4.5 Surface Imperfections

When I close my laptop, I see the matte surface of my laptop lid. I can also see several little scrapes in different places that mar the surface. When I look at the glossy black door of our kitchen microwave, I see clouds of fingerprints and am tempted to clean it right away (which I often do). These are surface imperfections that have come about during everyday use. Should the designers have chosen more appropriate materials? Could they have chosen surface materials that would be 100% resistant to the wear and tear of being used? Most likely they had to make compromises, or at least, the best decisions possible given a set of parameters such as strength, cost, and context of use.

Imperfections go against the principle of mass production, a process fundamental to industrial design, where products with imperfections are weeded out of the manufacturing line and rejected or sold as second rate.

Surface imperfections on different product surfaces: A fridge, a cell phone, a boot

However, professor Owain Pedgley and his research team believe the aesthetics of imperfection plays a key role in addressing urgent cultural and environmental issues (Pedgley et al, 2018, Pedgley, 2014). What do they mean by the aesthetics of imperfection? We have learned that the idea of aesthetics is related to an emotional response to a product based on social and cultural ideas. For example, we repair the scratches on our cars to maintain their resale value and to reflect our responsible behaviour. We also repair and paint garage doors as we expect them to have a consistent, surface appearance (which is not so easy when someone backs into one!) to reflect not only our responsible behaviour but also our judgment of a pleasing appearance.

Pedgley and his team say that surface imperfections can originate in four different ways:

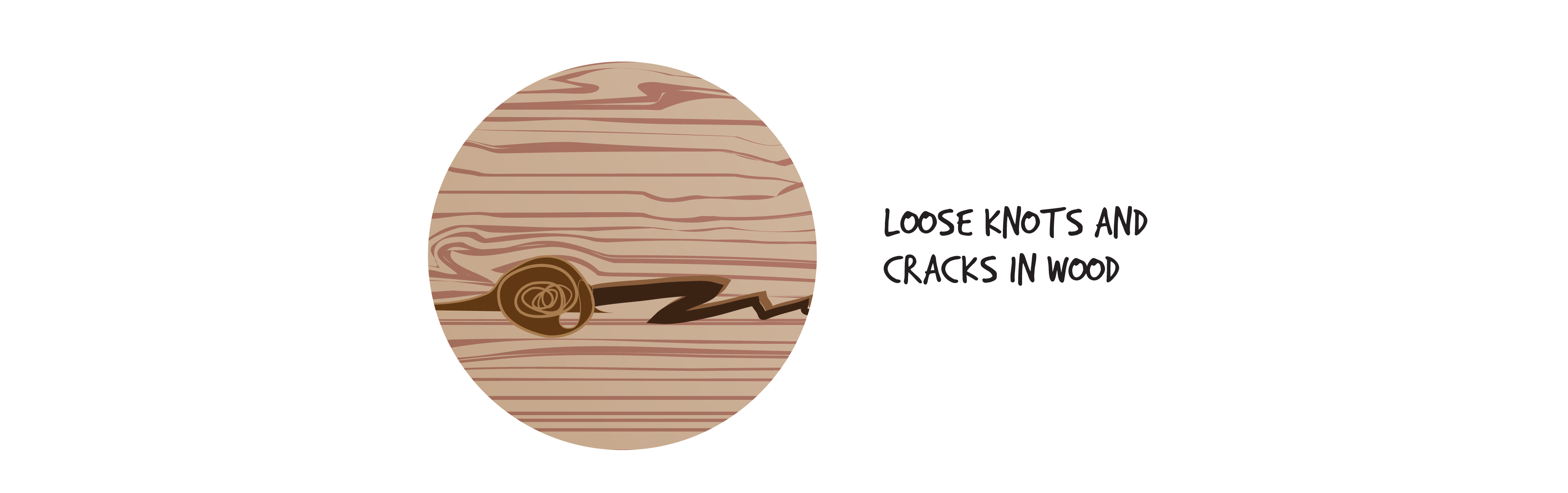

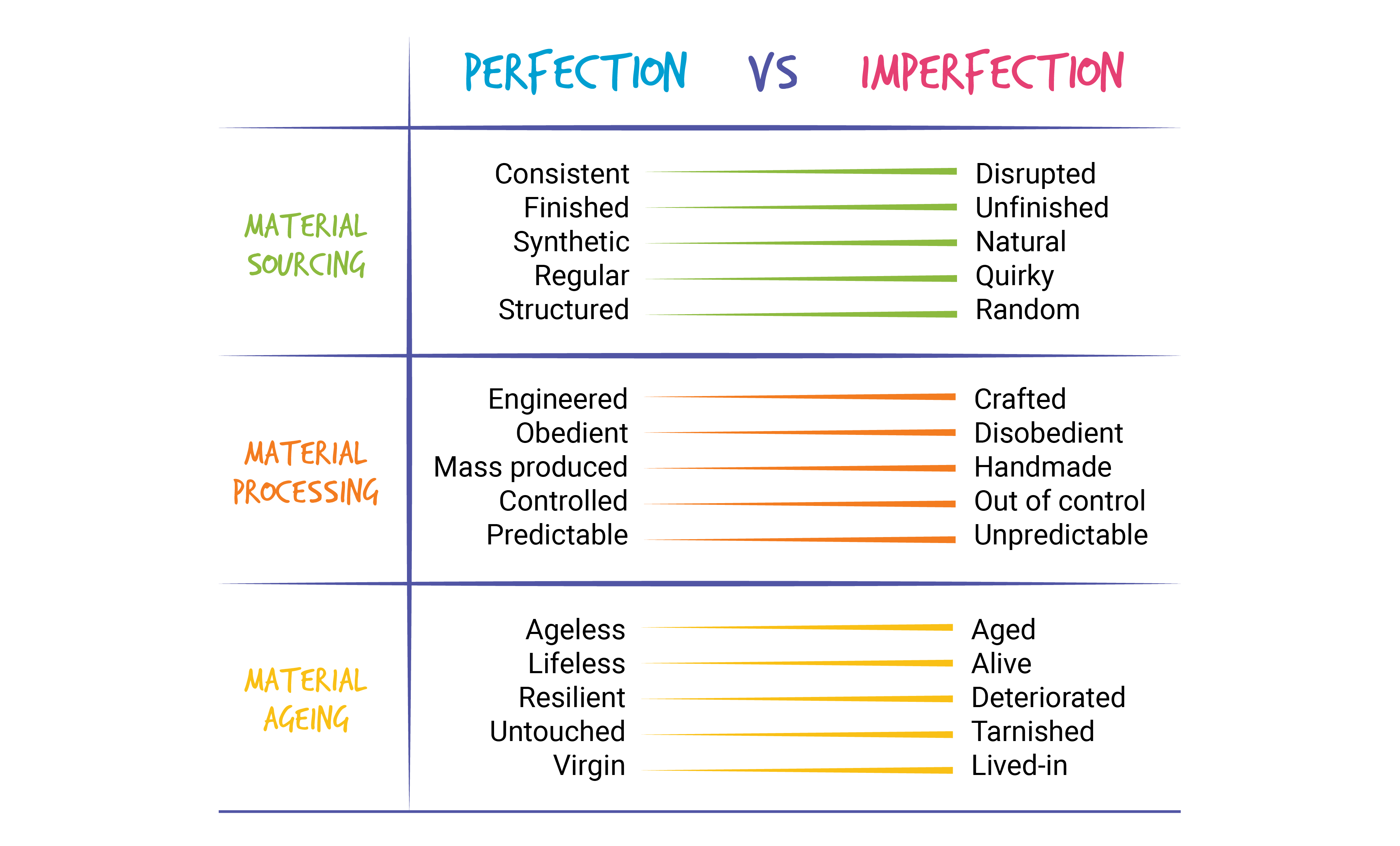

1. Material sourcing. This refers to naturally or mechanically occurring surface disturbances that seem to be part of the material. We see this in wood grain and textures, uneven surfaces of recycled plastic products, and intentionally distressed materials used in jeans.

Surface disturbances from material sourcing

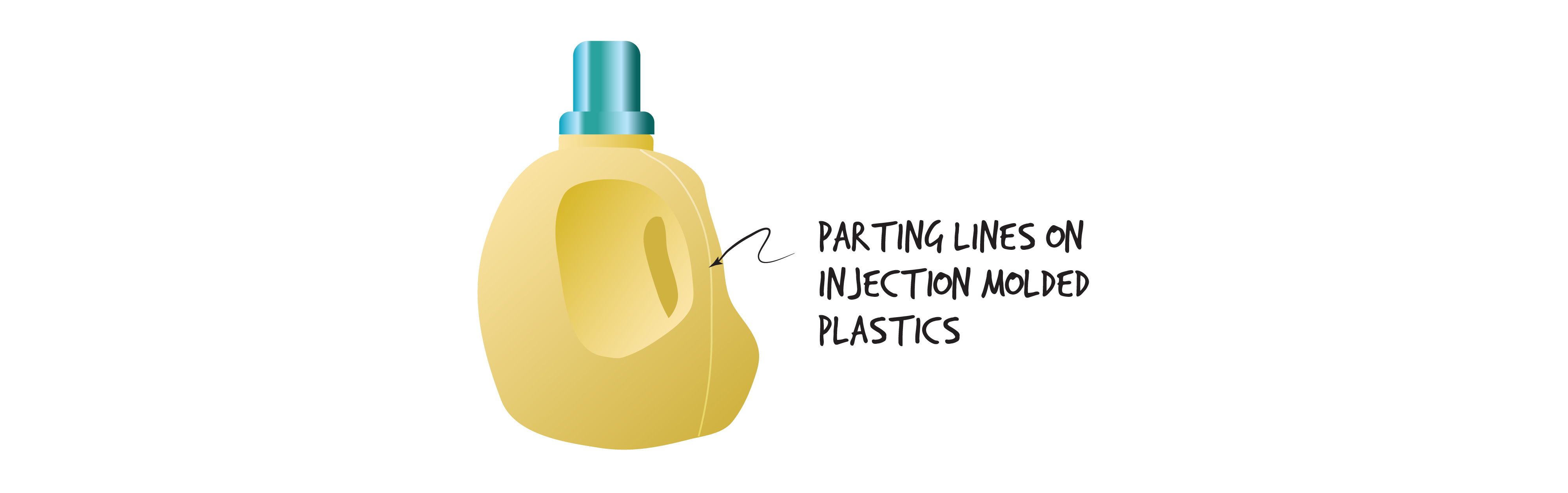

2. Material Processing. This refers to traces of the production effects such as ejection pin indentations on injection moulded plastics or other intentional or unintentional surface irregularities caused by the shaping and finishing.

Production effect from the manufacturing process

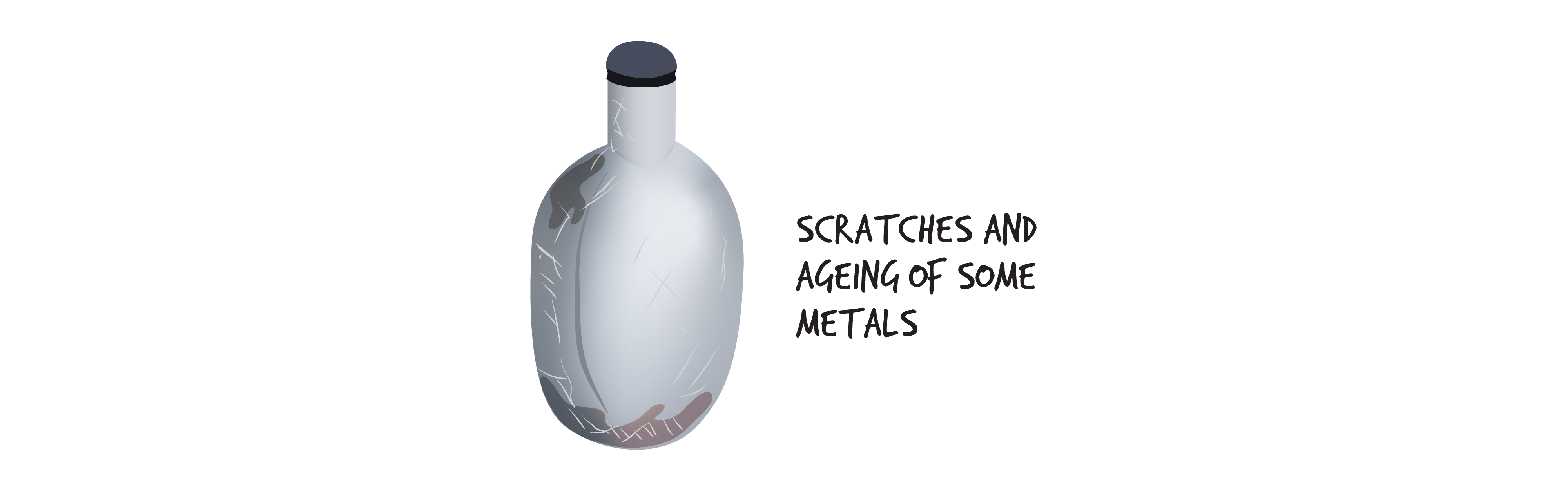

3. Material changes over time. This refers to how surfaces respond to degrading material properties such as becoming more brittle, maturing over time like worn leather or wood, or ageing over time where scratches and patinas develop on metal surfaces.

Degrading material properties

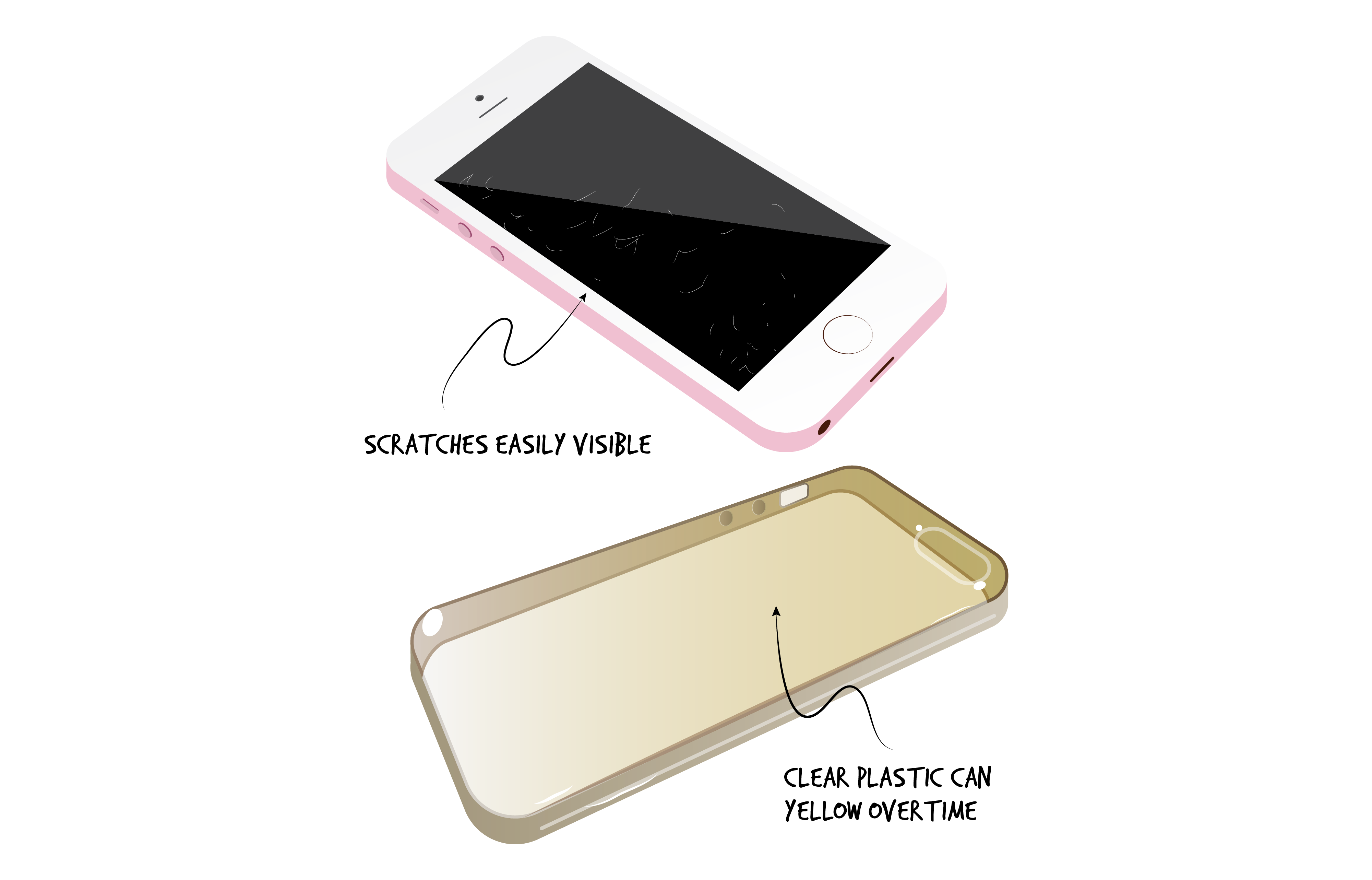

4. Everyday wear-and-tear. This refers to the different kinds of damage that result from ongoing interactions, either sudden or accumulative: impacts from dropping, chipping, abrasion, or dirt build-up.

Everyday wear and tear on cell phone and accessory surfaces

Qualities of surface perfections and imperfections (adapted from Pedgley et al, 2018, Pedgley, 2014)

Pedgley and his team developed categories for four kinds of material surface imperfections based on their studies of people’s responses to the nature of the surfaces:

- Negative Perfect. Products in this category have ‘perfect’ surfaces (shiny, smooth, glossy, or uniform) however, study participants described them negatively as being too synthetic, too boring, or too sterile.

- Positive Perfect. Products in this category have ‘perfect’ surfaces (mirror-like gloss or strikingly flat) and study participants described them positively as displaying superior engineering.

- Negative Imperfect. Products in this category have ‘imperfect’ surfaces (unfinished appearance, worn out, or defective) and participants described them negatively as undesirable imperfections.

- Positive Imperfect. Products in this category have ‘imperfect’ surfaces (handmade, smoothed over from ageing, natural organic textures, etc.) and participants described them as positively expressing value, uniqueness, or charm.

Activity Time!

Drag each item to the diagram quadrant that you think they best correspond to based on the item’s material surface imperfections.

Material surface imperfection diagram adapted from Pedgley (2014)

Next section: 4.6 Meanings Associated with Material Sensations