2 Organizing for Project Management

2.1 What is Project Management?

The management of construction projects requires knowledge of modern management as well as an understanding of the design and construction process. Construction projects have a specific set of objectives and constraints such as a required time frame for completion. While the relevant technology, institutional arrangements or processes will differ, the management of such projects has much in common with the management of similar types of projects in other specialty or technology domains such as aerospace, pharmaceutical and energy developments.

Generally, project management is distinguished from the general management of corporations by the mission-oriented nature of a project. A project organization will generally be terminated when the mission is accomplished. Resources must be mobilized and then demobilized for a project; it has a beginning and an end. Decades ago, according to the Project Management Institute (PMI), the discipline of project management could be defined as follows: [re. R. M. Wideman, “The PMBOK Report — PMI Body of Knowledge Standard,” Project Management Journal, Vol. 17, No. 3, August l986, pp. l5-24.]

Project management is the art of directing and coordinating human and material resources throughout the life of a project by using modern management techniques to achieve predetermined objectives of scope, cost, time, quality and participation satisfaction.

Today, we might add objectives such as health and safety or sustainability. Today, the PMI defines project management more broadly as [accessed 2023-08-31 https://www.pmi.org/about/learn-about-pmi/what-is-project-management ]:

Project management is the use of specific knowledge, skills, tools and techniques to deliver something of value to people.

Since this definition would be just as apt for services and other products, it is not precise enough to be of use, so we will use the old definition in this book.

In contrast to a project-centric perspective, the general management of corporations and government agencies assumes a broader outlook with greater continuity of operations. Nevertheless, there are sufficient similarities as well as differences between the two so that many modern management techniques developed for general management, such as continuous improvement and supply chain management, may be adapted for project management.

The basic ingredients for a project management framework [Halpin, Daniel W. and Ronald W. Woodhead, Construction Management, John Wiley and Sons, 1980., and accessed 2023-08-31 https://www.pmi.org/about/learn-about-pmi/what-is-project-management ] may be represented schematically in Figure 2-1. A working knowledge of general management and familiarity with the special knowledge domain (such as housing) related to the project are indispensable. Supporting disciplines such as computer science and decision science may also play an important role. In fact, modern management practices and various special knowledge domains have absorbed various techniques or tools which were once identified only with the supporting disciplines. For example, computer-based information systems, decision support systems, and AI applications are now common-place tools for general management. Similarly, many operations research techniques such as optimization and network analysis are now widely used in many knowledge or application domains. Leadership training and skills are also central to management of projects. Hence, the representation in Figure 2-1 reflects only the sources from which the project management framework evolves.

Figure 2-1: Basic Ingredients in Project Management

Specifically, project management in construction encompasses a set of objectives which may be accomplished by implementing a series of operations subject to resource constraints. There are potential conflicts between the stated objectives with regard to scope, cost, time and quality, and the constraints imposed on human material and financial resources. These conflicts should be resolved at the onset of a project by making the necessary trade-offs or creating new alternatives. Subsequently, the functions of project management for construction generally include the following:

- Specification of project objectives and plans including delineation of scope, budgeting, scheduling, setting performance requirements, and selecting project participants.

- Maximization of efficient resource utilization through procurement of labor, materials and equipment according to the prescribed schedule and plan.

- Implementation of various operations through proper coordination and control of planning, design, estimating, contracting and construction in the entire process.

- Development of effective communications and mechanisms for resolving conflicts among the various participants.

Good project management requires effective project managers. The Project Management Institute identifies the core roles and responsibilities of a project manager as [ https://www.pmi.org/about/learn-about-pmi/who-are-project-managers accessed 2023-08-31]:

- Identify project goals, needs, and scope

- Plan, monitor, and document tasks throughout a project

- Ensure all tasks, deliverables, and project materials are delivered promptly

- Manage all resources necessary for project execution

- Foster effective communication with stakeholders concerning project status

- Foresee and strategically eliminate blockers and potential risks

- Document each step of the process using various project management tools

- Ensure top-quality results and success for a project

PMI offers and supports certifications like the Project Management Professional Certification (PMP) as a way to help learn the skills required to effectively take on these core roles and responsibilities. In the US and Canada, there are many construction management programs offering bachelors degrees that focus on similar sets of skills. On-the-job training and experience are also necessary to master these skills.

2.2 Modern and Traditional Management Theories

Management theory advances with new scientific knowledge, and it can be influenced by social and political trends. For example, in a discussion of traditional and modern organizational management at [ https://www.mbaknol.com/management-concepts/traditional-management-model-vs-modern-management-model/ accessed 2023-08-31], modern organizational management is described as having a:

“ . . . focus on networking and collaborating, emphasized on dynamic nature of communication and importance of integration of individual and organizational interests, which largely depends on soft skill development such as consensus building, tacit knowledge, experience, learning, intuition, self-confidence, flexibility, prioritization of problems, working under pressure and ambiguity tolerance.”

, whereas traditional organizational management may be described as being hierarchical, statically organized, and disciplined. Effective organizations often combine elements of traditional and modern approaches.

Rather than our simple modern versus traditional perspective, Villanova University argues that there are three classes of management theories (not mutually exclusive, so they can be combined) on its web site [ https://www.villanovau.com/articles/leadership/an-overview-of-management-theories/ accessed 2023-08-31] :

- Classical management theory: which emerged from the Industrial Revolution and revolves around maximizing efficiency and production using methods including approaches such as Taylorism.

- Behavioral management theory: which considers human (emotional and psychological) and social elements as critical for successful management.

- Modern management theory: emerged from World War II focusing on mathematical and systems models and methods, including optimization techniques.

Types of modern management theories typically include:

- Quantitative or scientific theories: use of quantitative and analytical tools to optimize resource allocation and processes.

- Systems theories: use of models of organizations (such as a projects) as systems of systems, composed of interrelated parts and systems that are managed to achieve a goal.

- Contingency theories: pragmatic, conditional and opportunistic theory that optimal management depends on situation, context and environment.

Understanding these competing theories and strategies, or at least being aware of their existence helps to make wise decisions about one’s own approach to project management and leadership. Sustainable competitive advantage stems primarily from good management strategy. As Michael Porter of the Harvard Business School argues:

“Strategy is creating fit among a company’s activities. The success of a strategy depends on doing many things well – not just a few – and integrating among them. If there is no fit among activities, there is no distinctive strategy and little sustainability.”

In this view, successful firms must improve and align the many processes underway to their strategic vision. Strategic positioning in this fashion requires:

- Creating a unique and valuable position.

- Making trade-offs compared to competitors

- Creating a “fit” among a company’s activities.

Project managers should be aware of the strategic position and management philosophy of their own organization and the other organizations involved in the project. The project manager faces the difficult task of trying to align the goals and strategies of these various organizations to accomplish the project goals. For example, the owner of an industrial project may define a strategic goal as being first to market with new products. In this case, facilities development must be oriented to fast-track, rapid construction. As another example, a contracting firm may see their strategic advantage in new technologies and emphasize profit opportunities from value engineering (as described in Chapter 3).

2.3 Strategic Planning and Project Programming

The programming of capital projects is shaped by the strategic plan of an organization, which is influenced by market demands and resources constraints. The programming process associated with planning and feasibility studies sets the priorities and timing for initiating various projects to meet the overall objectives of the organizations. However, once this decision is made to initiate a project, market pressure may dictate early and timely completion of the facility.

Among various types of construction, the influence of market pressure on the timing of initiating a facility is most obvious in industrial construction. Demand for an industrial product (such as a new AI computer chip) may be short-lived, and if a company does not hit the market first, there may not be demand for its product later. With intensive competition for national and international markets, the trend of industrial construction moves toward shorter project life cycles, particularly in technology intensive industries.

In order to gain time, some owners are willing to forego a thorough planning and feasibility study so as to proceed on a project with inadequate definition of the project scope. Invariably, subsequent changes in project scope will increase construction costs; however, profits derived from earlier facility operation often justify the increase in construction costs. Generally, if the owner can derive reasonable profits from the operation of a completed facility, the project is considered a success even if construction costs far exceed the estimate based on an inadequate scope definition. This attitude may be attributed in large part to the uncertainties inherent in construction projects. It is difficult to argue that profits might be even higher if construction costs could be reduced without increasing the project duration. However, some projects, notably some nuclear power plants, are clearly unsuccessful and abandoned before completion, and their demise must be attributed at least in part to inadequate planning and poor feasibility studies.

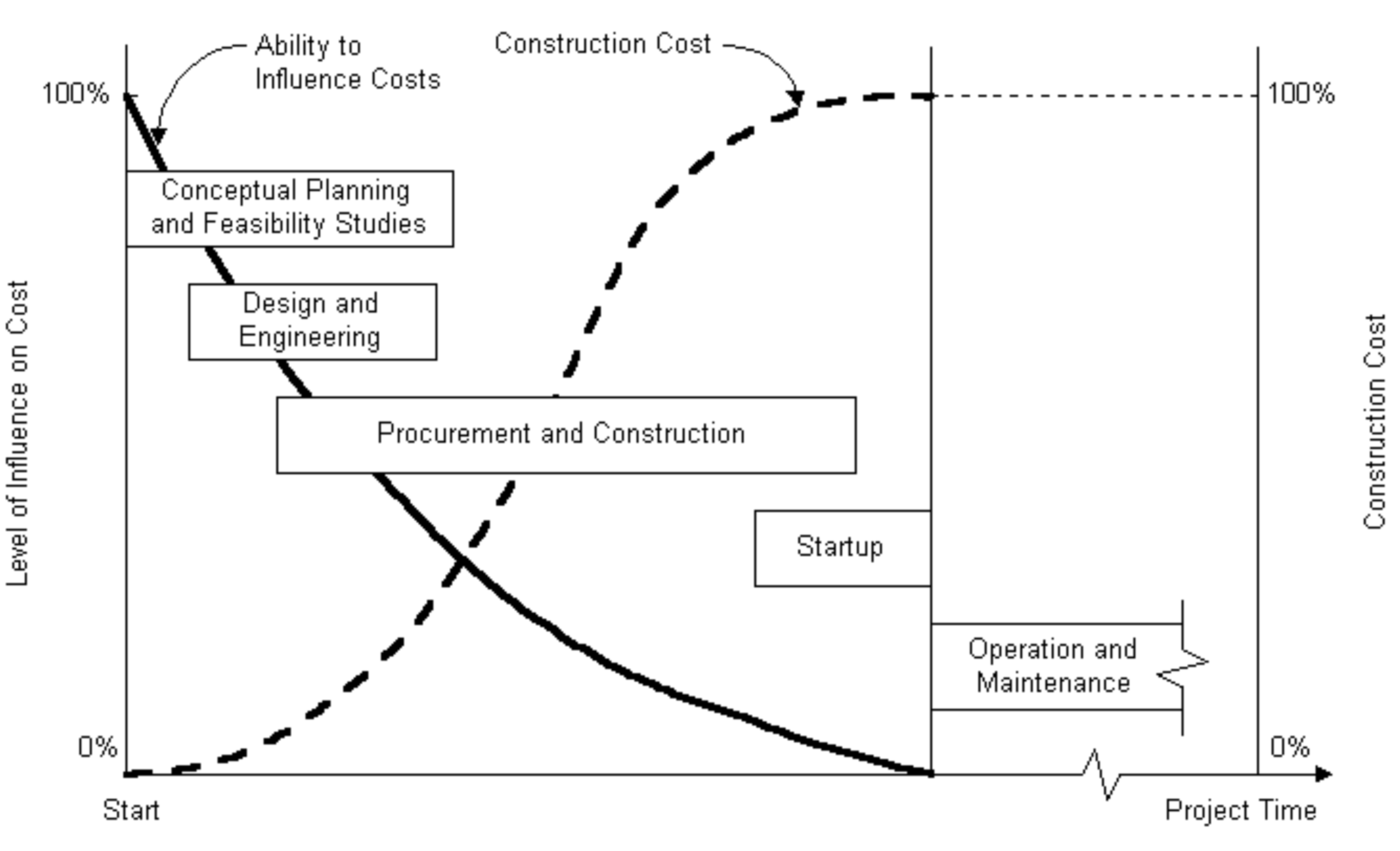

The owner or facility sponsor holds the key to influence the construction costs of a project, because any decision made at the beginning stage of a project life cycle has far greater influence than those made at later stages, as shown schematically in Figure 2-2. Moreover, the design and construction decisions will influence the continuing operating costs and, in many cases, the revenues over the facility lifetime. Therefore, an owner should obtain the expertise of professionals to provide adequate planning and feasibility studies. Many owners do not maintain an in-house engineering and construction management capability, and they should consider the establishment of an ongoing relationship with outside consultants in order to respond quickly to requests. Even among those owners who maintain engineering and construction divisions, many treat these divisions as reimbursable, independent organizations. Such an arrangement should not discourage their legitimate use as false economies in reimbursable costs from such divisions can indeed be very costly to the overall organization.

Figure 2-2: Ability to Influence Construction Cost Over Time

Finally, the initiation and execution of capital projects places demands on the resources of the owner and the professionals and contractors to be engaged by the owner. For very large projects, it may bid up the price of engineering services as well as the costs of materials and equipment and the contract prices of all types. Consequently, such factors should be taken into consideration in determining the timing of a project.

Example 2-1: Setting priorities for projects

A developer planned to acquire an empty former mall on 20 acres of land in the southeast of a metropolitan area which consists of well-established, densifying suburbs for middle income families. An architectural/engineering (A/E) firm was engaged to design a mixed-use, indoor-outdoor shopping center on the 20-acre plot. One year later, the developer purchased a 30 acre former factory site in the northwest of the same metropolitan area and designated this site also for a shopping center. The A/E firm was again engaged to design a shopping center at this new location.

The A/E firm was kept completely in the dark while the acquisition of the land in the northwest quietly took place. When the plans and specifications for the southeast shopping center were completed, the owner informed the A/E firm that it would not proceed with the construction of the southeast shopping center for the time being. Instead, the owner urged the A/E firm to produce a new set of similar plans and specifications for the northwest shopping center as soon as possible, even at the sacrifice of cost saving measures, such as potential adaptive reuse of the factory. When the plans and specifications for the northwest shopping center were ready, the owner immediately authorized its construction. However, it took another three years before the southeast shopping center was finally built.

The reason behind the change of plans was that the owner discovered the availability of the factory land in the northwest which was rezoned and could be re-developed into mixed-use. The immediate construction of the northwest shopping center was incentivized by the city with subsidies. Thus, the owner was able to recoup enough cash flow in three years to construct the southeast shopping center in addition to financing the construction of the northwest shopping center and the environmental remediation required on part of its site.

While the owner did not want the construction cost of the northwest shopping center to run wild, it apparently was satisfied with the cost estimate based on the detailed plans of the southeast shopping center. Thus, the owner had a general idea of what the construction cost of the northwest shopping center would be, and it did not wish to wait for a more refined cost estimate until the detailed plans for that center were ready. To the owner, the timeliness of completing the construction of the northwest shopping center was far more important than reducing the construction cost in fulfilling its investment objectives.

Example 2-2: Resource Constraints for Mega Projects

A major problem with mega projects is the severe strain placed on the environment, particularly on the resources in the immediate area of a construction project. “Mega” or “macro” projects involve construction of very large facilities such as the the Panama Canal constructed in the 1900’s, the Alaska pipeline constructed in the 1970’s, or The Hudson River Rail Tunnel (or Gateway Project) [The New York Times] currently under construction. According to [Bloomberg], “The cost of the project has climbed to $16.1 billion, the Gateway Development Commission said in August — an estimate that is 14% higher than the 2021 projection. The start of major construction, once proposed for mid-2023, is now expected in mid-2024.” The limitations in some or all of the basic elements required for the successful completion of a mega project include:

-

- engineering design professionals to provide sufficient manpower to complete the design within a reasonable time limit.

- construction supervisors with capacity and experience to direct large projects.

- the number of construction workers with proper skills to do the work.

- the market to supply materials in sufficient quantities and of required quality on time.

- the ability of the local infrastructure to support the large number of workers over an extended period of time, including housing, transportation and other services.

To compound the problem, mega projects are often constructed in remote environments away from major population centers and subject to severe climate conditions. Consequently, special features of each mega project must be evaluated carefully.

Many people are aware that mega-projects typically go off the rails in terms of cost and schedule, sometimes by several hundred precent. The causes for this are widely speculated and studied. Bent Flyvbjerg in the Said Business School at the University of Oxford has observed that the costs such projects are often underestimated intentionally and inspiring stories created in order to achieve commitment from owners such as cities and national governments. Others argue that these projects fail because of their overwhelming complexity. The National Academy of Construction has published at least 17 Executive Insights into Large Complex Projects, including why they most often fail and what can be done about it.

2.4 Effects of Project Risks on Organization

The uncertainty in undertaking a construction project comes from many sources and involves most participants in the project. Uncertainty leads to risks, which we define in this text as the product of the probability and impact of an event (e.g. an unexpected rapid rise in the cost of lumber). As each participant tries to minimize its own risk, conflicts arise, and those conflicts among various participants can be detrimental to the project. Owners can moderate such conflicts as they hold the key to risk assignment through proper contractual relations with other participants. Failure to recognize this responsibility by the owner often leads to undesirable results. Fortunately, over the last few decades risk-sharing contracts have gained acceptance by many state and federal governments. Since this type of contract acknowledges the responsibilities of the owners, so that risks are allocated where they are best managed, the contract price and final project cost are expected to be lower than those in which all risks are assigned to contractors.

In approaching the problem of uncertainty, it is important to recognize that incentives must be provided if any of the participants is expected to take a greater risk. The willingness of a participant to accept risks often reflects the professional competence of that participant as well as its propensity to risk. However, society’s perception of the potential liabilities of the participant can affect the attitude of risk-taking for all participants. When a claim is made against one of the participants, it is difficult for the public to know whether a fraud has been committed, or simply that an accident has occurred.

Risks in construction projects may be classified in a number of ways. One form of classification is as follows:

- Socioeconomic factors

- Environmental protection

- Public safety regulation

- Economic instability

- Exchange rate fluctuation

- Organizational relationships

- Contractual relations

- Attitudes of participants

- Communication

- Technological problems

- Design assumptions

- Site conditions

- Construction procedures

- Construction occupational safety

The environmental protection movement has contributed to the uncertainty for construction because of the inability to know what will be required and how long it will take to obtain approval from the regulatory agencies. The requirements of continued re-evaluation of problems and the lack of definitive criteria which are practical have also resulted in added costs. Public safety regulations have similar effects, which have been most noticeable in the energy field involving nuclear power plants (even for SMRs – small modular reactors) and pipelines. The situation has created constantly shifting guidelines for engineers, constructors and owners as projects move through the stages of planning to construction. These moving targets add a significant new dimension of uncertainty which can make it virtually impossible to schedule and complete work at budgeted cost. Economic conditions reinforce the climate of uncertainty with fluctuating inflation and interest rates.

During periods of economic expansion, major capital expenditures are made by industries and bid up the cost of construction. In order to control costs, some owners attempt to use fixed price contracts so that the risks of unforeseen contingencies related to an overheated economy are passed on to contractors. However, contractors will raise their prices to compensate for the additional risks.

The risks related to organizational relationships may appear to be unnecessary but are quite real. Strained relationships may develop between various organizations involved in the design/construct process. When problems occur, discussions often center on responsibilities rather than project needs at a time when the focus should be on solving the problems. Cooperation, communication and building trust between the parties are discouraged for fear of the effects of impending litigation. This barrier to communication results from the ill-conceived notion that uncertainties resulting from technological problems can be eliminated by appropriate contract terms. Consequently, the costs of constructed facilities continue to increase.

The risks related to technological problems are familiar to the design/construct professions which have some degree of control over this category. However, because of rapid advances in new technologies which present new problems to designers and constructors, technological risk has become greater in many instances. Certain design assumptions which have served the professions well in the past may become obsolete in dealing with new types of facilities which may have greater complexity or scale or both. Site conditions, particularly subsurface conditions which always present some degree of uncertainty, can create an even greater degree of uncertainty for facilities with heretofore unknown characteristics during operation (such as “Brownfield” sites, former industrial sites on which multi-residential units are often developed). Because construction procedures may not have been fully anticipated, the design may have to be modified after construction has begun.

If each of the problems cited above can cause uncertainty, the combination of such problems is often regarded by all parties as being out of control and inherently risky. Thus, the issue of liability has taken on major proportions and has influenced the practices of engineers and constructors, who in turn have influenced the actions of the owners.

Many owners understand the problems of risks and seek to address some of these problems. For example, some owners turn to those organizations that offer complete capabilities in planning, design, and construction, and tend to avoid breaking the project into major components to be undertaken individually by specialty participants. Proper coordination throughout the project duration and good organizational communication can avoid delays and costs resulting from fragmentation of services, even though the components from various services are eventually integrated.

Attitudes of cooperation can be readily applied to the private sector, but only in special circumstances can they be applied to the public sector. The ability to deal with complex issues is often precluded in the competitive bidding which is usually required in the public sector. The situation becomes more difficult with the proliferation of regulatory requirements and resulting delays in design and construction while awaiting permits and approvals from government officials who do not participate in the risks of the project.

2.5 Organization of Project Participants

The top management of the owner sets the overall policy and selects the appropriate organization to take charge of a proposed project. Its policy will dictate how the project life cycle is divided among organizations and which professionals should be engaged. Decisions by the top management of the owner will also influence the organization to be adopted for project management. In general, there are many ways to decompose a project into stages. The most typical ways are:

- Sequential processing whereby the project is divided into separate stages and each stage is carried out successively in sequence.

- Parallel processing whereby the project is divided into independent parts such that all stages for those parts are carried out simultaneously.

- Staggered processing whereby the stages may be overlapping, such as the use of phased design-construct procedures for fast-track operation.

It should be pointed out that some decompositions may work out better than others, depending on the circumstances. In any case, the prevalence of decomposition makes the subsequent integration particularly important. The critical issues involved in organization for project management are:

- How many organizations are involved?

- What are the relationships among the organizations?

- When are the various organizations brought into the project?

There are two basic approaches to organize for project implementation, even though many variations may exist as a result of different contractual relationships adopted by the owner and builder. These basic approaches are divided along the following lines:

- Separation of organizations. Numerous organizations serve as consultants or contractors to the owner, with different organizations handling design and construction functions. Typical examples which involve different degrees of separation are:

- Traditional sequence of design and construction

- Professional construction management

- Integration of organizations. A single or joint venture consisting of a number of organizations with a single command undertakes both design and construction functions. Two extremes may be cited as examples:

- Owner-builder operation in which all work will be handled in house by force account.

- Turnkey operation in which all work is contracted to a vendor which is responsible for delivering the completed project

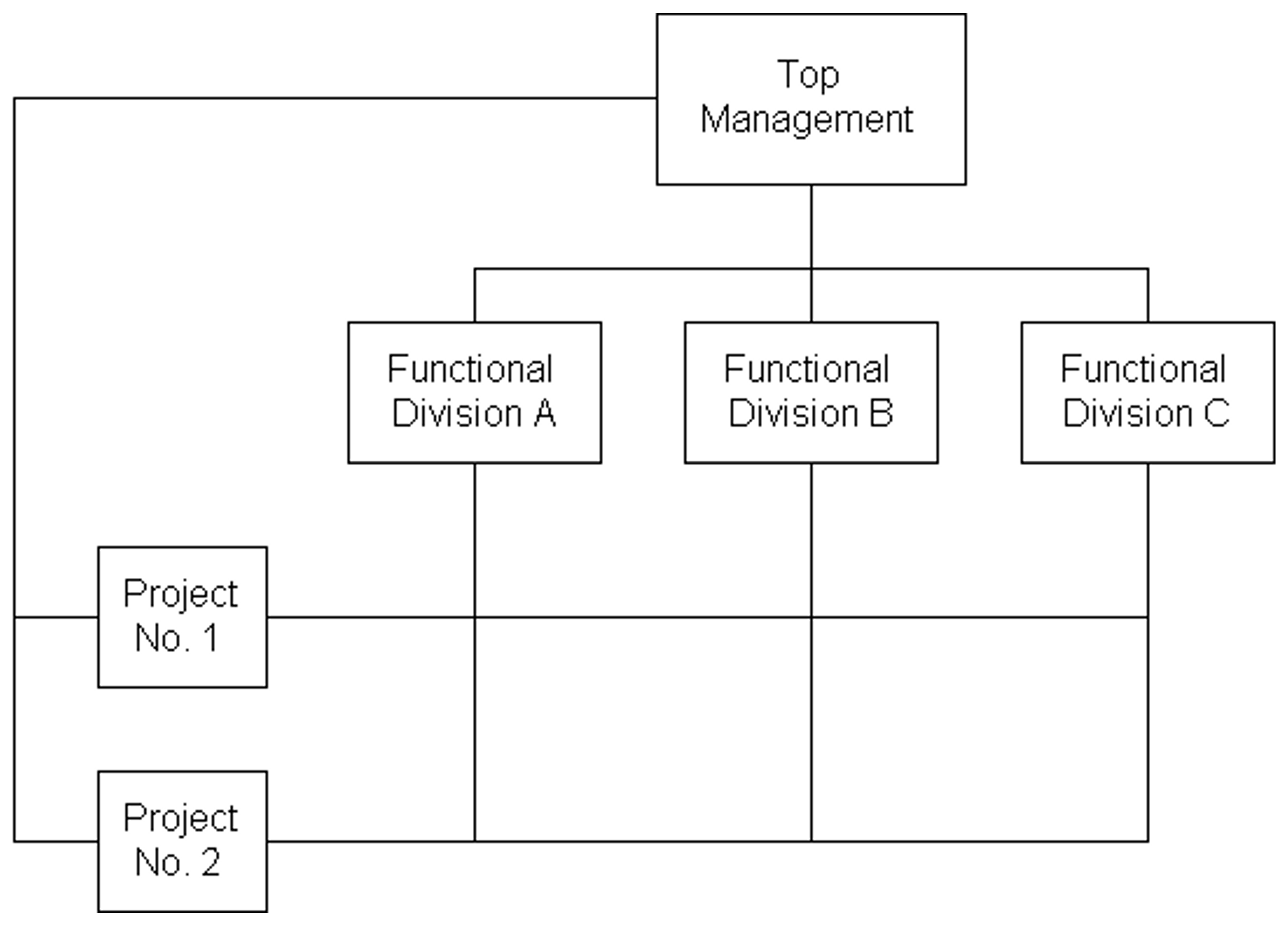

Since construction projects may be managed by a spectrum of participants in a variety of combinations, the organization for the management of such projects may vary from case to case. On one extreme, each project may be staffed by existing personnel in the functional divisions of the organization on an ad-hoc basis as shown in Figure 2-3 until the project is completed. This arrangement is referred to as the matrix organization as each project manager must negotiate all resources for the project from the existing organizational framework. This is typical for the way projects are managed within a large AE (architectural/engineering) firm for example, such as WSJ.

Figure 2-3: A Matrix Organization

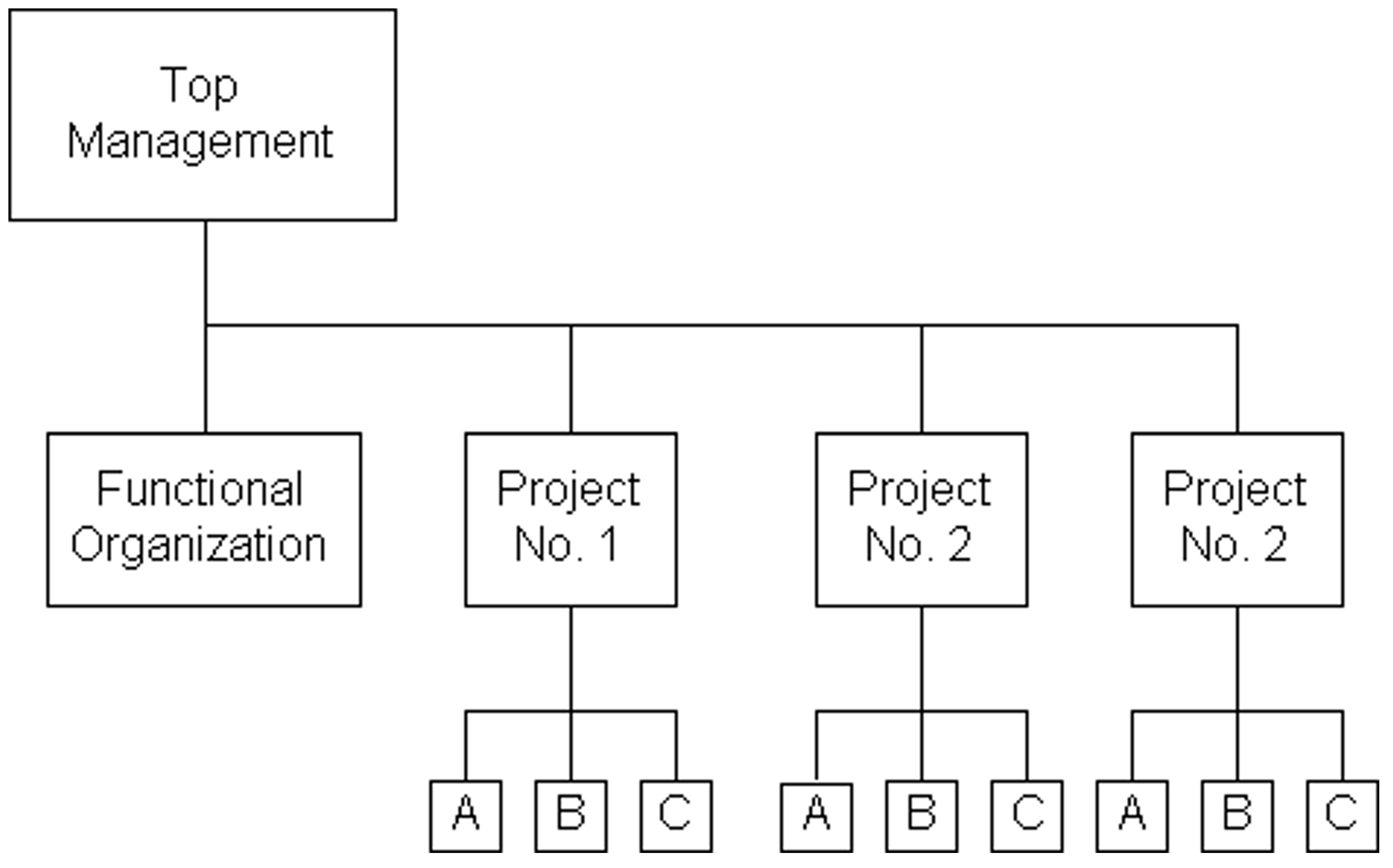

On the other hand, the organization may consist of a relatively small central functional staff for the exclusive purpose of supporting various projects, each of which has its functional divisions as shown in Figure 2-4. This decentralized set-up is referred to as the project-oriented organization as each project manager has autonomy in managing the project. A large construction management firm such as Bechtel would reflect this approach. There are many variations of management style between these two extremes, depending on the objectives of the organization and the nature of the construction project. For example, a large chemical company with in-house staff for planning, design and construction of facilities for new product lines will naturally adopt the matrix organization. On the other hand, a construction company whose existence depends entirely on the management of certain types of construction projects may find the project-oriented organization particularly attractive. While organizations may differ, the same basic principles of management structure are applicable to most situations.

Figure 2-4: A Project-Oriented Organization

To illustrate various types of organizations for project management, we shall consider two examples, the first one representing an owner organization while the second one representing the organization of a construction management consultant under the direct supervision of the owner.

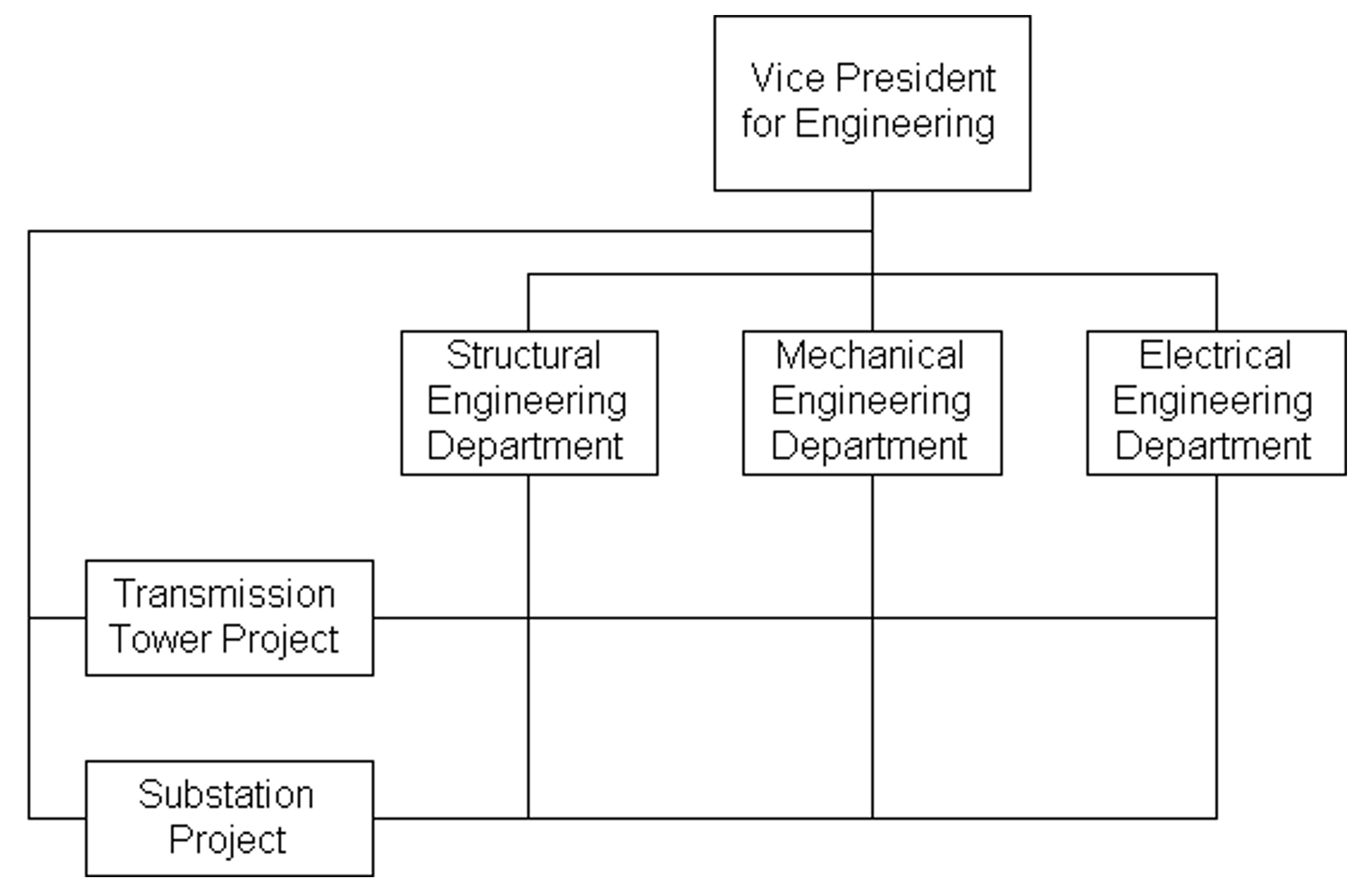

Example 2-3: Matrix Organization of an Engineering Division

The Engineering Division of an Electric Power and Light Company has functional departments as shown in Figure 2-5. When small scale projects such as the addition of a transmission tower or a sub-station are authorized, a matrix organization is used to carry out such projects. For example, in the design of a transmission tower, the professional skill of a structural engineer is most important. Consequently, the leader of the project team will be selected from the Structural Engineering Department while the remaining team members are selected from all departments as dictated by the manpower requirements. On the other hand, in the design of a new sub-station, the professional skill of an electrical engineer is most important. Hence, the leader of the project team will be selected from the Electrical Engineering Department.

Figure 2-5: The Matrix Organization in an Engineering Division

Example 2-4: Example of Construction Management Consultant Organization

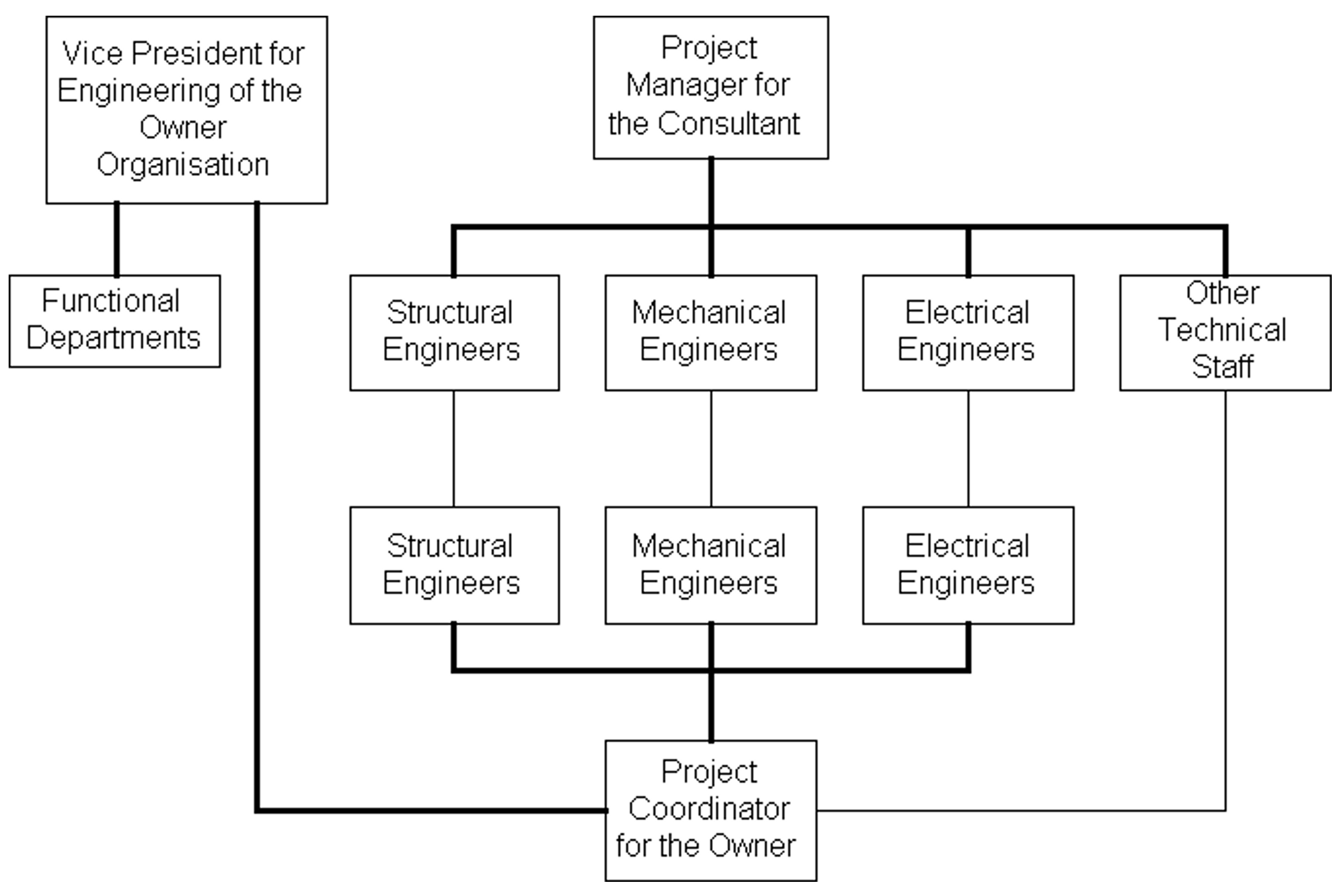

When the same Electric Power and Light Company in the previous example decided to build a new power plant, it engaged a construction management consultant to take charge of the design and construction completely. However, the company also assigned a project team to coordinate with the construction management consultant as shown in Figure 2-6.

Figure 2-6: Coordination between Owner and Consultant

Since the company eventually will operate the power plant upon its completion, it is highly important for its staff to monitor the design and construction of the plant. Such coordination allows the owner not only to assure the quality of construction but also to be familiar with the design to facilitate future operation and maintenance. Note the close direct relationships of various departments of the owner and the consultant. Since the project will last for many years before its completion, the staff members assigned to the project team are not expected to rejoin the Engineering Department but will probably be involved in the future operation of the new plant. Thus, the project team can act independently toward its designated mission.

2.6 Traditional Designer-Constructor Sequence

For ordinary projects of moderate size and complexity, the owner often employs a designer (an architectural/engineering firm) which prepares the detailed plans and specifications for the constructor (a general contractor). The designer also acts on behalf of the owner to oversee the project implementation during construction. The general contractor is responsible for the construction itself even though the work may actually be undertaken by a number of specialty subcontractors.

The owner usually negotiates the fee for service with the architectural/engineering (A/E) firm. In addition to the responsibilities of designing the facility, the A/E firm also exercises to some degree supervision of the construction as stipulated by the owner. Traditionally, the A/E firm regards itself as design professionals representing the owner who should not communicate with potential contractors to avoid collusion or conflict of interest. Field inspectors working for an A/E firm usually follow through the implementation of a project after the design is completed and seldom have extensive input in the design itself. Most A/E firms only provide observers rather than inspectors in the field. Even the shop drawings of fabrication or construction schemes submitted by the contractors for approval are reviewed with a disclaimer of responsibility by the A/E firms.

The owner may select a general constructor either through competitive bidding or through negotiation. Public agencies are required to use the competitive bidding mode, while private organizations may choose either approach. In using competitive bidding, the owner is forced to use the designer-constructor sequence since detailed plans and specifications must be ready before inviting bidders to submit their bids. If the owner chooses to use a negotiated contract, it is free to use phased construction if it so desires.

The general contractor may choose to perform all or part of the construction work, or it may act only as a manager by subcontracting all the construction to subcontractors. The general contractor may also select the subcontractors through competitive bidding or negotiated contracts. The general contractor may ask a number of subcontractors to quote prices for the subcontracts before submitting its bid to the owner. However, the subcontractors often cannot force the winning general contractor to use them on the project. This situation may lead to practices known as bid shopping and bid peddling. Bid shopping refers to the situation when the general contractor approaches subcontractors other than those whose quoted prices were used in the winning contract in order to seek lower priced subcontracts. Bid peddling refers to the actions of subcontractors who offer lower priced subcontracts to the winning general subcontractors in order to dislodge the subcontractors who originally quoted prices to the general contractor prior to its bid submittal. In both cases, the quality of construction may be sacrificed, and some state statutes forbid these practices for public projects.

Although the designer-constructor sequence is still widely used because of the public perception of fairness in competitive bidding, many private owners recognize the disadvantages of using this approach when the project is large and complex and when market pressures require a shorter project duration than that which can be accomplished by using this traditional method.

2.7 Professional Construction Management

Professional construction management refers to a project management team consisting of a professional construction manager and other participants who will carry out the tasks of project planning, design and construction in an integrated manner. Contractual relationships among members of the team are intended to minimize adversarial relationships and contribute to greater response within the management group. A professional construction manager is a firm specialized in the practice of professional construction management which includes:

- Work with owner and the A/E firms from the beginning and make recommendations on design improvements, construction technology, schedules and construction economy.

- Propose design and construction alternatives if appropriate, and analyze the effects of the alternatives on the project cost and schedule.

- Monitor subsequent development of the project in order that these targets are not exceeded without the knowledge of the owner.

- Coordinate procurement of material and equipment and the work of all construction contractors, and monthly payments to contractors, changes, claims and inspection for conforming design requirements.

- Perform other project related services as required by owners.

Professional construction management is usually used when a project is very large or complex. The organizational features that are characteristics of mega-projects can be summarized as follows:[6]

- The overall organizational approach for the project will change as the project advances. The “functional” organization may change to a “matrix” which may change to a “project” organization (not necessarily in this order).

- Within the overall organization, there will probably be functional, project, and matrix suborganizations all at the same time. This feature greatly complicates the theory and the practice of management, yet is essential for overall cost effectiveness.

- Successful giant, complex organizations usually have a strong matrix-type suborganization at the level where basic cost and schedule control responsibility is assigned. This suborganization is referred to as a “cost center” or as a “project” and is headed by a project manager. The cost center matrix may have participants assigned from many different functional groups. In turn, these functional groups may have technical reporting responsibilities to several different and higher tiers in the organization. The key to a cost-effective effort is the development of this project suborganization into a single team under the leadership of a strong project manager.

- The extent to which decision-making will be centralized or decentralized is crucial to the organization of the mega-project.

Consequently, it is important to recognize the changing nature of the organizational structure as a project is carried out in various stages.

Example 2-5: Managing of the Alaska Pipeline Project

The Alaska Pipeline Project was the largest, most expensive private construction project in the 1970’s, which encompassed 800 miles, thousands of employees, and 10 billion (1980) dollars.

At the planning stage, the owner (a consortium) employed a Construction Management Contractor (CMC) to direct the pipeline portion, but it retained centralized decision making to assure alignment and to integrate the effort of the CMC with the pump stations and the terminals performed by another contractor. The CMC also centralized its decision making in directing over 400 subcontractors and thousands of vendors. Because there were 19 different construction camps and hundreds of different construction sites, this centralization caused delays in decision making.

At about the 15% point of physical completion, the owner decided to reorganize the decision-making process and change the role of the CMC. The new organization was a combination of owner and CMC personnel assigned within an integrated organization. (In Ontario, this is similar to how the Darlington NPP RFR project was restructured in the early 2020s). The objective was to develop a single project team responsible for controlling all subcontractors. Instead of having nine tiers of organization from the General Manager of the CMC to the subcontractors, the new organization had only four tiers from the Senior Project Manager of the owner to subcontractors. Besides unified direction and coordination, this reduction in tiers of organization greatly improved communications and the ability to make and implement decisions. The new organization also allowed decentralization of decision making by treating five sections of the pipeline at different geographic locations as separate projects, with a section manager responsible for all functions of the section as a profit center.

At about 98% point of physical completion, all remaining activities were to be consolidated to identify single bottom-line responsibility, to reduce duplication in management staff, and to unify coordination of remaining work. Thus, the project was first handled by separate organizations but later was run by an integrated organization with decentralized profit centers. Finally, the organization in effect became small and was ready to be phased out of operation.

Example 2-6: Managing the Channel Tunnel Construction from Britain to France

The underground railroad tunnel from Britain to France is commonly called the Channel Tunnel or Chunnel. It was built by tunneling from each side. Starting in 1987, the tunnels had a breakthrough (they met underground, which was a good thing) in 1990.

Management turmoil dogged the project from the start. In 1989, seven of the eight top people in the construction organization left. There was a built-in conflict between the contractors and government overseers: “The fundamental thing wrong is that the contractors own less than 6% of Eurotunnel. Their interest is to build and sell the project at a profit. (Eurotunnel’s) interest is for it to operate economically, safely and reliably for the next 50 years.” (Alastair Morton, Eurotunnel CEO, quoted in ENR, 12/10/90, p. 56).

It will be intriguing to watch the NYC Gateway project over the next decade to see how it evolves its organizational structure in light of these preceding historical examples. Then, perhaps the reader can consider the eternal urgent question, “Does history repeat itself?”.

2.8 Owner-Builder Operation

In this approach an owner must have a steady flow of on-going projects in order to maintain a large work force for in-house operation. However, the owner may choose to subcontract a substantial portion of the project to outside consultants and contractors for both design and construction, even though it retains centralized decision making to integrate all efforts in project implementation.

Example 2-7: U.S. Army Corps of Engineers Organization

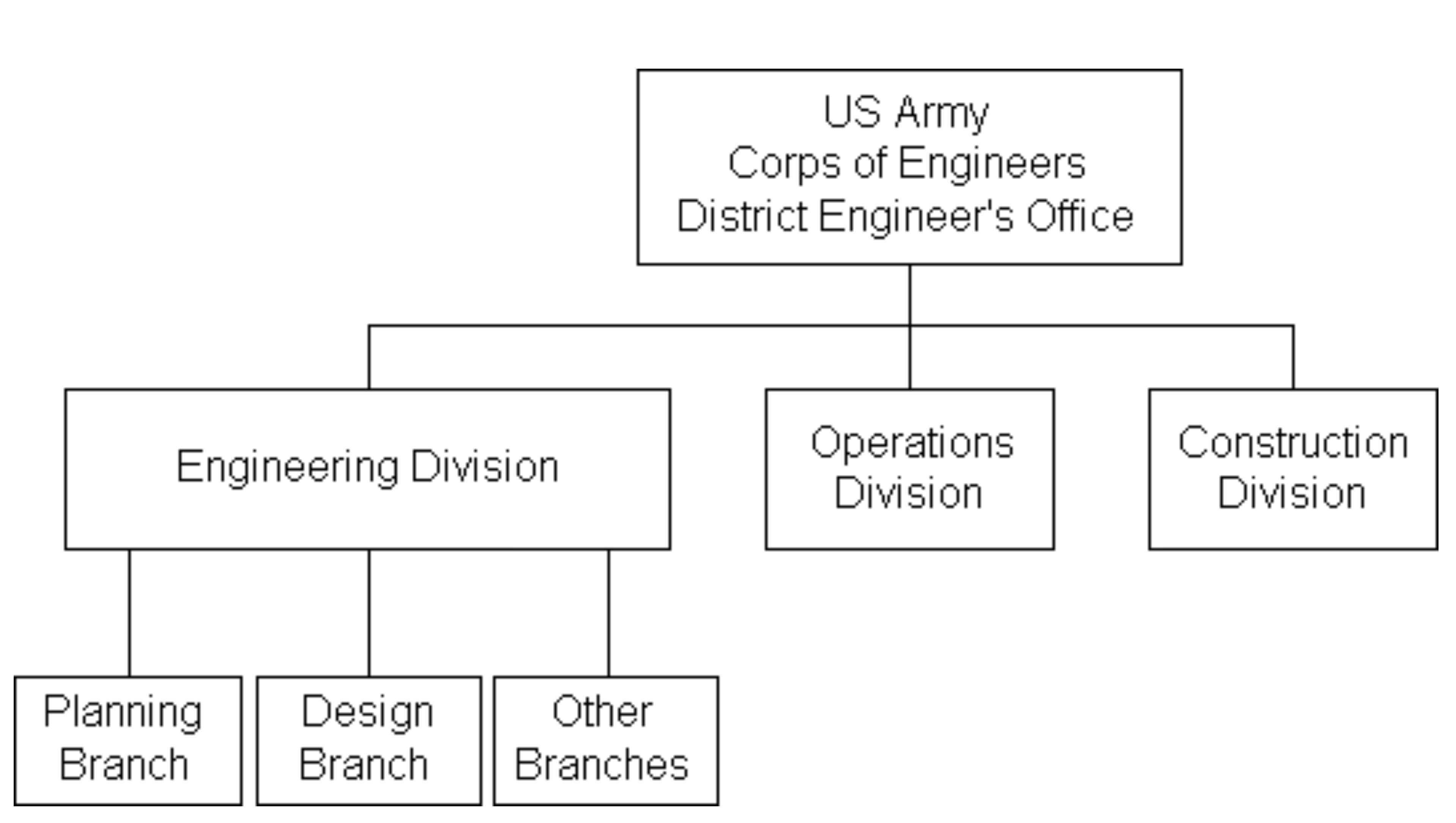

The District Engineer’s Office of the U.S. Army Corps of Engineers may be viewed as a typical example of an owner-builder approach as shown in Figure 2-7. In the District Engineer’s Office of the U.S. Corps of Engineers, there usually exist an Engineering Division and an Operations Division, and, in a large district, a Construction Division. Under each division, there are several branches. Since the authorization of a project is usually initiated by the U.S. Congress, the planning and design functions are separated in order to facilitate operations. Since the authorization of the feasibility study of a project may precede the authorization of the design by many years, each stage can best be handled by a different branch in the Engineering Division. If construction is ultimately authorized, the work may be handled by the Construction Division or by outside contractors. The Operations Division handles the operation of locks and other facilities which require routine attention and maintenance.

When a project is authorized, a project manager is selected from the most appropriate branch to head the project, together with a group of staff drawn from various branches to form the project team. When the project is completed, all members of the team including the project manager will return to their regular posts in various branches and divisions until the next project assignment. Thus, a matrix organization is used in managing each project.

Figure 2-7: Organization of a District of Corps of Engineers

2.9 Turnkey Operation

Some owners wish to delegate all responsibilities of design and construction to outside consultants in a turnkey project arrangement. A contractor agrees to provide the completed facility on the basis of performance specifications set forth by the owner. The contractor may even assume the responsibility of operating the project if the owner so desires. In order for a turnkey operation to succeed, the owner must be able to provide a set of unambiguous performance specifications to the contractor and must have complete confidence in the capability of the contractor to carry out the mission.

This approach is the direct opposite of the owner-builder approach in which the owner wishes to retain the maximum amount of control for the design-construction process.

Example 2-8: Examples of a Turnkey Organization

A 150-MW power plant was proposed in 1985 by the Texas-New Mexico Power Company of Fort Worth, Texas, which would make use of the turnkey operation. [7] Upon approval by the Texas Utility Commission, a consortium consisting of H.B. Zachry Co., Westinghouse Electric Co., and Combustion Engineering, Inc. would design, build and finance the power plant for completion in 1990 for an estimated construction cost of $200 million in 1990 dollars. The consortium would assume total liability during construction, including debt service costs, and thereby eliminate the risks of cost escalation to rate payers, stockholders and the utility company management.

A more contemporary example is the 377-MW Great Plains Power Station project in which Canadian utility SaskPower selected Burns & McDonnell as its engineering, procurement and construction (EPC) contractor. Originally estimated at $780 million CDN, it is expected to be in service in 2024.

2.10 Leadership and Motivation for the Project Team

The project manager, in the broadest sense of the term, is the most important person for the success or failure of a project. The project manager is responsible for planning, organizing and controlling the project. In turn, the project manager receives authority from the management of the organization to mobilize the necessary resources to complete a project.

The project manager must be able to exert interpersonal influence in order to lead the project team. The project manager often gains the support of his/her team through a combination of the following:

- Formal authority resulting from an official capacity which is empowered to issue orders.

- Reward and/or penalty power resulting from their capacity to dispense directly or indirectly valued organization rewards or penalties.

- Expert power when the project manager is perceived as possessing special knowledge or expertise for the job.

- Attractive power because the project manager has a personality or other characteristics to convince others.

In a matrix organization, the members of the functional departments may be accustomed to a single reporting line in a hierarchical structure, but the project manager coordinates the activities of the team members drawn from functional departments. The functional structure within the matrix organization is responsible for priorities, coordination, administration and final decisions pertaining to project implementation. Thus, there are potential conflicts between functional divisions and project teams. The project manager must be given the responsibility and authority to resolve various conflicts such that the established project policy and quality standards will not be jeopardized. When contending issues of a more fundamental nature are developed, they must be brought to the attention of a high level in the management and be resolved expeditiously.

In general, the project manager’s authority must be clearly documented as well as defined, particularly in a matrix organization where the functional division managers often retain certain authority over the personnel temporarily assigned to a project. The following principles should be observed:

- The interface between the project manager and the functional division managers should be kept as simple as possible.

- The project manager must gain control over those elements of the project which may overlap with functional division managers.

- The project manager should encourage problem solving rather than role playing of team members drawn from various functional divisions.

2.11 Interpersonal Behavior in Project Organizations

While a successful project manager must be a good leader, other members of the project team must also learn to work together, whether they are assembled from different divisions of the same organization or even from different organizations. Some problems of interaction may arise initially when the team members are unfamiliar with their own roles in the project team, particularly for a large and complex project. These problems must be resolved quickly to develop an effective, functioning team.

Many of the major issues in construction projects require effective interventions by individuals, groups and organizations. The fundamental challenge is to enhance communication among individuals, groups and organizations so that obstacles in the way of improving interpersonal relations may be removed. Some behavior science concepts are helpful in overcoming communication difficulties that block cooperation and coordination. For example, team building exercises are common, effective, and easy to find on the internet. The power of the organization should be used judiciously in resolving conflicts.

The major symptoms of interpersonal behavior problems can be detected by experienced observers, and they are often the sources of serious communication difficulties among participants in a project. For example, members of a project team may avoid each other and withdraw from active interactions about differences that need to be dealt with. They may attempt to criticize and blame other individuals or groups when things go wrong. They may resent suggestions for improvement and become defensive to minimize culpability rather than take the initiative to maximize achievements. All these actions are detrimental to the project organization.

While these symptoms can occur to individuals at any organization, they are compounded if the project team consists of individuals who are put together from different organizations. Invariably, different organizations have different cultures or modes of operation. Individuals from different groups may not have a common loyalty and may prefer to expand their energy in the directions most advantageous to themselves instead of the project team. Therefore, no one should take it for granted that a project team will work together harmoniously just because its members are placed physically together in one location. On the contrary, it must be assumed that good communication can be achieved only through the deliberate effort of the top management of each organization contributing to the joint venture.

2.12 Owners and Contractors Perceptions on What Drives Project Success

Although owners and contractors may have different perceptions on project management for construction, they have a common interest in creating an environment leading to successful projects in which performance quality, completion time and final costs are within prescribed limits and tolerances. It is interesting therefore to note the opinions of some leading contractors and owners who were interviewed in 1984 (from J.E. Diekmann and K.B. Thrush, Project Control in Design Engineering, A Report to the Construction Industry Institute, The University of Texas at Austin, Texas, May 1986).

From the responses of six contractors, the key factors cited for successful projects are:

- well defined scope

- extensive early planning

- good leadership, management and first line supervision

- positive client relationship with client involvement

- proper project team chemistry

- quick response to changes

- engineering managers concerned with the total project, not just the engineering elements.

Conversely, the key factors cited for unsuccessful projects are:

- ill-defined scope

- poor management

- poor planning

- breakdown in communication between engineering and construction

- unrealistic scope, schedules, and budgets

- many changes at various stages of progress

- lack of good project control

Four decades and hundreds of research projects later, the Construction Industry Institute in Austin Texas lists a number of “best practices” on its web site that are derived from industry-driven research as well as statistical analysis of thousands of projects in its Benchmarking and Metrics databases. They echo and build on what experienced owner and contractor project managers knew decades ago but had little evidence to prove. They include:

- Advanced Work Packaging

- Alignment

- Benchmarking & Metrics

- Change Management

- Constructability

- Disputes Prevention & Resolution

- Front End Planning

- Lessons Learned

- Materials Management

- Partnering

- Planning for Modularization

- Planning for Startup

- Project Risk Assessment

- Quality Management

- Team Building

- Zero Accidents Techniques

Many of these practices are the owner-driven, and they reflect the persistent centrality of the owner’s role in project success.