Part 2: Steam Distribution Systems

Steam Distribution Systems

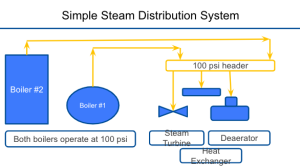

Simple Steam Distribution System

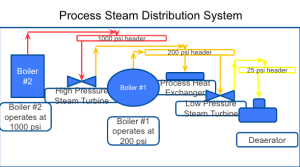

Different plant designs have specific temperatures and pressures.

A portion of the steam leaving the boiler is used for various process at varying pressures:

-

-

- Heat exchangers

- Feedwater heating

- Steam tracing

- Hot lime softening

- Deaeration.

-

Process Steam Distribution System

Pressure Reduction

Pressure reducing valve (PRV) is most common.

A separator is installed upstream of the reducing valve to remove entrained water. The Plant downstream of the pressure reducing valve is protected by a safety valve in case the pressure reducing valve fails

Steam Separators

Remove both droplets of water from pipe walls and suspended mist entrained in the steam itself. They are recommended before control valves and flowmeters. Also used where a steam main enters a building from outside.

Strainers

-

- Used to remove particles from steam.

- i.e. rust

- Used to remove particles from steam.

Pressure Reducing Station

Main disadvantage

-

- Loss of energy in the reduction of pressure across the valve.

- The pressure is reduced with no work being done.

- An Extraction or Topping turbine will also reduce pressure but also drives a generator producing electricity.

Steam Headers

Proper pipe alignment and drainage rules:

-

- Steam lines should be arranged to fall in the direction of flow.

- Steam lines rising in the direction of flow should slope at not less than 250 mm per 10 metres of pipe.

- Steam lines should be drained at regular intervals of 30-50 m and at any low points in the system.

- Branch connections should always be taken from the top of the main from where the driest steam is taken.

- Separators should be considered before any piece of steam using equipment ensuring that dry steam is used.

- Traps selected should be robust enough to avoid waterhammer damage and frost damage.

- Must have provisions for expansion and support

- Shouldn’t transmit forces to the steam turbine.

- Steam lines should be arranged to fall in the direction of flow.

Operation

-

- Steam distribution systems require attention

- Especially during startup and shutdown situations.

- Steam distribution systems require attention

Startup

-

-

-

- Inspect steam piping prior to being put into service to insure:

- Repairs have been completed

- Insulation has been reinstalled

- Anchor points and piping supports are in place

- Safety valves and vents are in a ready to run position

- Steam trap isolation valves are open — some drains to atmosphere may be opened until they are blowing dry steam

- The piping system pressure and temperatures are increased gradually.

- Steam vents and reducing stations are checked for proper operation.

- The piping is physically checked for signs of leaks

- Piping anchors and expansion are checked.

- Inspect steam piping prior to being put into service to insure:

-

-

Normal Operation

-

- Inspect system routinely.

- Note any leaks or required repairs

- Steam traps can normally be replaced with the system online.

- Note any water hammer during normal operation

- Inspect system routinely.

Shutdown

-

- The steam pressure and temperatures in the system are reduced.

- When pressure is low, open steam line drains to let condensate out

- Once cooled the system drains and vents are then closed to prevent any air and oxygen from entering the system.