8.8 Key Terms, References, and Accessibility Descriptions

Key Terms

Sustainable – “causing, or made in a way that causes, little or no damage to the environment and therefore able to continue for a long time” (Cambridge dictionary, 2022)

Chapter References

Circular Economy: Strategies and Policies. (2021). Field Actions Science Reports, 23, 4–7. https://journals.openedition.org/factsreports/6515

Dwivedi, A., Agrawal, D., Jha, A., Gastaldi, M., Paul, S. K., & D’Adamo, I. (2021). Addressing the challenges to sustainable initiatives in value chain flexibility: Implications for sustainable development goals. Global Journal of Flexible Systems Management, 22, 179–197. https://link.springer.com/article/10.1007/s40171-021-00288-4

FITT. (2013). FITTskills: International trade management (6th ed.). Forum for International Trade Training

Gargalo, C. L., Pons, E. P., Barbosa-Povoa, A. P., & Carvalho, A. (2021). A lean approach to developing sustainable supply chains. Sustainability, 3(7), 3714. https://www.mdpi.com/2071-1050/13/7/3714/htm

Korhonen, J., Honkasalo, A., & Seppälä, J. (2018). Circular economy: The concept and its limitations. Ecological Economics, 143, 37–46. https://doi.org/10.1016/j.ecolecon.2017.06.041

Neumüller, C., Kellner, F., Gupta, J. N. D., & Lasch, R. (2015). Integrating three-dimensional sustainability in distribution centre selection: the process analysis method-based analytic network process. International Journal of Production Research, 53(2), 409–434. https://www.tandfonline.com/doi/abs/10.1080/00207543.2014.939241

Deqiang, S., Zhijun, C., Hajduk-Stelmachowicz, M., Razaque Larik, A., & Zahid Rafique, M. (2021, November). The role of the global value chain in improving trade and the sustainable competitive advantage: Evidence from China’s manufacturing industry. Frontiers in Environmental Science, 9. https://www.frontiersin.org/articles/10.3389/fenvs.2021.779295/full.

Sureka, S., Shiva, S., Palkar, S., Jarwal, V., & Bhavsar, V. (2021, June). Sustainable supply chain management. SAMVAD: SIBM Pune Research Journal, 22, 36-40. http://samvad.sibmpune.edu.in/index.php/samvad/article/view/164045/113948 CC BY-3.0

Trucost, & GreenBiz. (January 31, 2018). Distribution of natural capital impacts among companies worldwide in 2016, by issue [Graph]. Statista. https://www.statista.com/statistics/597033/distribution-of-environmental-impacts-among-companies-worldwide-by-issue/

Villena,V. H., & Gioia, D.A.(2020). A More Sustainable Supply Chain. Harvard Business Review. https://hbr.org/2020/03/a-more-sustainable-supply-chain

Image Descriptions

Fig 8.1: Nutrients & Organic pollutants 33%; Greenhouse gases 31%; Water abstraction 18%; Heavy metal pollution 7%; Other 11% [Return to image].

Fig 8.4: Series of circles all moving clockwise. Inner circles (From smallest to largest) reuse, re-manufacturing, recycling, disposal. Outer circle (clockwise from top) product usage, product end-of-life, treatment, material end-of-life, nature, material/energy acquisition, material refinement, product manufacture. Around the outside at top and bottom: cost, time, energy [Return to image].

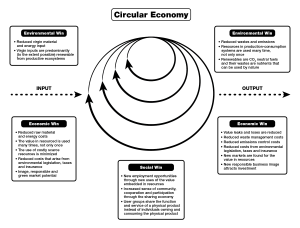

Fig 8.5: Four clockwise circles. Input with a an arrow pointing to the circles on the left and Output with an arrow pointing away from the circles on the right.

Input wins: Environmental (reduced virgin material and energy input, virgin inputs are predominantly (to the extent possible) renewable from productive ecosystems) and Economic (reduced ram material and energy costs, the value in resourced is used many times, not only once, the use of costly scarce resources is minimized, reduced costs that arise from environmental legislation, taxes and insurance, image, responsible and green market potential).

Output wins: Environmental (reduced wastes and emissions, resources in production-consumption systems are used many times, not only once, renewables are CO2 neutral fuels and their wastes are nutrients that can be used by nature) and Economic (value leaks and loses are reduced, reduced waste management costs, reduced emissions control costs, reduced costs from environmental legislation, taxes and insurance, new markets are found for the value in resources, new responsible business image attracts investment).

Social wins: new employment opportunities through new uses of the value embedded in resources, increased sense of community, cooperation and participation through the sharing economy, user groups share the function and service of a physical product instead of individuals owning and consuming the physical product [Return to image].

Fig 8.6: 3 sections to the diagram.

Centre: Renewables and Finite Materials arrows to parts manufacturer (renewable has up and down arrows), arrows to product manufacturer, service provider, consumer & user, collection, minimize systematic leakage and negative externalizes.

Left Side: Renewables flow management. Arrows from collection of middle diagram to Extraction of biochemical feedstock (post-harvest and post-consumer waste) arrows go back to consumer and then forward to anaerobic digestion, biogas, regeneration, farming/hunting/fishing/collection.

Right side: Stock management. Arrows from collection of middle diagram to maintain/prolong, resuse/redistribute, refurbish/remanufacture, recycle. [Return to image].

Fig 8.7: Examples of countries which adopted a national resource efficiency or circular economy strategy or action plan (non comprehensive list).

Already adopted a national circular economy strategy or action plan (A): France, Italy, Netherlands, Denmark, Portugal, Slovenia.

Currently finalizing a national circular economy strategy or action plan (B): Spain, Poland.

Already Adopted a national resource efficiency strategy or action plan (C): Germany, Austria, Ireland.

Adopted both resource efficiency and circular economy strategy or action plan (A) + (C): Scotland, Finland.

EEA-39 remaining countries: Bosnia & Herzegovina, Serbia, Albania, Turkey, Montenegro.

Outside EEA-39: Switzerland, Czech Republic, Slovakia, Croatia, Bulgaria, Hungary, Ukraine, England, Norway, Sweden, Baltic States, Russia [Return to image].

Fig 8.8: Wholesale waste and scrap: 3,023

Resuse of good 14,625

Domestic repairs 254,512

Industrial repairs 98,320

Waste collection 29,705

Materials recovery 55,454 [Return to image].

Fig 8.9: Various connections and relationships between a wide variety of factors such as lack of knowledge towards sustainability, supplier commitments, consumer orientations, lack of distribution and IT integration, financial constraints, insufficient government rules, lack of trust in the chain, lack of top management commitment to flexibility, lack of manufacturing flexibility, and inadequate communication. [Return to image].

Alternative Text-Based Activities

Assessing What You Already Know

Question 1:

Is the sustainable value chain focused on global issues? Check all that apply.

- human rights (Correct)

- global warming and melting ice caps (Correct)

- fair labour practices (Correct)

- Raw material (Incorrect)

- marine pollution (Correct)

- decreases of forest cover (Correct)

- plastic pollution (Correct)

- air pollution (Correct)

Feedback: The sustainable value chain focuses on global issues such as human rights, global warming and melting ice caps, fair labour practices, marine pollution, decreases of forest cover, plastic pollution, air pollution, etc. When companies consider goals related to minimizing the impact on the environment while benefiting the communities and the people, this means that this company addresses global issues and focuses on a Sustainable Value Chain.

Question 2:

What are the three dimensions of sustainability? Check all that apply.

- Social (Correct)

- Humanity (Incorrect)

- Ecological (Incorrect)

- Environmental (Correct)

- Economic (Correct)

Feedback: The main dimensions of suitability in the global value chain are environmental, economic, and social dimensions. Integration of three dimensions, economic, social, and environmental, can help companies achieve a long-term goal, and the sustainable supply chain is a crucial success factor for the future.

Question 3:

Sustainability is an opportunity for businesses?

- True (Correct)

- False (Incorrect)

Feedback: Sustainability is an opportunity for businesses, but it is hard to understand the global goals, trade, policies, and improving three main parts simultaneously: social, environmental, and economical. Moreover, the sustainable value chain is related to the core of the whole business, from the strategy to developing products and relationships.

Question 4:

On the basis of your previous experiences and knowledge, how would you define the term ‘circular economy’? Check all that apply.

- circular economy is a great practice to minimize the negative impact on the environment (Correct)

- circular economy helps company’s in inbound logistics (Incorrect)

- circular economy helps company’s in procurement (Incorrect)

Feedback: the circular economy is a great practice to minimize the negative impact on the environment and simultaneously stimulate businesses to find new opportunities. [Return to activity].

Check Your Understanding: Define the term Sustainable Value Chain and how it adds value in the global value chain

Question 1:

When a company addresses global issues and focuses on a Sustainable Value Chain, this means that

- companies consider expanding to the new market (Incorrect)

- companies consider goals related to minimizing the impact on the environment while benefiting

- the communities and the people – (Correct)

- companies would like to be socially responsible – (Incorrect)

Feedback: When companies consider goals related to minimizing the impact on the environment while benefiting the communities and the people, this means that this company addresses global issues and focuses on a Sustainable Value Chain. The sustainable value chain focuses on global issues.

Question 2:

Is the sustainable value chain focused on global issues? Check all that apply.

- human rights (Correct)

- global warming and melting ice caps (Correct)

- fair labour practices (Correct)

- Raw material (Incorrect)

- marine pollution (Correct)

- decreases of forest cover (Correct)

- Exploding data (Incorrect)

- plastic pollution (Correct)

- air pollution (Correct)

Feedback: The sustainable value chain focuses on global issues such as human rights, global warming and melting ice caps, fair labour practices, marine pollution, decreases of forest cover, plastic pollution, air pollution, etc. When companies consider goals related to minimizing the impact on the environment while benefiting the communities and the people, this means that this company addresses global issues and focuses on a Sustainable Value Chain.

Question 3:

What are the three dimensions of sustainability? Check all that apply.

- Social (Correct)

- Humanity (Incorrect)

- Ecological (Incorrect)

- Environmental (Correct)

- Economic (Correct)

Feedback: The main dimensions of suitability in the global value chain are environmental, economic, and social dimensions. Integration of three dimensions, economic, social, and environmental, can help companies achieve a long-term goal, and the sustainable supply chain is a crucial success factor for the future.

Question 4:

Companies should continuously identify …. Check all that apply.

- high-quality resources from the GVC (Correct)

- cost s in logistics activities – (Incorrect)

- discover ways of integrating internal and external carbon innovation resources – (Correct)

Feedback: The manufacturing subsidiaries’ capability to achieve a sustainable competitive advantage represents a significant asset when developing innovations. The findings reveal that a thorough evaluation of the company’s innovation resources to identify potential positions for the GVC is highly advisable. Therefore, companies should continuously identify high-quality resources from the GVC and discover ways of integrating internal and external carbon innovation resources to form innovation capability. Besides, companies should also analyze the cost issues of transforming the low-carbon innovation capability into a competitive advantage and evaluate the consistency of their low-carbon innovation strategy with the parent company.

Check Your Understanding: Explain the Concept of Circular Economy

Question 1:

According to the European Commission, how many euros can the manufacturing sector gain alone for the EU after the transition to the circular economy-type economy?

- 500 million euros (Incorrect)

- 600 billion euros – (Correct)

- 300 billion euros – (Incorrect)

Feedback: According to the European Commission, 600 billion euros can be gained in the manufacturing sector alone for the EU after the transition to the circular economy-type economy. Only the national Finland economy can earn 2.5 billion euros through a circular economy, and the global economy estimated benefits by 1000 billion US dollars annually (Korhonen, Honkasalo & Seppälä, 2018).

Question 2:

What is a Circular economy?

- It is fair labour practices (Incorrect)

- It is a great practice to minimize the positive impact on the environment and simultaneously stimulate businesses to find great opportunities (Incorrect)

- It is a great practice to minimize the negative impact on the environment and simultaneously stimulate businesses to find new opportunities (Correct)

Feedback: With the dawn of industrialization, the circular economy is a great practice to minimize the negative impact on the environment and simultaneously stimulate businesses to find new opportunities.

Question 3:

How can the circular economy be implied to reduce environmental effects? Check all that apply.

- remanufacturing, upgrading, and recycling (Correct)

- Repair and reuse (Correct)

- Constructing and using (Incorrect)

- upgrading, and recycling (Correct)

- refurbishment and disposal, (Correct)

- Destroying (Incorrect)

- cascading (Correct)

Feedback: A circular economy implies the following solutions to reduce adverse environmental effects: remanufacturing, repair, reuse, refurbishment, disposal, cascading, upgrading, and recycling.

Question 4:

The circular economy is the ………. potential for sustainable development because the CE contributes to sustainable development’s economic, social, and environmental dimensions

- win-win-won (Incorrect)

- win-won-win – (Incorrect)

- win-win-win – (Correct)

Feedback: The circular economy is the win-win-win potential for sustainable development because the CE contributes to sustainable development’s economic, social, and environmental dimensions.

Check Your Understanding: Describe various initiatives taken by organizations to make their supply chains sustainable

Question 1:

Drag and Drop recommendations in correct Category

| Indicator | Recommendations |

|---|---|

| Material Value Added-Supply Chain (MVA-SC) | Redesign the production process, for example, by applying process intensification and/or process integration. |

| Energy Cost-Supply Chain (EC-SC) | Invest in equipment and vehicles that are more efficient, as well as investing in continuous heat integration |

| Total Inventory Level Cost (TILC) Entity Inventory Level Cost (EILC) |

Decrease the level of production and demand uncertainty. The production uncertainty can be reduced by implementing more robust production processes. Demand uncertainty can be decreased by identifying a significant buffer near the end customer to protect the supply chain from market uncertainties or by applying a production leveling technique (“heijuka”). |

| Backorder Cost (BC) | Improve supply chain coordination and inventory management policies. |

| Lead Time Factor (LTF) Operational Lead Time Factor (OLTF) |

Ideally, all activities should be located at the same place near the end customer. This is often not possible, so the recommendation is to find facilities that share material flows and locate them as close as possible. Using “just in time” methods such as pull systems or process synchronization also shortens the lead time. |

| Inventory Turnover (IT) | Reduce the inventory by gradually ensuring not compromising the service level or reducing the batches’ size and increasing the pick-up frequency. |

| Volume Flow (VF) | Redirect the flow of material to another path with a lower workload, or boost the work capacity acquiring newer and more effective equipment. |

| Ok-Parts (OK-P) | Implement failure prevention techniques (“poka yoke”) to reduce scrap and rework in every facility’s production processes. |

| Service Level Quantity Factor (SLQF) and Service Levels Time Factor (SLTF) | Improve the information sharing between the supply chain members to know the capacity constraints and each supplier’s inventory management. According to the collected information, find out how to deliver the required orders in the proper quantity and time. |

| Overall Thoughput Effectiveness (OTE-SC) | Implement kaizen workshops to decrease the production uncertainty (technical, organizational and quality losses, and changeover times). |

| Variability Lead Time (VLT) | Homogenize all the processes of the value stream to gain stability and ensure consistent results over time. |

| Bullwhip Effect (BE) | Adopt a centralized multi-echelon inventory control system since it presents a superior performance over independently operating site-based inventory. |

| Carbon Emissions (CE) | Implement more energy-efficient equipment, vehicles and facilities; and/or optimize the supply chain operations. |

| Waste Factor (WF) | Reengineer the production process to be more efficient and promote recycling policies. |

| Sustainable Energy (SE) | Improve energy efficiency and invest in renewable and sustainable energy sources. |

| Labour Equity (LE) | Improve the lowest salary and/or reduce the highest salary—decrease salary disparity. |

| Fatal Accident Rate (FAR) | Improve labor conditions by implementing robust security policies and provide training to the employees. |

| Corruption (C) | Organize workshops to raise awareness among managers and promote transparent communication of information. |

Question 2:

Can managers potentially improve indicators and simultaneously make their supply chains more sustainable?

- True (Correct)

- False (Incorrect)

Feedback: Managers can potentially improve indicators and simultaneously make their supply chains more sustainable.

Question 3:

Is it easy to adapt to include sustainability aspects in lean management?

- Yes (Correct)

- No – (Incorrect)

Feedback: Lean management has proven to be a handy and innovative tool to promote continuous improvement and is easily adaptable to include sustainability aspects. Due to the ongoing interest and need to implement corporate environmental and social policies, combining lean management and sustainability has become more popular. An increasing number of studies have proven clear positive impacts (economic, environmental and social) on the supply chain performance when lean is linked to sustainability.

Question 4:

Check all best practices for multinational corporations for promoting environmental and social responsibility. Check all that apply.

- Establish long-term sustainable goals (Correct)

- First-tier suppliers must establish their own long-term sustainability goals (Correct)

- Lower-tier suppliers should not be included in the global corporate sustainability strategy – (Incorrect)

- An employee irresponsible for promoting sustainability programs to lower and first-tier suppliers – (Incorrect)

- First-tier suppliers have to be monthly assessed by asking about their safety, health, labour, and environmental practices in their workplace – (Incorrect)

- Conduct a survey about the sustainability of the supply chain to comply with multinational corporations’ requirements within the company- (Correct)

- Training first-tier suppliers to comply with their standards as well as providing incentives for using sustainability practices (Correct)

Feedback: They have to establish long-term sustainable goals (Villena & Gioia, 2020).

First-tier suppliers must establish their own long-term sustainability goals. Lower-tier suppliers should be included in the global corporate sustainability strategy An employee responsible for promoting sustainability programs to lower and first-tier suppliers. First-tier suppliers have to be annually assessed by asking about their safety, health, labour, and environmental practices in their workplace. Conduct a survey about the sustainability of the supply chain to comply with multinational corporations’ requirements within the company. There are many indicators and critical performance within the company to monitor supplier sustainability annually. Training first-tier suppliers to comply with their standards as well as providing incentives for using sustainability practices. The training and incentives led suppliers to increase awareness and make significant changes within the industry (Villena & Gioia, 2020).

Check Your Understanding: Learn the main dimensions of sustainability in the global value chain

Question 1:

What are the three dimensions of sustainability? Check all that apply.

- Social (Correct)

- Humanity (Incorrect)

- Ecological (Incorrect)

- Environmental (Correct)

- Economic (Correct)

Feedback: The main dimensions of suitability in the global value chain are environmental, economic, and social dimensions. Integration of three dimensions, economic, social, and environmental, can help companies achieve a long-term goal, and the sustainable supply chain is a crucial success factor for the future.

Question 2:

For achieving a sustainable value chain and development, companies have to integrate and balance economic, social and environmental dimensions within their companies.

- True – (Correct)

- False – (Incorrect)

Feedback: For achieving a sustainable value chain and development, companies have to integrate and balance economic, social and environmental dimensions within their companies (Neumüller, Kellner, Gupta, & Lasch, 2015). Decision-makers within organizations have to focus simultaneously on economic effects and consider the impact on the social and environmental aspects. Companies can compromise customer satisfaction but gain a tremendous impact on society and the environment. [Return to activity].

Check Your Understanding: Identify key sustainability challenges in value chains and recommend solutions

Question 1:

Drag and Drop the components in correct Category

| Challenges | Definition |

|---|---|

| Autonomous challenges | The identified challenges that include weak driving power and dependence are categorized under the first quadrant. In this study, there are no autonomous challenges from our identified potential challenges. |

| Dependent challenges | Identified challenges that have weak guidance but strong dependence are categorized under the second quadrant. From the obtained list, challenges such as ‘lack of top management commitment toward flexibility in value chain (B11)’, ‘lack of manufacturing flexibility in the value chain (B12) and ‘Inadequate communication among the suppliers in the value chain (B13)’ are posed as dependent challenges because they represent strong dependence but relatively weak driving power. |

| Linkage challenges | The identified challenges that have high dependence and high driving power are categorized under the third quadrant. In this study, linkage challenges among our identified potential challenges are ‘insufficient government rules toward sustainable initiatives (B6)’, ‘financial constraints toward sustainable initiatives (B7)’, ‘capacity constraints in value chain flexibility (B8)’, ‘lack of trust in the value chain (B9)’ and ‘inadequate information sharing in value chain (B10). |

| Independent challenges | Identified challenges that have strong driving power but weak dependence are categorized under the fourth quadrant. In this study, challenges such as ‘lack of consumer orientation toward sustainability in value chain (B1)’, ‘lack of distribution flexibility in the value chain (B2)’, ‘lack of supplier commitment toward sustainable products (B3)’, ‘lack of knowledge toward sustainability in value chain (B4)’, and ‘lack of IT integration in value chain (B5)’ are classified as independent challenges because they reflect strong driving power but weak dependence. The construct for the dependence and driving power analysis. |

Question 2:

Key sustainable challenges in the value chain. Check all that apply.

- Lack of consumer orientation toward sustainability in value chain (Correct)

- Lack of distribution flexibility in the value chain (Correct)

- Lack of supplier commitment towards sustainable products (Correct)

- Lack of knowledge towards sustainability in value chain (Correct)

- Sufficient government rules towards sustainable initiatives – (Incorrect)

- Financial constraints towards sustainable initiatives (Correct)

- Adequate Information sharing in value chain- (Incorrect)

- Capacity opportunities in value chain flexibility – (Incorrect)

- Lack of top management commitment towards flexibility in value chain (Correct)

- Lack of manufacturing flexibility in the value chain (Correct)

- Adequate communication among the suppliers in the value chain- (Incorrect)

Feedback:

| N0 | Challenges |

|---|---|

| 1 | Lack of consumer orientation toward sustainability in value chain |

| 2 | Lack of distribution flexibility in the value chain |

| 3 | Lack of supplier commitment towards sustainable products |

| 4 | Lack of knowledge towards sustainability in value chain |

| 5 | Lack of IT integration in value chain |

| 6 | Insufficient government rules towards sustainable initiatives |

| 7 | Financial constraints towards sustainable initiatives |

| 8 | Capacity constraints in value chain flexibility |

| 9 | Lack of trust in the value chain |

| 10 | Inadequate Information sharing in value chain |

| 11 | Lack of top management commitment towards flexibility in value chain |

| 12 | Lack of manufacturing flexibility in the value chain |

| 13 | Inadequate communication among the suppliers in the value chain |

Question 3:

Is it unnecessary to communicate the advantages associated with the use of natural resources, of working in conditions of minimum risk to the health of citizens, of no exploitation of people?

- True- (Incorrect)

- False – (Correct)

Feedback: It is difficult to change this principle, which is the basis of doing business. However, it is necessary to communicate the advantages associated with the use of natural resources, of working in conditions of minimum risk to the health of citizens, of no exploitation of people. In fact, where the organization and the worker have the same objective, the benefits translate directly into the well-being of the company and the ability to generate income for the entire community. Inadequate communication among the suppliers in the value chain deriving by information asymmetries would lead to a loss of value for all the shareholders.

Question 4:

Businesses that incorporate sustainability principles into their strategies and practices can be competitive in the local market by fostering the development of a local supply chain.

- True- (Correct)

- False – (Incorrect)

Feedback: Businesses that incorporate sustainability principles into their strategies and practices can be competitive in the local market by fostering the development of a local supply chain. This process includes the creation of smart networks in which companies share their resources in order to be competitive in a global market. The results show that inadequate communication among the suppliers in the value chain has among the lowest driving power. [Return to activity].

“causing, or made in a way that causes, little or no damage to the environment and therefore able to continue for a long time” (Cambridge dictionary, 2022)