5.4 Demand Planning, Inventory Management & Control

Learning Objectives

3. Discuss the importance of demand planning and Inventory Management in value chain.

4. Describe inventory control systems and strategies used for ensuring optimal inventory levels.

Demand Planning and Inventory Management

Imagine you are a manager who has done everything in their power to help develop and promote a product—and it’s selling well. But now the company is running short of product because the demand forecasts were too low. This is the scenario Nintendo faced when the Wii first came out. The same happened with IBM when it launched the popular ThinkPad laptop in 1992. Not only is the product shortage that adversely affects profitably of a company, but it affects all the stakeholders.

Thus, demand planning is essential for a company to manage their inventories well. Demand planning is the process of estimating how much good customers will buy from you. If you’re a producer, demand planning will affect not only the amount of finished goods you have to produce but also the raw materials you must purchase to make them. It will also affect the production scheduling or the resources, events, and processes needed to create an offering. For example, if demand is heavy, you might need your staff members to work overtime. Closely related to demand forecasting are lead times. A product’s lead time is the amount of time it takes for a customer to receive a good or service once it’s been ordered. Therefore, lead times also have to be considered when a company is forecasting demand.

Forecasting decisions must be made more frequently — sometimes daily. Nowadays, companies are also moving to demand forecasts for multiple work shifts during a day. One way for you to predict the demand for your product is to look at your company’s past sales. This is what most companies do. But they don’t stop here. Why? Because changes in many factors — the availability of materials to produce a product and their prices, global competition, oil prices (which affect shipping costs), the economy, and even the weather — can change the picture.

In addition to looking at the sales histories of their firms, value chain managers also consult with other managers when they are generating demand forecasts. Firms also look to their value chain partners to help with their demand planning. Collaborative planning, forecasting, and replenishment (CPFR) is a technique value chain partners use to share information and coordinate their operations (University of Minnesota, 2015).

Did You Know?

Walmart has developed a Web-based CPFR system called Retail Link. Retailers can log into Retail Link to see how well their products are selling at various Walmart stores, how soon more products need to be shipped to the company, how any promotions being run affect the profitability of their products, and so forth. Because different companies often use different information technology systems and software, Web-based tools like Retail Link are becoming a popular way for value chain partners to interface with one another.

The trend is clearly toward more shared information, or what businesspeople refer to as value chain visibility. After all, it makes sense that a supplier will be more reliable and in a better position to add value to your products if they know what your sales, operations, and marketing plans are — and what your customers want. By sharing more than just basic transaction information, companies can see how well operations are proceeding, how products are flowing through the chain, how well the partners are performing and cooperating the extent to which value is being built into the product. Demand-planning software can also be used to create more accurate demand forecasts.

Litehouse Foods, a salad dressing manufacturer, improved its forecasts dramatically by using demand-planning software. Initially the company used a traditional sales database and spreadsheets to do the work. “It was all pretty much manual calculations. We had no engine to do the heavy lifting for us,” says John Shaw, the company’s Information Technology director. Yet, in a short time, the company \ reduced its inventory by about one-third while still meeting its customers’ needs (Casper, 2008).

Video: Inventory Planner Overview | Demand Planning | Sales Forecasting | Replenish Stock and Inventory (3:43)

Watch this video to know more about the benefits of Demand and Inventory Planner:

Media 5.4. Inventory Planner Overview | Demand Planning | Sales Forecasting | Replenish Stock and Inventory[Video]. Inventory Planner. (URL: https://youtu.be/pmkYiKt9QTI)

Companies are also moving towards Lean Manufacturing techniques to enhance visibility through out the value chain network. One such technique is Value Stream Mapping or Material and Information Flow Mapping (Manos, 2006) . “It is a lean -management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer (Wikipedia, 2021).”

As per Purdue University,

The process of creating a value stream map takes all the necessary people, processes, information and inventory, and displays them in a flowchart format. By visualizing all elements that go into creating a product or service, organizations can apply Lean Principles to reduce waste in specific areas of their processes.

To gain more information about the concept of ‘Value Stream Mapping’, read the article What is Value Stream Mapping?

Inventory Management and Control

Inventory management is one of the essential business processes related to purchases, sales and logistic activities. It is concerned with the control of stocks throughout the value chain. The essence of inventory management is to augment business operations to ensure the adequate flow of goods, products, and services is in place (Chalotra, 2015). In this context, ‘inventory’ is the aggregate list of items, several goods in stock or stock of the product an organization produces for sale and the components that make the sale. ‘Stock’ consists of a wide range of goods or materials – stationery, office equipment, plant, machinery, consumables, etc., available for use or sale.

Inventory control sits at the data level, where the day-to-day business is organized. Activities here are data-driven and primarily concerned with short-term planning and recording events. Inventory control is concerned with maintaining the correct stock level and recording its movement.

According to Kotler, Roberto & Lee (2002), inventory management referred to all the activities involved in developing and managing the inventory levels of raw materials, semi-finished materials and finished goods so that adequate supplies are available and the costs of over or under stocks are low. Inventories are essential for keeping the production wheels moving, the market going, and the distribution system intact.

Did You Know?

When on the World Trade Center attack occurred, many Americans rushed to the store to buy batteries, flashlights, American flags, canned goods, and other products if the emergency signaled a much bigger attack. Target sold many items and could not replenish them for several days, partly because its inventory tracking system only counted up what was needed at the end of the day. On the other hand, Walmart counted what was required every five minutes. Before the end of the day, Walmart had purchased enough American flags, for example, to meet demand and, in doing so, completely locked up all their vendors’ flags. Meanwhile, Target was out of flags and out of luck — there were no more to be had.

Video: Types of Inventory : The 4 Different Buckets to know. (2:30)

Watch this video for an introduction to different types of inventories.

Media 5.5. Types of Inventory : The 4 Different Buckets to Know [Video]. LeanVlog. (URL: https://www.youtube.com/watch?v=TU2OniIvVmw)

To help avoid stock outs, most companies keep a certain amount of safety stock on hand. Safety stock is backup inventory that serves as a buffer in case the demand for a product surges or its supply drops off for some reason. However, maintaining too much inventory ties up money that could be spent in other ways — perhaps on marketing promotions. Inventory also has to be insured, and in some cases, taxes must be paid on it. Products in inventory can also become obsolete, deteriorate, spoil, or “shrink.” Shrinkage is a term used to describe a reduction or loss in inventory due to shoplifting, employee theft, paperwork errors, or supplier fraud (Hudson, 2020).

Do You Know - Why Companies Hold Inventories?

Many reasons exist for keeping stocks of inventory. Some of the most common include:

- Manufacturers often build up inventories throughout the year because of seasonal demand.

- An example is a chocolate manufacturer. To handle high demand for chocolate during Christmas, they begin building inventory in late spring to have enough on hand for orders in November and December.

- At the same time, a manufacturer may carry large amounts of inventory if they have some uncertainty or risk in their supply base. If there are chances of shortages, work stoppages, poor quality or late deliveries from suppliers, more stock may be carried.

- Firms may be tempted by extra discounts often provided by purchasing large order sizes. Perhaps they may want to minimize transportation costs. There may also be some worry about future price increases that can cause organizations to build up their inventories.

- Retailers carry inventory to ensure that they do not run out of what they anticipate their customers may want. Distributors and retailers may try to balance the cost of keeping extensive inventories on hand and providing excellent customer service with few or no disappointed customers. However, it is often a challenge to anticipate exact customer behaviour.

- It is a challenge to synchronize the incoming flow of materials and goods to meet production schedules and ship to customers as promised. As a result, inventory may be stored at many locations along the supply chain. This causes extra costs and inefficiencies for each organization.

Inventory Management Techniques

Inventory management techniques are extremely important as they result in success and cost reduction of a company. In this section, different techniques of inventory management are discussed.

Economic Order Quantity

- Only one product involved

- Annual demand requirements are known

- Demand is spread evenly throughout the year so that the demand rate is reasonably constant

- Lead time does not vary

- Each order is received in a single delivery

- There are no quantity discounts

Vendor Managed Inventory (VMI)

The Vendor Managed Inventory model of inventory management allows collaboration between vendors and the company.

According to Oluwaseyi J, Onifade & F. (2017),

VMI enables the vendor in a vendor/customer relationship to plan, monitor, and control inventory for their customers. The vendor manages the inventory within specific levels previously agreed upon, while the customer concentrates on improving demand accuracy. The customer organization relinquishes the order-making responsibilities in exchange for timely inventory replenishment, ultimately increasing overall capacity planning and institutional efficiency.

Video: Vendor Managed Inventory from Mars Electric (1:10)

Watch this video to see how a vendor knows as Mars electric is helping their consumers.

Media 5.6. Vendor Managed Inventory from Mars Electric [Video]. Mars Electric. (URL: https://youtu.be/gmvH4boZX5c)

Just in Time Technique

Just in time (JIT) is a production strategy striving to improve business’ return on investment by reducing in-process inventory and associated carrying costs. To meet JIT objectives, the process relies on signals or Kanban between different points in the process. Kanban are usually “tickets” but can be simple visual signals, like the presence or absence of a part on a shelf. Implemented correctly, JIT focuses on continuous improvement and can also result in improved return on investment, quality and efficiency. To achieve continuous improvement, key areas of focus are:

- flow

- employee involvement

- quality

Did You Know?

Dell is an example of a company that utilizes a just-in-time inventory system that’s vendor-managed. Dell carries very few parts. Instead, its suppliers accept them. They are located in small warehouses near Dell’s assembly plants worldwide and provide Dell with components “just-in-time” for them to be assembled (Kumar & Craig, 2007 ). Dell’s inventory and production system allows customers to get their computers built precisely to their specifications; a production process called mass customization. This helps keep Dell’s inventory levels low. Instead of a huge inventory of expensive, already-assembled computers consumers may or may not buy, Dell simply has the parts on hand, which can be configured or reconfigured should consumers’ preferences change. As a result, Dell can more quickly return the pieces to its suppliers if, at some point, it redesigns its computers to match better what its customers want. And by keeping track of its customers and what they are ordering, Dell has a better idea of what they might order in the future and the types of inventory it should hold. Because mass customization lets buyers “have it their way,” it also adds value to products, for which many customers are willing to pay.

ABC Based Costing Technique

The ABC analysis is an inventory categorization technique often used in material management wherein accuracy and control decrease from A to C. It is also known as “Selective Inventory Control” (Saylor Academy, n.d.). Fellows & Rottger (2005) agree that having inventory in your store has an added advantage for the organization since customers will be satisfied instantly, leading to improved performance ratings. ABC Analysis is based on Pareto (80/20) Principle that indicates that 80% of value addition is from 20% inventories companies hold.

This technique categorizes goods based on their unit value and divide them in 3 categories:

- A, items with high unit value, very tight control and accurate records,

- C, with relatively small unit value, large presence in warehouse, simplest control and minimal records, and

- B, which lies between category A & C and has moderate unit value, less tightly controlled and good records.

Where A needs tighter control because of its high value addition, B cannot be ignored as these items have a potential to convert into A items.

Table 5.1

| PARTICULARS | A ITEMS | B ITEMS | C ITEMS |

|---|---|---|---|

| CONTROL | Tight | Moderate | Loose |

| REQUIREMENT | Exact Close | Exact Some | Estimated |

| CHECK | Regular | Some | Little/No |

| EXPENDITURE | Industrial | Individual | Group/None |

| POSTING | Low | Medium | n/a |

| SAFETY STOCK | High | n/a | Rare |

Note. Activity Based Costing. From Oluwaseyo, Onifade & F. (2017). CC BY-NC-ND 3.0.

Table 5.2 outlines how application of these and a few other techniques improves company’s performance:

Table 5.2

| NO. | INVENTORY MANAGEMENT TECHNIQUES | HOW IMPROVED PERFORMANCE WILL BE ACHIEVED |

|---|---|---|

| I | Economic Order Quantity | Ability to know how much and when to replenish inventory |

| II | Marginal Analysis | Reduce loss for inventory that is perishable within a short period of time by ensuring they are ordered at the right time. |

| III | Just-in-Time | Ordering inventory when they are required thus reducing storage/holding costs |

| IV | Simulation | Capability of laying out inventory management plans for the organization |

| V | Order Batching | Minimizing on unnecessary costs on transport |

| VI | Vendor Managed Inventory | Improving on inventory management systems by engaging outsourced suppliers to management inventory monitoring and replenishment. |

| VII | ABC Analysis | The organization is able to account for each inventory according to its classification and this can be achieved through the Pareto analysis. |

Note. Inventory Management Techniques. From Oluwaseyi, Onifade & F. (2017). CC BY-NC-ND 3.0.

Inventory Tracking

Some companies, including Walmart, are beginning to experiment with new technologies such as electronic product codes to manage their inventories better. An electronic product code (EPC) is similar to a barcode, only better because its number is truly unique. You have probably watched a checkout person scan a barcode off of a product identical to the one you wanted to buy—perhaps a pack of gum—because the barcode on your product was missing or wouldn’t scan. Electronic product codes make it possible to distinguish between two identical packs of gum. In addition, the codes contain information about when the packs of gum were manufactured, where they were shipped from, and where they were going. Knowing the difference between “seemingly” identical products can help companies monitor their expiration dates if they are recalled for quality or safety reasons. EPC technology can also combat “fake” products or knockoffs in the marketplace.

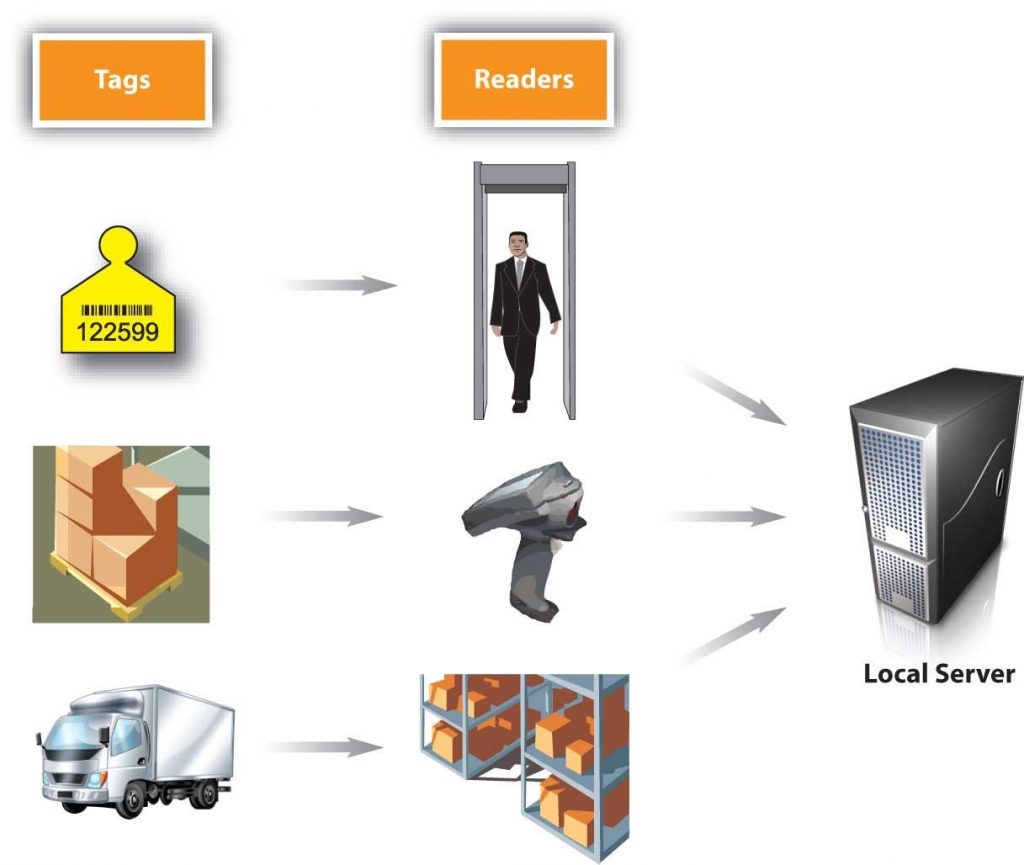

Electronic product codes are stored on radio-frequency identification (RFID) tags. A radio-frequency identification (RFID) tag emits radio signals that can record and track a shipment as it comes in and out of a facility. If you have unlocked your car door remotely, microchipped your dog, or waved a tollway tag at a checkpoint, you have used RFID technology. Because each RFID tag can cost anywhere from $0.50 to $50 each, they are generally used to track larger shipments, such as cases and pallets of goods rather than individual items.

Video: The Basic of RFID and EPC (4:14)

Watch this video to know the Basics of RFID and EPC Technology.

https://youtu.be/k-w6ZYIo37E

Media 5.7. The Basic of RFID and EPC [Video]. erwinofm. (URL: https://youtu.be/k-w6ZYIo37E)

Some consumer groups worry that RFID tags and electronic product codes could be used to track their consumption patterns or for the wrong purposes. But keep in mind that the codes and tags are designed to work only within short ranges like your car-door remote. (You know that if you try to unlock your car from a mile away using such a device, it won’t work.)

See Figure 5.6 to get an idea of how RFID tags work.

How RFID Tagging Works

Note. How RFID Tagging Works [Image]. From Principles of Marketing, 2015, CC BY-NC-SA 4.0. [Image description].

Proponents of electronic product codes and RFID tags believe they can save consumers and companies time and money. These people believe consumers benefit because the information embedded in the codes and tags helps prevent stock outs and out-of-date products remaining on store shelves. In addition, the technology doesn’t require cashiers to scan barcodes item by item. Instead, an electronic product reader can automatically tally up the entire contents of a shopping cart—much like a wireless network can detect your computer within seconds. As a customer, wouldn’t that add value to your shopping experience? (University of Minnesota, 2015).

Check Your Understanding

Answer the question(s) below to see how well you understand the topics covered above. You can retake it an unlimited number of times.

Use this quiz to check your understanding and decide whether to (1) study the previous section further or (2) move on to the next section.

Check Your Understanding: Demand Planning, Inventory Management & Control

Interactive activity unavailable in this format

Text-based alternative. to interactive activity available in Chapter 5.7

Media Attributions and References

erwinofm. (n.d.). The Basic of RFID and EPC [Video]. YouTube. https://youtu.be/k-w6ZYIo37E.

Inventory Planner. (2022, Sept 15). Inventory planner overview | Demand planning | Sales forecasting | Replenish stock and inventory [Video]. YouTube. https://youtu.be/pmkYiKt9QTI.

LeanVlog. (n.d.). Types of Inventory : The 4 different buckets to know [Video]. YouTube. https://www.youtube.com/watch?v=TU2OniIvVmw.

Mars Electric, (2019, November 19). Vendor managed inventory from Mars Electric [Video]. YouTube. https://youtu.be/gmvH4boZX5c.

University of Minnesota. (2015, October 17). Principles of marketing. University of Minnesota Libraries Publishing Edition. https://doi.org/10.24926/8668.1901. CC BY-NC-SA 4.0.

The process to forecast consumer's demand in future.

The time gap between placing an ordering and receiving it.

Making a company's operations visible to all stakeholders.

Managing the stock of goods in warehouse

Aggregate list of items, several goods in stock or stock of the product an organization produces for sale and the components that make the sale.

The goods or materials such as stationery, office equipment, plant, machinery, consumables, etc., available for use or sale.

work in progress

Shortages or availability of less than required Inventory.

backup inventory