2.3 Inbound and Outbound Logistics

Learning Objective

2. Explain the terms Inbound and Outbound Logistics and their components.

Inbound and Outbound Logistics – Introduction

Figure 2.3

Inbound Logistics

Note. Inbound Logistics. From Elevate, 2018. Used under the Unsplash License.

Inbound Logistics refers to anything that is coming inside a company. For a furniture manufacturer, inbound logistics would mean managing the arrival of raw materials or semi-finished products such as wood, paint, nuts, screws, bolts etc. For an Amazon Fulfillment centre, on the other hand, inbound logistics would mean managing receiving, quality check, storage etc. of finished goods.

“Inbound logistics is one of the primary processes of logistics concentrating on purchasing and arranging the inbound movement of materials, parts, or unfinished inventory from suppliers to manufacturing or assembly plants, warehouses, or retail stores (Wikipedia, 2019)”.

According to Minner,

Inbound Logistics comprises all activities that secure the supply for manufacturing and assembly or sales. These activities range from order placement and order allocation between suppliers to a chosen delivery and transportation concept for the receipt and storage or immediate use of the materials.

Video: Inbound Logistics Solutions – Machine Vision & Barcode Reading for Distribution & Fulfillment (4:20)

Watch this video to understand the role of technology in Inbound Logistics.

Media 2.2. Inbound Logistics Solutions – Machine Vision & Barcode Reading for Distribution & Fulfillment [Video]. CognexTV. (URL: https://youtu.be/Maz17CvqJa4)

A manager in charge of inbound logistics manages everything related to the incoming flow of resources that the company needs to produce its goods or services. These activities will include managing supplier relationships, accessing raw materials, negotiating materials pricing, and arranging quicker delivery.

Check Your Understanding

Answer the question(s) below to see how well you understand the topics covered above. You can retake it an unlimited number of times.

Use this quiz to check your understanding and decide whether to (1) study the previous section further or (2) move on to the next section.

Check Your Understanding: Inbound Logistics

Interactive activity unavailable in this format

Text-based alternative to interactive activity available in Chapter 2.6.

Outbound Logistics

Figure 2.4

Outbound Logistics

Note. Forklift in Warehouse. From Nebov, J. 2021. Used under the Unsplash License.

Outbound Logistics refers to anything that is going outside of a company. Outbound processes are vital for companies as they connect them directly with their customers in value chain (Klumpp and Heragu, 2019).” For instance, for a furniture manufacturer outbound logistics would mean managing delivery of finished furniture such as sofa sets, beds, chairs etc., to furniture retailers. For Furniture retailers, on the other hand, outbound logistics would comprise managing the distribution of finished goods to consumers on time and in good condition.

Council of Supply Chain Management Professionals defines Outbound Logistics as “the process related to the movement and storage of products from the end of the production line to the end consumer”.

A manager working in outbound logistics will be focused on two issues: storage and transportation. They will use warehousing techniques to keep the finished goods safe and accessible. Since the products may need to be moved out to a customer at any moment, proper organization is crucial. Having as little product stored as possible can be advantageous since stored products are not making money, so the outbound logistics manager often has to balance company cost savings with consumer demand. The transportation function is by far the most complex part of outbound logistics. Without transport, there simply is no logistics. For that reason, it’s critical to be able to move the product from one location to another in the fastest, most cost-effective, and efficient way possible. Since transportation involves fluctuations, factors such as delays and changes in fuel costs need to be taken into account to cover all possible scenarios that might jeopardize the efficient movement of goods.

Video: Discover the World of Outbound Logistics with Tata Steel (2:54)

Watch this video to understand how Tata Steel manages their Outbound Operations.

Media 2.3. Discover the World of Outbound Logistics within Tata Steel [Video]. Tata Steel Jobs. (URL: https://youtu.be/5RH9xMAANf8)

Check Your Understanding

Answer the question(s) below to see how well you understand the topics covered above. You can retake it an unlimited number of times.

Use this quiz to check your understanding and decide whether to (1) study the previous section further or (2) move on to the next section.

Check Your Understanding: Outbound Logistics

Interactive activity unavailable in this format

Interactive activity unavailable in this format

Text-based alternative to interactive activity available in Chapter 2.6.

Inbound and Outbound Logistics, taken together, links Suppliers in the upstream to consumers in the downstream. However, Inbound logistics focuses on the Supply-side whereas Outbound Logistics focuses on the demand side of the supply-demand equation. So, to ensure the operational success of any business, it is essential to focus equally on inbound and outbound operations. As per Jejani et al., 2019:

Outbound and Inbound logistics, both activities, play complementary roles to the success of the logistics function of the company while one guarantees that your management has all the supplies it needs to keep the production line upend running, the other connects your products to the final buyer. Therefore, both parts should be carefully planned and executed so that your supply chain and logistic can be as effective as possible and you are able to meet your customers’ expectations and requirements with ease.

Inbound and Outbound Logistics – Components

Before delving deeper into components of Inbound and Outbound Logistics, let’s look at the term logistics and it’s importance once again.

Video: Why is Logistics Management Important? (0:40)

Watch this video that provides an overview of the importance of Logistics Management.

Media 2.4. Why is Logistics Management Important? [Video]. PLS Logistics Services. (URL: https://youtu.be/eF1aYwDmppM)

The Components of Inbound and Outbound Logistics vary from Industry to Industry. “How a company approaches inbound logistics varies depending on incoming goods, the industry and the buyer-seller relationship (Jenkins, 2020) .”

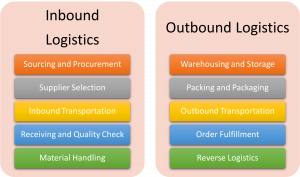

In this part of the chapter, we will focus on Inbound and Outbound Logistics activities. Figure 2.5 gives a quick view of these activities:

Components of Inbound and Outbound Logistics

Note. Components of Inbound and Outbound Logistics. [Image description].

Inbound Logistics Components:

As we know, Inbound Logistics works closely on the market’s supply side. Therefore, it would include activities related to suppliers and receiving of materials coming inside a company. Let’s discuss these activities in detail.

- Sourcing and Procurement: This is the first activity a company does when it decides to trade globally. They start exploring suppliers in international markets who can provide them with required materials within desired time frame and agree to work on specified terms and conditions. In simple words, they decide to purchase the materials, which is called Sourcing or Procuring in Logistics terminology . “Procurement includes the activities involved in establishing fundamental requirements; sourcing activities, such as market research and vendor evaluation; and negotiation of contracts (Bhargove, 2018 ).”

- Supplier Selection: This is another significant activity as it decides the quality of your outbound operations and success of your business in the long run. Suppliers are companies or individuals who provide you with the required material at the required time. In case a company ends up selecting a wrong supplier, it has financial implications and can impact the operational success of a business. Therefore, choosing suitable suppliers is crucial because it directly affects cost reduction, profitability, and company flexibility (Ting & Cho. 2008, p. 116-117). In some cases, it is also considered as a part of procurement.

- Inbound Transportation: Inbound Transportation relates to material movement from suppliers to the manufacturing unit. It is one of a company’s significant decisions as it consumes much of its cost. The success of other activities depends upon whether the material has been received on time and in good condition. Therefore, a highly responsive and economical transportation system can be considered a strong pillar for any business to fulfill consumer demands at a reduced cost. Conversely, its absence can lead to increased costs of goods and services (Ogar, 2017).

- Receiving and Quality Check: After inbound transportation comes receiving and quality check of the received material. During receiving, goods are unpacked, checked for any damages or quality and quantity issues, entered into the inventory system and staged for movement to the storage area. The aim here is ensure that received products comply with ordering documentation and are not damaged during shipping (LINCS, 2017, p.38).

- Material Handling: Once company receives goods, it’s vital to handle them properly. “Material Handling is the function of moving the right material to the right place, at the right time, in the right amount, in sequence, and in the right position or condition to minimize production cost (Stephens, 2019).” It includes other sub activities as well such as receiving, incoming quality check, warehousing and production scheduling.

Outbound Logistics Components

Outbound Logistics work closely on the demand side of the market. It would include order processing, Storage Management, Packing, Distribution and Reverse Logistics. Let’s discuss these activities in detail.

- Warehousing and Storage: Once a company receives goods, these are stored in the warehouses to fulfill consumer demand. A company needs to decide the number of goods to be stored as when goods stay in warehouses for a more extended period; additional costs are incurred. In warehouses, there is an overlap of inbound and outbound logistics. Where later specifically focus on sending goods directly to consumers or retail stores, the former works towards product acquisition (Jenkins, 2020).

- Picking and Packaging: When a consumer places order, warehouse associates pick the products ordered and forward them to the packaging department. The packaging associates make sure that goods are appropriately packaged within the transportation requirements of labelling and kitting, ensuring the safety of goods while in transit. For instance, fragile goods are packed using bubble wrapping so that these are not damaged during transportation and are labelled effectively for proper handling.

- Outbound Transportation: The modes of transportation and other requirements remain the same for inbound and outbound transportation. The only difference is that in inbound transportation goods arrive at a facility and in outbound transportation goods move out of a facility. As Dao et. al., 2018 states, “Inbound Logistics includes all aspects of material sourcing, material purchasing, transporting to factories. Meanwhile, outbound logistics handles the rest of the process such as transportation of the finished goods to warehouses or distribution centers, then from warehouses or distribution centers to customers.”

- Order Fulfillment: Delivering products at the right time and in proper condition to the consumer is all about order fulfillment. Companies can have their fleet of trucks and drivers or get services from courier companies like UPS and FedEx to fulfill consumer orders. In some instances, order fulfillment is a process where inbound and outbound logistics intersect. A complete order fulfillment lifecycle starts with strategic sourcing and ends with shipping. Some businesses also consider inventory management, supply chain management, order processing, quality control and customer support as a part of order fulfillment (Schwarz, 2020).

- Reverse Logistics: It often happens that the material you have received has some defects or problems. Such materials can be treated at the manufacturing unit, but sometimes it becomes essential to send them back to the suppliers. The process employed to deliver goods back to the upstream point is known as ‘Reverse Logistics’. Many companies specifically operate in the area of Reverse Logistics. For instance, GLS Logistics and International Shipping is a courier company that directly picks up the products from consumers and returns them to the seller of any other location (Tirelli, 2021).

Check Your Understanding

Answer the question(s) below to see how well you understand the topics covered above. You can retake it an unlimited number of times.

Use this quiz to check your understanding and decide whether to (1) study the previous section further or (2) move on to the next section.

Check Your Understanding: Components of Inbound and Outbound Logistics

Interactive activity unavailable in this format

Text-based alternative to interactive activity available in Chapter 2.6.

Overall Activity Feedback

It is important to understand the activities in Inbound and Outbound Logistics. Procurement or sourcing is also known as purchasing of goods or services from international suppliers. Material Handling is the function of moving the right material to the right place, at the right time, in the right amount, in sequence, and in the right position or condition to minimize production cost. In Warehousing and Transportation activities, Inbound and Outbound Logistics overlap. Reverse Logistics moves the goods or problem inventories from downstream to upstream.

Media Attributions and References

CognexTV. (2021, November 8). Inbound logistics solutions – machine vision & barcode reading for distribution & fulfillment [Video]. YouTube. https://youtu.be/Maz17CvqJa4

Elevate. (2018). [Inbound logistics] [Photograph]. Unsplash. https://unsplash.com/photos/dI-aXC7DWpQ

Nebov, J. (2021). Forklift in warehouse [Photograph]. Unsplash. https://unsplash.com/photos/seTS7bvcr0A

PLS Logistics Services. (2019, April 18). Why is logistics management important? [Video]. YouTube. https://youtu.be/eF1aYwDmppM

Tata Steel Jobs. (2018, June 15). Discover the world of outbound logistics within Tata Steel [Video]. YouTube. https://youtu.be/5RH9xMAANf8

Planning, Implementing, and Controlling the efficient, effective forward and reverse flow and storage of goods, services and related information inside a company.

Planning, Implementing, and Controlling the efficient, effective forward and reverse flow and storage of goods, services and related information moving outside a company.

The act of storing something in a warehouse.

The act of moving goods from origin to destination using different modes such as air, land, sea and pipelines.

Storage area for goods.