9.2 Reverse Logistics

Learning Objective

1. Explain the concept of Reverse Logistics.

Until this chapter, the major focus was on activities related to forward logistics where raw material moves from suppliers and reaches consumers in the finished form. In this section, activities concerning reverse logistics will be explained.

According to Cambridge Dictionary, “reverse logistics is the process of dealing with goods that have been returned to the company by customers” (Cambridge Dictionary, 2022).

For example, the customer would like to return or recycle products or goods, and this process requires reverse logistics. Therefore, activities such as recovery, return, reuse or disposal of discarded products are part of reverse logistics activities. In short, when products return from the final destination or user to another location for final disposal or recapturing value, the process is called reverse logistics.

A great example is Amazon which has no-fuss return policies and innovative reverse logistics. In addition, it provides excellent reverse logistics training programs. Amazon’s reverse logistics focus on managing and running warehouses in a sustainable way. It also helps organizations build trust between logistics service providers, manufacturers, and customers. Moreover, a company has full control over a product’s life from start to the end involving decisions relating to recycling, refurbishment, repair, warranty, disposal of discarded products, etc.

Let’s take the example of E-commerce which is a fast-paced industry, and businesses use fast, free and easy return policies. Though it attracts customers, but also increases the volume of returned products. . For consumers, returns could be a motivator to shop with a particular online retailer but for retailers, it is adding to huge costs.

It is exciting that reverse logistics has existed for the last 100 years, and it is a part of the retail industry. The size of reverse logistics market worldwide has been significantly increasing. Let’s watch this video that explains retail reverse logistics.

Video: Retail Reverse Logistics (6:36)

Usually the study of retail supply chain management focuses on goods going out to the customer. This article offers a conceptual framework for the management of products flowing in the opposite direction. “Retail Reverse Logistics” is concerned with the achievement of optimal efficiency for all the post- sale activity associated with a product. This is not a new subject but the growth of internet and home shopping has significantly increased the volume of returned goods.

Media 9.2 Retail Reverse Logistics. [Video]. Cranfield School of Management. (URL: https://www.youtube.com/watch?v=x6NiqMEnvos)

For more details on how e-returns could be costly, E-commerce return rates by industry, reasons of returns, strategies of handling e-commerce returns and impact of COVID-19, read though the first two sections of article: The Plague of Ecommerce Return Rates and How to maintain Profitability.

According to Statista (2021), the size of the reverse logistics market globally will be continuously expanded and projected to reach 958.3 billion U.S. dollars by 2028 (Statista, August 4, 2021). As evident from the graph, a significant part of reverse logistics, electronic waste (e-waste), has become one of the fastest-growing fields. View graph Size of the reverse logistics market worldwide from 2020 to 2028 (in billion U.S. dollars) [Chart description].

The following material adapted from E-Waste Reverse Supply Chain: A Review and Future Perspectives by Linh Thi Truc Doan, Yousef Amer, Sang-Heon Lee, Phan Nguyen Ky Phuc, & Luu Quoc Dat, 2019, under a Creative Commons Attribution License.

With the significant amount of upgrading of electronic devices, electronic waste (e-waste) is one of the fastest-growing types of waste. For instance, 80% of mobile phones have been upgraded every two years, which leads to a large number of discarded products Which leads to E-waste RSC (Reverse Supply Chain) systems. It is a dynamic system with a high level of uncertainties in quantity, quality, and time of returned products. Firstly, there are three main sources of e-waste generation, including households, industries, and institutional sources (i.e., schools, hospitals, and governmental agencies). Secondly, e-waste collection is derived from municipality collection points, electronic industries, retailers, and informal and formal recycling sectors. Informal recycling activities are common in developing countries, such as India and South Africa, where recycling methods are rudimentary, and a significant proportion of e-waste components end up in uncontrolled landfills.

To mitigate the amount of product disposal, industries have been carrying out 6R concept (namely, Reduce, Reuse, Recycle, Recover, Redesign, and Remanufacture) to improve recovery implementation and minimize non-value-added activities within end-of-life (EoL) management. Companies gain many benefits by implementing product EoL treatment, such as financial benefits to companies, product usage, increasing market share, improved public reputation, and competitive advantage.

Did You Know?

In today’s business world with a competitive electronics market, the production of electronic equipment is rapidly growing because customers are likely to own the latest models with more advanced functions and attractive designs. This leads to the amount of e-waste growing speedily, reaching around 41.8 million tonnes in 2014. The quantity of e-waste produced is approximately three times faster in comparison with other wastes. The amount of e-waste is estimated to reach 52 million tonnes or 6.8 kg per capita in 2021. However, around 20% of all e-waste generated is officially collected and recycled. For example, the average lifespan of a new computer in India has reduced from seven years to four years. Most e-waste was generated in Asia (16 million tonnes) whereas the least e-waste generation (0.6 million tonnes) was in Australia in 2016. The highest e-waste per resident (15.6 kg per capita) was in Europe, while Africa produced the lowest quantity of e-waste per capita (1.7 kg per capita). Both North and South Americas released around 11.7 million tonnes, which was equal to 12.2 kg per capita.

(Doan et al., 2019) CC-BY-4.0

The following material adapted from Sustainability, Innovation and Entrepreneurship by Larsen (2020) under a Creative Commons Attribution-NonCommercial-ShareAlike License.

There are different ways to handle customer returns. Many companies already have rudimentary reverse logistics systems to deal with customers’ returns of items they do not want or that were found defective or otherwise unsatisfactory. An expanded reverse logistics system would ultimately replace the linearity of most production methods—raw materials, to processing, to further conversions and modification, to ultimate product, to use, to disposal—with a cradle-to-cradle, cyclical path or closed loop that begins with the return of used, outmoded, out-of-fashion, and otherwise “consumed” products. The products are either recycled and placed back into the manufacturing stream or broken down into compostable materials. The cycle is never ending because materials return to the land in safe molecular structures (taken up and used by organisms as biological nutrients) or are perpetually used within the economy as input for new products (technical nutrients).

Companies typically funnel spent items from consumers into the reverse supply chain by leasing their products or providing collection points or by other means of recovering the items once their service life ends.

Once collected, whether by the original manufacturer or a third party, the products could be inspected and sorted. Some items might return quickly to the supply chain with only minimal repair or replacement of certain components, whereas other products might need to be disassembled, remanufactured, or cannibalized for salvageable parts while the remnant is recycled or sent to a landfill or incinerator. Moreover, the reverse supply chain might spawn new suppliers as well as other sources of revenue for companies that engage in collection, disassembly, and so on, making the entire network more efficient.

(Larson, 2020) CC-BY-NC-SA-4.0

Forward and Reverse Supply Chain

The following material adapted from E-Waste Reverse Supply Chain: A Review and Future Perspectives by Linh Thi Truc Doan, Yousef Amer, Sang-Heon Lee, Phan Nguyen Ky Phuc, & Luu Quoc Dat. (2019) under a Creative Commons Attribution License.

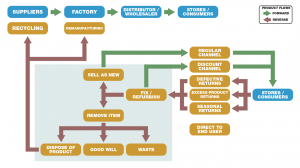

A reverse supply chain differs significantly from a forward supply chain in a wide range of aspects. Figure 9. 2 outlines the process of forward and reverse logistics.

(Doan et al., 2019) CC-BY-4.0

Forward logistics is the same as traditional logistics, starting from the suppliers through the factory and then moving to the distributor/wholesaler. Finally, the product moves to retailers and final customers. Forward or traditional flow is a green arrow in figure 9.2. On the other hand, reverse logistics starts from the opposite side- customers and moves to the first point of the supply chain according to a return policy of the product. Reverse logistics is a brown line in figure 9.2.

Figure 9.2

Forward and Reverse Logistics Processes

The following material adapted from E-Waste Reverse Supply Chain: A Review and Future Perspectives by Linh Thi Truc Doan, Yousef Amer, Sang-Heon Lee, Phan Nguyen Ky Phuc, & Luu Quoc Dat. (2019) under a Creative Commons Attribution License.

Table 9.1 shows a summary of the main differences between forward and reverse logistics. Reducing cost and increasing profit are considered as two vital goals in forward supply chains, while reverse supply chains focus on environmental regulations, cost minimization as well as profit maximization.

Table 9.1

Differences between forward and reverse supply chains

| Forward Supply Chain | Reverse Supply Chain |

|---|---|

| Focus on increasing profit and cost minimization | Focus on environmental issues, regulations, profit and cost minimization |

| Product demand is quite straightforward to forecast | Returned products are relatively difficult to estimate |

| The quantity of product is less variation | The quantity of returned products are highly uncertain |

| Conventional marketing techniques can be used | There are some elements requiring complicated marketing |

| Processing times and stages are well identified | Processing times and stages are vary based on the quality of returned products |

| Products are delivered from one location to other locations | Used products are collected from a lot of locations and then reach to one processing center |

| Speed is one of the main factors in terms of competitive advantage | Speed is not an important element |

| Product packaging is standard | Returned product packaging highly varies or lack of packaging |

| Product structure is standard | Returned product structure is modified |

| Cost estimation is quite easier because of accounting systems | Cost factors are complicated to determine |

| Disposition options are rather clear | Disposition alternatives depended on the condition of a returned product |

| Inventory management is consistent | Inventory management is chaotic |

| Cost implications are quite clear | Cost implications are unclear |

| Processes for real-time product tracking are highly visible | Processes for returned product tracking are less visible because of lack of information system infrastructure |

| Product life cycle changes are easily managed | Product life cycle changes are difficulty managed |

| Models are relatively deterministic | Models are more stochastic |

| Key importance to manufacturers | Key importance to end-of-life processors (such as remanufacturers, recyclers) |

(Doan et al., 2019) CC-BY-4.0

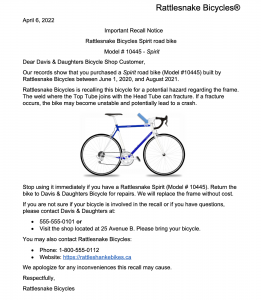

Recalls

Recalls products mean officially retrieving products from manufacturers or users to the place of origin because discovered defects can harm consumers, hinder performance or realize more cost-effective product production. The request to recall products can be by the government or company in the form of a letter shown below. This official act helps prevent and reduce risks related to injuries or safety concerns. In this scenario, companies provide consumers with compensation. Recalls can be mandated by Safety Commissions or voluntary. Please follow the link for more examples of recalls in Canada.

On the other hand, activities such as recovery, return, reuse or disposal of discarded products are part of reverse logistics activities. In short, when products return from the final destination or user to another location for final disposal or recapturing value. This process is so-called reverse logistics.

Figure 9.3

Rattlesnake Bicycles

Note. Rattlesnake Bicycles recall notice. [Image description].

Check Your Understanding

Explain the concepts of reverse logistics and recalls.

Answer the question(s) below to see how well you understand the topics covered above. You can retake it an unlimited number of times.

Use this quiz to check your understanding and decide whether to (1) study the previous section further or (2) move on to the next section.

Interactive activity unavailable in this format

Text-based alternative to interactive activity available in Chapter 9.7.

Overall Activity Feedback

Recall products mean officially retrieving products from manufacturers or users to the place of origin because discovered defects can harm consumers, hinder performance, or realize more cost-effective product production. The request to recall products can be by the government or company. This official act helps prevent and reduce risks related to injuries or safety concerns. In this scenario, companies provide consumers with compensation. Recalls can be mandated by Safety Commissions or voluntary. “Reverse logistics is the process of dealing with goods that have been returned to the company by customers” (Cambridge Dictionary, 2022).

It is essential to know that recalling products means officially retrieving products from manufacturers or users to the place of origin because discovered defects can harm consumers, hinder performance, or realize more cost-effective product production. The request to recall products can be by the government or company. This official act helps prevent and reduce risks related to injuries or safety concerns. In this scenario, companies provide consumers with compensation. Recalls can be mandated by Safety Commissions or voluntary.

On the other hand, activities such as recovery, return, reuse or disposal of discarded products are part of reverse logistics activities. In short, when products return from the final destination or user to another location for final disposal or recapturing value. This process is so-called reverse logistics.

Media Attributions and References

Cranfield School of Management. (2012, June 14). Retail reverse logistics [Video]. YouTube. https://www.youtube.com/watch?v=x6NiqMEnvos