Part 3: Fuels and Combustion

Fuels and Combustion

Solid Fuels

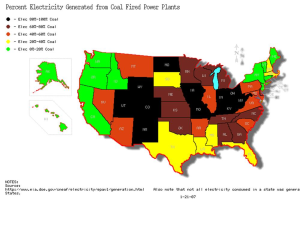

Coal is a fossil fuel formed in ecosystems where plant remains were saved by water and mud from oxidization and biodegradation. Coal is a readily combustible black or brownish-black rock. It is a sedimentary rock, but the harder forms, such as anthracite coal, can be regarded as metamorphic rocks because of later exposure to elevated temperature and pressure. It is composed primarily of carbon along with assorted other elements, including sulfur. It is the largest single source of fuel for the generation of electricity world-wide, as well as the largest world-wide source of carbon dioxide emissions.

Biomass is material derived from recently living organisms. This includes plants, animals and their by-products. For example, manure, garden waste and crop residues are all sources of biomass. It is a renewable energy source based on the carbon cycle, unlike other natural resources such as petroleum, coal, and nuclear fuels.

Biomass fuels:

-

-

- Composed mostly of cellulose and moisture.

- Generate less NOx (nitrogen oxides) and SO2 (sulphur dioxide) emissions than fossil fuels.

- Require preparation before being fed into the boiler

-

Biomass Fuel Preparation:

-

-

- Receiving: truck tipper, conveyor, and radial stacker.

- Processing: reclaim feeder, conveyor, metal separator, dryer, screener, and grinder.

- Buffer storage: storage bin (24 hours).

- Fuel metering conveyors, meters, and pneumatic transport

-

Garbage and waste materials are a type of solid fuel. They can also be used to produce steam. Solid wastes can be disposed of by incineration (burning). Heat recovery and strict air pollution guidelines are required for refuse incinerators. The basic incinerators are large enough to provide steam for turbine generator sets and commercial power production.

Solid fuels are first burned on grating systems:

Activity: Types of Grating Systems

Click the arrows to view the different types of grating systems for solid fuels.

Travelling grates

|

Pinhole grate

|

Vibrating grates

|

Heating Values and Specific Weight of Various Wood Fuels

| Moisture Unit Fuel | MJ/kg | 30 % MWh/t | kg/m3 | MJ/kg | 50 %

MWh/t |

kg/m3 |

| Hogged wood | 12.9 | 3.6 | 720 | 8.5 | 2.3 | 1030 |

| Sawmill waste | 12.7 | 3.3 | 610 | 8.4 | 2.4 | 840 |

| Chips | 13.0 | 3.8 | 510 | 8.2 | 2.2 | 720 |

| Sawdust | 12.9 | 3.6 | 590 | 8.3 | 2.3 | 830 |

| MJ/kg | MWh/t | |

| Light fuel oil | 42.7 | 11.9 |

| Heavy fuel oil | 40.7 | 11.3 |

| Lignite coal | 25 | |

| Sub-bituminous | 27 | |

| Anthractite coal | 29 | |

| Bituminous coal | 31 – 35 |

Coal Properties

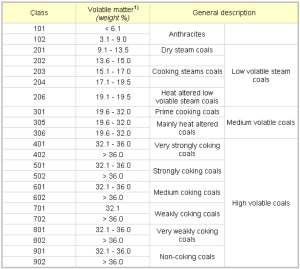

Coals are divided into classes or groups according to various characteristics: Percentage of fixed carbon, Volatile matter, and Heating value.

Formation of Coal

Organic matter accumulating is greater than the amount decomposing (because of reducing conditions). Organic matter builds up to form peat.

-

- Peat is compressed to form lignite

- Brown coal

- Lignite is compressed and volatile compounds are lost to form bituminous coal

- Soft coal

- Bituminous coal is further compressed and heated to form anthracite

- Hard coal

- Peat is compressed to form lignite

Classes of Coal

There are 3 Classes of coal- Anthracite, Bituminous, and Lignite.

-

Anthracite:

Anthracite is harder than any other type of coal. It has a high percentage of fixed carbon, over 92%, and less than 8% volatile matter. It ignites slowly but burns at a high temperature with a short clear flame. Anthracite does have a high cost and a high sulphur content, which contributes to environmental emissions. The moisture content is less than 15 percent and the heat content ranges from 22 to 28 million Btu per short ton (26 to 33 MJ/kg)

Semi-Anthracite

-

-

-

- Burns with a short clear flame.

- Contains between 86% and 92% fixed carbon and between 8% and 14% volatile matter.

- Very expensive and thus its use in power plants is limited.

-

-

2. Bituminous

Generally considered to be the best suited for power plants due to reasonable cost and availability. The carbon content of bituminous coal is around 60-80%.

Has several subdivisions according to the volatile content.

-

- Low volatile bituminous – 14% to 22% volatile matter.

- Medium volatile bituminous – 22% to 33% volatile matter.

- High volatile bituminous – over 31% volatile matter.

Heat content of bituminous coal ranges from 21 million to 30 million Btu/ton (24 to 35 MJ/kg). Usually black, sometimes dark brown in colour.

Sub-Bitminous

-

-

-

- High moisture content

- May be dull, dark brown to black, soft and crumbly

- Contains 20-30% inherent moisture by weight.

- Heat content of sub-bituminous coal ranges from 17 to 24 million British thermal units (Btu) per short ton (20 to 28 megajoules per kilogram).

-

-

3. Lignite

Lignite is referred to as brown coal. It is the lowest rank of coal and used as fuel for steam-electric power generation. Lignite has a high moisture content, as high as 66 percent, and very high ash content. The heat content of lignite ranges from 10 to 20 MJ/kg (9 to 17 million Btu per short ton).

Activity: Coal Production Charts

Click on the arrows to view coal production

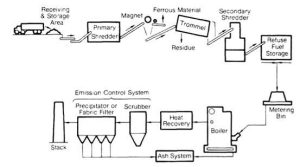

Refuse Fuels

There are two main techniques of burning refuse.

- Mass burning

- RDF (Refuse Derived Fuel)

Refuse-derived fuel (RDF) is a fuel produced from various types of waste such as municipal solid waste (MSW), industrial waste or commercial waste.

- Trucks deliver the refuse.

- Fed into the primary shredder.

- Fed over a magnetic separator, removing any ferrous materials.

- Passes to the secondary shredder to reduce the size of the pieces.

- Stored before being metered into the boiler.

- Combustion takes place on the grates as they move along the bottom of the furnace.

- Non-combustible material and ash drop into the ash pit at the end of the grate.

- Boiler ash and flyash from the scrubbers and precipitators are disposed of in the ash system.

Video: How Do You Generate Electricity Using Coal ?

Watch “How Do You Generate Electricity Using Coal?” [9:27].

Coal is unloaded from the ships, trains, or large coal haulers.

Beneath the coal storage area are reclaim hoppers. These hoppers dump the coal on to the reclaim belt which takes it to the coal breakers. Fast high-capacity unloading can also weigh the load. Watch the video to see a rotary railcar dumper wagon tippler in standard operations.

Video: Rotary Railcar Dumper Wagon Tippler During Operations

Watch “ Rotary Railcar Dumper Wagon Tippler during operations” [0:34].

Coal towers with clamshell have a bucket that lifts coal from barges and delivers it to the conveyor.

Video: Clamshell During Operations

Watch “ You Missed the Hopper” [0:35] to view a missed clamshell operation.

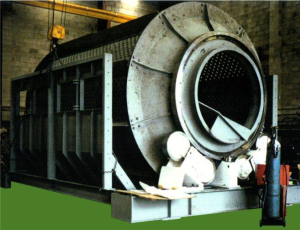

Coal Breakers

Coal passes into the breaker feed end, and the fine pieces are immediately screened out.

-

- Larger lumps are lifted by the shelves and dropped down to the screen.

- These lumps are broken down by gravity impact.

The cylinder rotates at 12 to 20 rpm inside a steel casing with a hopper bottom which collects the coal that passes through the screen plates.

Harder lumps of coal are exit from the rear of the breaker into a hammer mill

- Crushes the coal to nominal size

- The hammer mill also removes tramp metal from the coal.

Activity: Types of Crushers

Click the arrows to view images of 3 types of crushers. Hover the cursor over to reveal the name

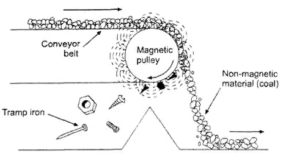

Magnetic Pulley

When the coal leaves the breaker on its way to the belt weighing machine it passes over a magnetic pulley which removes tramp iron from the coal.

Belt Weighing Machine

As the speed of the belt is known, the amount of coal passing over the belt in a period of time is determined. The belt weighing machine has a built in weight indicating sensor, or load cell, measuring the weight or mass of material on the belt.

Plant Hoppers

Coal is moved by conveyor to the plant hoppers or bunkers. Normally each bunker supplies a feeder that supplies a pulverizer, fluid bed or cyclone. The bunker has a capacity of three to twelve hours, depending on the boiler load and plant design. Plant hopper drops the coal into the coal feeder which controls the flow of coal into the pulverisers. The speed of the belt varies with the boiler load and is controlled by the boiler master controller.

Coal Pulverizers

The two most common pulverisers are:

-

-

- Ball-race mill

- Ring-roll mill

-

The pulverized coal is carried to the burners by the airflow through the pulverizer.

Activity: Images of Pulverizers

Click the arrows to view images of Pulverizers.

Activity: Ball-Race Mills

Click through the slides to learn about Ball-Race Mills.

Ball-race mill

-

-

- Coal is ground between the ball and the two rings.

- When the coal is ground fine enough the air flow through the mill carries it away to the burners.

-

Ring-roll mill or Bowl mill

-

-

-

- The pulverized coal is carried to the burners by the airflow through the pulverizer.

-

-

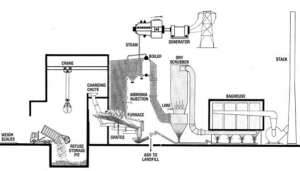

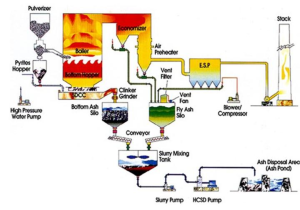

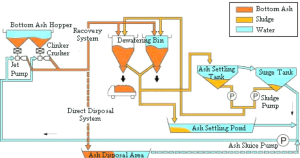

Ash Handling

There are two types of ash that need to be removed from the boiler and the downstream ducting.

- Bottom Ash– Ash that is removed from the bottom of the furnace.

- Flyash– Carried out of the furnace with the flue gas flow. Must be removed from the flue gas flow before it exits the stack.

Video: Inside a Coal Fired Boiler

Watch the video “Inside a Coal Fired Boiler” [ 1:30].

Ash Removal

Ash and slag dropping out of the furnace is quenched in water-filled bottom ash hoppers. When the ash is removed from the hopper, a sluice gate opens, and the ash grinder starts.

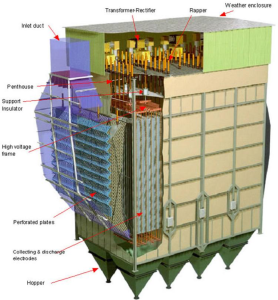

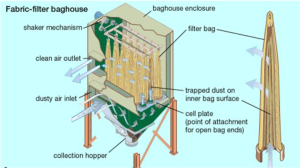

Dust Collectors

The two most common types are the centrifugal collector and the electrostatic precipitator.

Centrifugal Collectors

|

Electrostatic Precipitators

|

Flyash

Is removed from the hoppers by high velocity air and carried to a flyash silo where it is deposited in hoppers. The air that carried the ash to the silo is filtered before it is exhausted to the atmosphere. The dry ash may be hauled away for use in such products as cement. The ash can also be mixed with water and trucked away for disposal.

Pyrites

- The mineral pyrite, or iron pyrite

-

- Iron sulfide with the formula FeS2

- Found in boiler bottom ash

- Removed from the ash with magnets

- Fool’s gold because of its resemblance to gold.

-