agricultural films, Saran wrap, and bubble wrap, to multilayer and composite films. In 2013, the world LLDPE market reached a volume of US$40 billion.

UHMWPE (Ultra high molecular weight polyethylene) has extra-long chains of polyethylene resulting in a stiff but less brittle plastic. (Hein et al., 2014)

Watch LDPE vs. HDPE: Similarities and Difference – YouTube (2 min)

Video source: OMICO Plastics. (2020, February 14). LDPE vs. HDPE: Similarities and Difference – YouTube [Video]. YouTube.

Polyethylene Production

Watch Polythene production – YouTube (4 mins)

Video source: Royal Society of Chemistry. (2012, November 12). Polythene production – YouTube [Video]. YouTube.

Attribution & References

Except where otherwise noted, this page has been adapted by Samantha Sullivan Sauer from:

References cited in text:

Hein, M., Pattison, S., Arena, S., & Best, L. R. (2014). Introduction to General, Organic, and Biochemistry (11th ed.). Wiley.

The most common plastic formed from ethene (ethylene) monomer. Also called polyethene.

HDPE (High density polyethylene) is defined by a density of greater or equal to 0.941 g/cm3.

LDPE (Low density polyethylene) is defined by a density range of 0.910–0.940 g/cm3.

LLDPE (Linear low density polyethylene) is defined by a density range of 0.915–0.925 g/cm3. LLDPE is a substantially linear polymer with significant numbers of short branches.