5.2 Inbound and Outbound Storage

Learning Objective

1. Explain the importance of storage in global value chain and the concepts of inbound and outbound storage.

Importance of Storage in Warehousing

The Logistics Cycle (discussed in chapter 2) is a complex process involving a series of stages that must run smoothly to ensure that goods reach their destination on time and in good condition. One of those stages is Storage, which plays a vital role in distribution logistics. In the logistics cycle, Storage includes both Warehousing and Inventory Management.

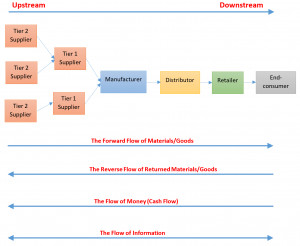

Let’s look at the main flows in value chain to understand importance of storage. There are three types of main flows that happen in any value chain (outlined in Figure 5.2):

- The flow of materials/goods,

- The flow of money/cash, and

- The flow of information.

There is a regular forward flow of materials/goods that happens all the way from higher-tier suppliers (upstream) to the end-consumer (downstream). In addition, if there are returns for any reason, there will be a reverse flow of materials/goods in the opposite direction to the forward flow.

The flow of money (cash flow) happens from downstream to upstream. For example, the retailer needs to pay the distributor for the goods they have received. from them.

The flow of information happens both ways in the supply chain since organizations will need to share a different type of information so that the whole supply chain can make better decisions to improve overall performance.

Main Flows in Value Chain

Note. From Faramarzi & Drane, n.d. CC BY-NC-SA 4.0. [Image description].

When materials move from upstream to downstream or vice versa, there arises a need to store goods either at specific destinations or while in-transit. Efficient storage helps to:

- guarantee consumer satisfaction by maintaining good delivery times

- Reduce warehouse losses by keeping a track of goods coming in and going out of the storage facility

- Offer better services which ultimately increases profit

Video: Inside Amazon’s Smart Warehouse (10:48)

Watch this video to see amazing facts about Amazon’s Storage Management.

Media 5.1. Inside Amazon’s Smart Warehouse [Video]. Tech Vision.

Storage of goods received by a firm is known as ‘Inbound Storage’, and storage of goods which are scheduled to move out of a firm is known as ‘Outbound Storage’. In some cases, companies have different storage facilities to manage inbound and outbound storage. As per Jenkins, 2020:

Inbound Storage includes managing the materials before they go to manufacturing or customer fulfillment. This department is responsible for making sure items are placed in logical locations for fulfillment and the right storage conditions are met. A company keeps a certain quantity of goods on hand to meet demand. Outbound Storage Facilities help store these goods securely in the right conditions and organize them.

Material handling is an integral part of Inbound and Outbound Storage. Therefore, it is important to discuss it here before moving on to the subsequent sections on Warehousing and Inventory Management.

Material handling relates to transporting raw materials, finished goods and other kinds of inventories within the manufacturing unit, and out of the unit to warehouses, distribution centers or directly to consumers (Rosenblatt, 2001, p-492). It is estimated that 20% to 50% of the total operating expenses within manufacturing are attributed to material handling (Tompkins et al., 1996). Material handling activities may account for 80% to 95% of total overall time spent between receiving a customer order and shipping the requested items (Rosaler and Rice, 1994).

The Ministry of Labour, Training and Skills Development, Canada recognizes the importance of material handling and specifies that:

The efficient handling and storing of materials are vital to industry. Activities involving material handling enable the supply of raw materials as well as a continuous flow of parts and assemblies through workplaces and ensure materials are available when needed.

Many manufacturing companies have adopted computerized systems to control the flow of resources and inventory. Materials requirement planning (MRP) is one such system. MRP uses a master schedule to ensure that the materials, labor, and equipment needed for production are at the right places in the right amounts at the right times. The schedule is based on forecasts of demand for the company’s products. It says exactly what will be manufactured during the next few weeks or months and when the work will occur. MRP also helps to ensure the smooth flow of finished products.

Some manufacturing firms have moved beyond MRP systems and are now using Enterprise Resource Planning (ERP) systems. ERP systems provide an integrated and continuously updated view of core business processes using shared databases maintained by a database management system. ERP systems track business resources—cash, raw materials, production capacity—and the status of business commitments—orders, purchase orders, and payroll. The applications that make up the system share data from and between various departments (e.g., manufacturing, purchasing, sales, accounting, etc.). ERP facilitates information flow between all business functions and manages connections to outside stakeholders.

Video: Introducing The Material Handling and Logistics Industry (5:40)

Watch this video to know more about material handling and logistics industry.

Media 5.2. Introducing The Material Handling and Logistics Industry [Video]. MHI.

Check Your Understanding

Answer the question(s) below to see how well you understand the topics covered above. You can retake it an unlimited number of times.

Use this quiz to check your understanding and decide whether to (1) study the previous section further or (2) move on to the next section.

Check Your Understanding: Inbound and Outbound Storage

Overall Activity Feedback

The Logistics Cycle is a complex process involving a series of stages that must run smoothly to ensure that goods reach their destination on time and in good condition. In the logistics cycle, Storage includes both Warehousing and Inventory Management. There is a forward flow of materials/goods for the regular flow that happens all the way from higher- tier suppliers (upstream) to the end-consumer (downstream). In addition, if there are returns for any reason, there will be a reverse flow of materials/goods in the opposite direction to the forward flow. Material Handling is an integral part of Inbound and Outbound Storage. Many manufacturing companies have adopted computerized systems such as Materials requirement planning (MRP) to control the flow of resources and inventory.

Media Attributions and References

Faramarzi, H. & Drane, M. (n.d.). Introduction to operations management. Seneca College Pressbooks System. https://pressbooks.senecacollege.ca/operationsmanagementintro/. CC BY-NC-SA 4.0.

MHI. (n.d.). Introducing the material handling and logistics industry [Video]. YouTube. https://www.youtube.com/watch?v=dEtn3P2kFFI.

Tech Vision. (n.d.). Inside Amazon’s smart warehouse [Video]. YouTube. https://www.youtube.com/watch?v=IMPbKVb8y8s.

The act of storing something in a warehouse.

Supplier side

Consumer side

A system that ensures that the materials, labor, and equipment needed for production are at the right places in the right amounts at the right times.

ERP systems provide an integrated and continuously updated view of core business processes using shared databases maintained by a database management system.