9 Construction Planning

9.1 Basic Concepts in the Development of Construction Plans

Construction planning is a fundamental and challenging activity in the management and execution of construction projects. It involves the choice of technology, the definition of work tasks, the estimation of the required resources and durations for individual tasks, and the identification of any interactions among the different work tasks. A good construction plan is the basis for developing the budget and the schedule for work. Developing the construction plan is a critical task in the management of construction, even if the plan is not written or otherwise formally recorded. In addition to these technical aspects of construction planning, it may also be necessary to make organizational decisions about the relationships between project participants and even which organizations to include in a project. For example, the extent to which sub-contractors will be used on a project is often determined during construction planning.

Forming a construction plan is a highly challenging task. As Sherlock Holmes noted:

“Most people, if you describe a train of events to them, will tell you what the result would be. They can put those events together in their minds, and argue from them that something will come to pass. There are few people, however, who, if you told them a result, would be able to evolve from their own inner consciousness what the steps were which led up to that result. This power is what I mean when I talk of reasoning backward.” [1]

Like a detective, a planner begins with a result (i.e. a facility design) and must synthesize the steps required to yield this result. Essential aspects of construction planning include the generation of required activities, analysis of the implications of these activities, and choice among the various alternative means of performing activities. In contrast to a detective discovering a single train of events, however, construction planners also face the normative problem of choosing the best among numerous alternative plans. Moreover, a detective is faced with an observable result, whereas a planner must imagine the final facility as described in the plans and specifications.

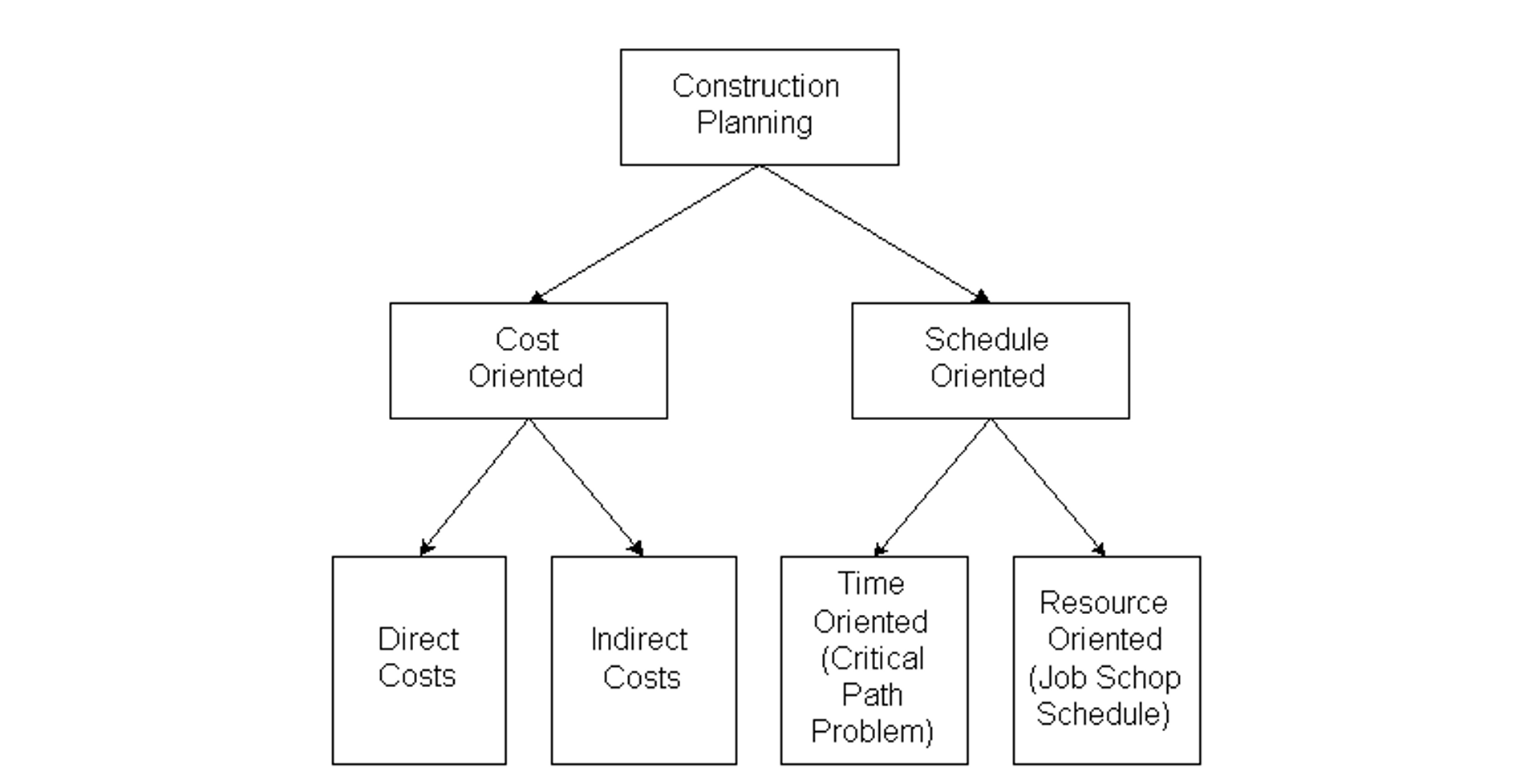

In developing a construction plan, it is common to adopt a primary emphasis on either cost control or on schedule control as illustrated in Fig. 9-1. Some projects are primarily divided into expense categories with associated costs. In these cases, construction planning is cost or expense oriented. Within the categories of expenditure, a distinction is made between costs incurred directly in the performance of an activity and indirectly for the accomplishment of the project. For example, borrowing expenses for project financing and overhead items are commonly treated as indirect costs. For other projects, scheduling of work activities over time is critical and is emphasized in the planning process. In this case, the planner insures that the proper precedences among activities are maintained and that efficient scheduling of the available resources prevails. Traditional scheduling procedures emphasize the maintenance of task precedences (resulting in critical path scheduling procedures) or efficient use of resources over time (resulting in job shop scheduling procedures). Finally, most complex projects require consideration of both cost and scheduling over time, so that planning, monitoring and record keeping must consider both dimensions. In these cases, the integration of schedule and budget information is a major concern.

Figure 9-1 Alternative Emphases in Construction Planning

In this chapter, we shall consider the functional requirements for construction planning such as technology choice, work breakdown, and budgeting. Construction planning is not an activity which is restricted to the period after the award of a contract for construction. It should be an essential activity during the facility design. Also, if problems arise during construction, re-planning is required.

9.2 Choice of Technology and Construction Method

As in the development of appropriate alternatives for facility design, choices of appropriate technology and methods for construction are often ill-structured yet critical ingredients in the success of the project. For example, a decision whether to pump or to transport concrete in buckets will directly affect the cost and duration of tasks involved in building construction. A decision between these two alternatives should consider the relative costs, reliabilities, and availability of equipment for the two transport methods. Unfortunately, the exact implications of different methods depend upon numerous considerations for which information may be sketchy during the planning phase, such as the experience and expertise of workers or the particular underground condition at a site.

In selecting among alternative methods and technologies, it may be necessary to formulate a number of construction plans based on alternative methods or assumptions. Once the full plan is available, then the cost, time and reliability impacts of the alternative approaches can be reviewed. This examination of several alternatives is often made explicit in bidding competitions in which several alternative designs may be proposed or value engineering for alternative construction methods may be permitted. In this case, potential constructors may wish to prepare plans for each alternative design using the suggested construction method as well as to prepare plans for alternative construction methods which would be proposed as part of the value engineering process.

In forming a construction plan, a useful approach is to simulate the construction process either in the imagination of the planner or with a formal computer-based simulation technique. [2] By observing the result, comparisons among different plans or problems with the existing plan can be identified. For example, a decision to use a particular piece of equipment for an operation immediately leads to the question of whether or not there is sufficient access space for the equipment. Three dimensional geometric models in a computer aided design (CAD), building information modeling (BIM), or mixed reality (MR) system may be helpful in simulating space requirements for operations and for identifying any interferences. Similarly, problems in resource availability identified during the simulation of the construction process might be effectively forestalled by providing additional resources as part of the construction plan.

Example 9-1: A roadway rehabilitation

An example from a roadway rehabilitation project in Pittsburgh, PA can serve to illustrate the importance of good construction planning and the effect of technology choice. In this project, the decks on overpass bridges as well as the pavement on the highway itself were to be replaced. The initial construction plan was to work outward from each end of the overpass bridges while the highway surface was replaced below the bridges. As a result, access of equipment and concrete trucks to the overpass bridges was a considerable problem. However, the highway work could be staged so that each overpass bridge was accessible from below at prescribed times. By pumping concrete up to the overpass bridge deck from the highway below, costs were reduced, and the work was accomplished much more quickly.

Example 9-2: Laser Leveling

An example of technology choice is the use of laser leveling equipment to improve the productivity of excavation and grading. [3] Laser levelling screeds for concrete are closely related. In these systems, laser surveying equipment is erected on a site so that the relative height of mobile equipment is known exactly. This height measurement is accomplished by flashing a rotating laser light on a level plane across the construction site and observing exactly where the light shines on receptors on mobile equipment such as graders. Since laser light does not disperse appreciably, the height at which the laser shines anywhere on the construction site gives an accurate indication of the height of a receptor on a piece of mobile equipment. In turn, the receptor height can be used to measure the height of a blade, excavator bucket or other piece of equipment. Combined with electro-hydraulic control systems mounted on mobile equipment such as bulldozers, graders and scrapers, the height of excavation and grading blades can be precisely and automatically controlled in these systems. This automation of blade heights has reduced costs in some cases by over 80% and improved quality in the finished product, as measured by the desired amount of excavation or the extent to which a final grade achieves the desired angle. These systems also permit the use of smaller machines and less skilled operators. However, the use of these semi-automated systems require investments in the laser surveying equipment as well as modification to equipment to permit electronic feedback control units. Still, laser leveling appears to be an excellent technological choice in many instances.

Example 9-3: Prefabrication and modularization

A common construction method choice is whether to assemble parts of a facility on-site or off-site. In the last few decades, an increasing percentage of the work has been planned to be off-site in prefabrication and modularization facilities, typically called “fab shops”. Prefabrication is amenable to lean principles, is typically safer than off-site work, and experiences lower labour costs and fewer weather disruptions. It may however incur higher transportation and materials costs (often balanced out by less waste). Examples include prefabrication of piping assemblies (pipe “spools”), bathroom and kitchen units, equipment skids, and structural subsystems.

9.3 Defining Work Tasks

At the same time that the choice of technology and general method are considered, a parallel step in the planning process is to define the various work tasks that must be accomplished. These work tasks represent the necessary framework to permit scheduling of construction activities, along with estimating the resources required by the individual work tasks, and any necessary precedences or required sequence among the tasks. The terms work “tasks” or “activities” are often used interchangeably in construction plans to refer to specific, defined items of work. In job shop, fab shop, or manufacturing terminology, a project would be called a “job” and an activity called an “operation”, but the sense of the terms is equivalent. [4] The scheduling problem is to determine an appropriate set of activity start times, resource allocations and completion times that will result in completion of the project in a timely and efficient fashion. Construction planning is the necessary forerunner to scheduling. In this planning, defining work tasks, technology and construction method is typically done either simultaneously or in a series of iterations.

The definition of appropriate work tasks can be a laborious and tedious process, yet it represents the necessary information for application of formal scheduling procedures. Since construction projects can involve thousands of individual work tasks, this definition phase can also be expensive and time consuming. Fortunately, many tasks may be repeated in different parts of the facility or past facility construction plans can be used as general models for new projects. For example, the tasks involved in the construction of a building floor may be repeated with only minor differences for each of the floors in the building. Also, standard definitions and nomenclatures for most tasks exist. As a result, the individual planner defining work tasks does not have to approach each facet of the project entirely from scratch.

While repetition of activities in different locations or reproduction of activities from past projects reduces the work involved, there are very few computer aids for the process of defining activities. Databases and information systems can assist in the storage and recall of the activities associated with past projects as described in Chapter 14. For the scheduling process itself, numerous computer programs are available. But for the important task of defining activities, reliance on the skill, judgment and experience of the construction planner is likely to continue.

More formally, an activity is any subdivision of project tasks. The set of activities defined for a project should be comprehensive or completely exhaustive so that all necessary work tasks are included in one or more activities. Typically, each design element in the planned facility will have one or more associated project activities. Execution of an activity requires time and resources, including manpower and equipment, as described in the next section. The time required to perform an activity is called the duration of the activity. The beginning and the end of activities are signposts or milestones, indicating the progress of the project. Occasionally, it is useful to define activities which have no duration to mark important events. For example, receipt of equipment on the construction site may be defined as an activity since other activities would depend upon the equipment availability and the project manager might appreciate formal notice of the arrival. Similarly, receipt of regulatory approvals would also be specially marked in the project plan.

The extent of work involved in any one activity can vary tremendously in construction project plans. Indeed, it is common to begin with fairly coarse definitions of activities and then to further sub-divide tasks as the plan becomes better defined. As a result, the definition of activities evolves during the preparation of the plan. A result of this process is a natural hierarchy of activities with large, abstract functional activities repeatedly sub-divided into more and more specific sub-tasks. For example, the problem of placing concrete on site would have sub-activities associated with placing forms, installing reinforcing steel, pouring concrete, finishing the concrete, removing forms and others. Even more specifically, sub-tasks such as removal and cleaning of forms after concrete placement can be defined. Even further, the sub-task “clean concrete forms” could be subdivided into the various operations:

- Transport forms from on-site storage and unload onto the cleaning station.

- Position forms on the cleaning station.

- Wash forms with water.

- Clean concrete debris from the form’s surface.

- Coat the form surface with an oil release agent for the next use.

- Unload the form from the cleaning station and transport to the storage location.

This detailed task breakdown of the activity “clean concrete forms” would not generally be done in standard construction planning, but it is essential in the process of programming or designing a robot to undertake this activity since the various specific tasks must be well defined for a robot implementation. [5]

It is generally advantageous to introduce an explicit hierarchy of work activities for the purpose of simplifying the presentation and development of a schedule. For example, the initial plan might define a single activity associated with “site clearance.” Later, this single activity might be sub-divided into “re-locating utilities,” “removing vegetation,” “grading”, etc. However, these activities could continue to be identified as sub-activities under the general activity of “site clearance.” This hierarchical structure also facilitates the preparation of summary charts and reports in which detailed operations are combined into aggregate or “super”-activities.

More formally, a hierarchical approach to work task definition decomposes the work activity into component parts in the form of a tree. Higher levels in the tree represent decision nodes or summary activities, while branches in the tree lead to smaller components and work activities. A variety of constraints among the various nodes may be defined or imposed, including precedence relationships among different tasks as defined below. Technology choices may be decomposed to decisions made at particular nodes in the tree. For example, choices on plumbing technology might be made without reference to choices for other functional activities.

Of course, numerous different activity hierarchies can be defined for each construction plan. For example, upper-level activities might be related to facility components such as foundation elements, and then lower-level activity divisions into the required construction operations might be made. Alternatively, upper-level divisions might represent general types of activities such as electrical work, while lower work divisions represent the application of these operations to specific facility components. As a third alternative, initial divisions might represent different spatial locations in the planned facility. The choice of a hierarchy depends upon the desired scheme for summarizing work information and on the convenience of the planner. In computerized databases, multiple hierarchies can be stored so that different aggregations or views of the work breakdown structure can be obtained. In summary, hierarchical breakdowns at each level are driven by:

- Area

- Type of work

- Building systems

The number and detail of the activities in a construction plan is a matter of judgment or convention. Construction plans can easily range between less than a hundred to many thousand defined tasks, depending on the planner’s decisions and the scope of the project. If subdivided activities are too refined, the size of the network becomes unwieldy and the cost of planning excessive. Sub-division yields no benefit if reasonably accurate estimates of activity durations and the required resources cannot be made at the detailed work breakdown level. On the other hand, if the specified activities are too coarse, it is impossible to develop realistic schedules and details of resource requirements during the project. More detailed task definitions permit better control and more realistic scheduling. It is useful to define separate work tasks for:

- those activities which involve different resources, or

- those activities which do not require continuous performance.

For example, the activity “prepare and check shop drawings” should be divided into a task for preparation and a task for checking since different individuals are involved in the two tasks and there may be a time lag between preparation and checking.

In practice, the proper level of detail will depend upon the size, importance and difficulty of the project as well as the specific scheduling and accounting procedures which are adopted. However, it is generally the case that most schedules are prepared with too little detail than too much. It is important to keep in mind that task definition will serve as the basis for scheduling, for communicating the construction plan, and for construction monitoring. Completion of tasks will also often serve as a basis for progress payments from the owner. Thus, more detailed task definitions can be quite useful. But more detailed task breakdowns are only valuable to the extent that the resources required, durations and activity relationships are realistically estimated for each activity. Providing detailed work task breakdowns is not helpful without a commensurate effort to provide realistic resource requirement estimates. As more powerful, automated and AI-based scheduling and monitoring procedures are introduced, the ease of defining and manipulating tasks will increase, and the number of work tasks can reasonably be expected to expand.

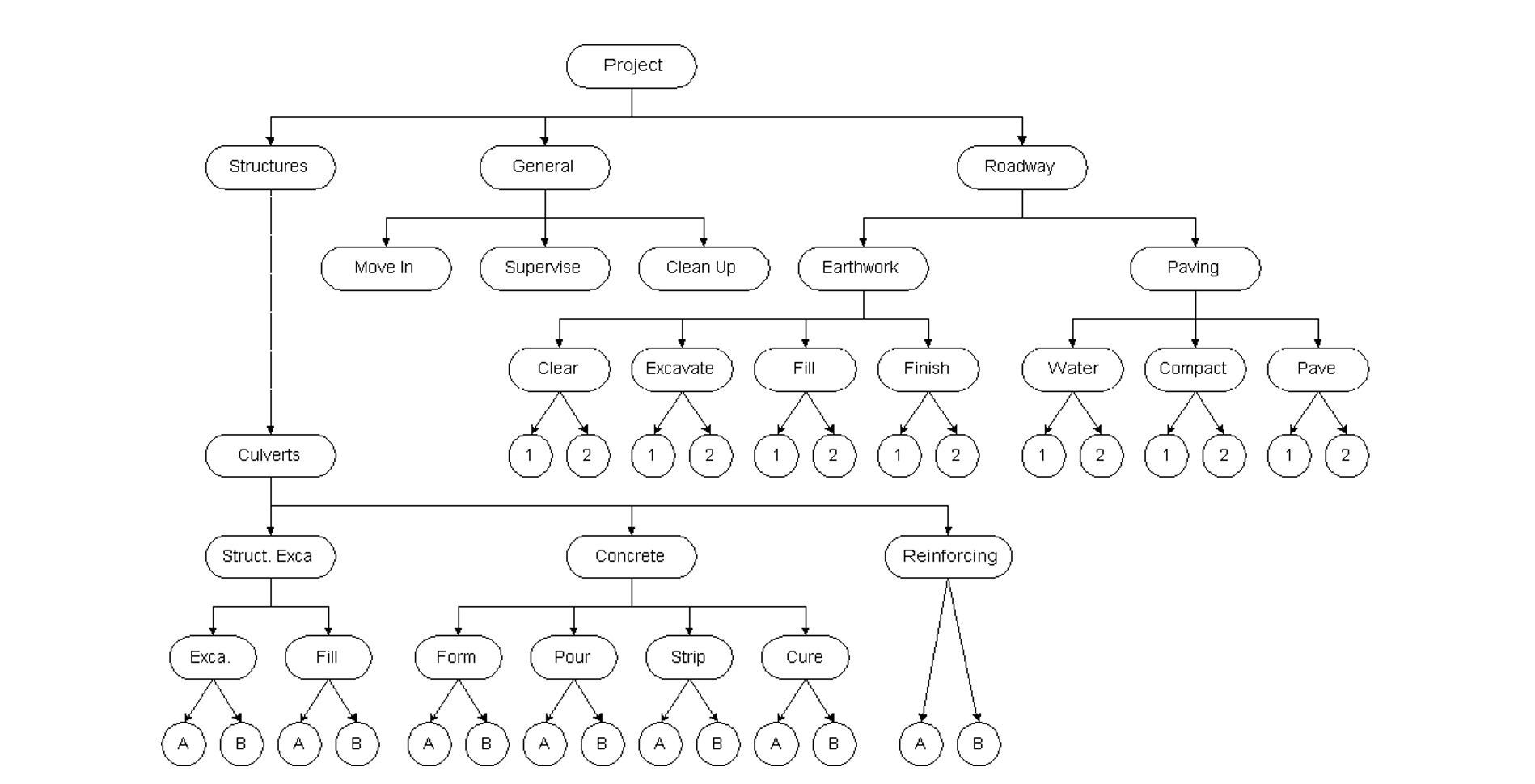

Example 9-3: Task Definition for a Road Building Project

As an example of construction planning, suppose that we wish to develop a plan for a road construction project including two culverts. [6] Initially, we divide project activities into three categories as shown in Figure 9-2: structures, roadway, and general. This division is based on the major types of design elements to be constructed. Within the roadway work, a further sub-division is into earthwork and pavement. Within these subdivisions, we identify clearing, excavation, filling and finishing (including seeding and sodding) associated with earthwork, and we define watering, compaction and paving sub-activities associated with pavement. Finally, we note that the roadway segment is fairly long, and so individual activities can be defined for different physical segments along the roadway path. In Figure 9-2, we divide each paving and earthwork activity into activities specific to each of two roadway segments. For the culvert construction, we define the sub-divisions of structural excavation, concreting, and reinforcing. Even more specifically, structural excavation is divided into excavation itself and the required backfill and compaction. Similarly, concreting is divided into placing concrete forms, pouring concrete, stripping forms, and curing the concrete. As a final step in the structural planning, detailed activities are defined for reinforcing each of the two culverts. General work activities are defined for move in, general supervision, and clean up. As a result of this planning, over thirty different detailed activities have been defined.

At the option of the planner, additional activities might also be defined for this project. For example, materials ordering or lane striping might be included as separate activities. It might also be the case that a planner would define a different hierarchy of work breakdowns than that shown in Figure 9-2. For example, placing reinforcing might have been a sub-activity under concreting for culverts. One reason for separating reinforcement placement might be to emphasize the different material and resources required for this activity. Also, the division into separate roadway segments and culverts might have been introduced early in the hierarchy. With all these potential differences, the important aspect is to ensure that all necessary activities are included somewhere in the final plan.

Figure 9-2 Illustrative Hierarchical Activity Divisions for a Roadway Project

9.4 Defining Precedence Relationships Among Activities

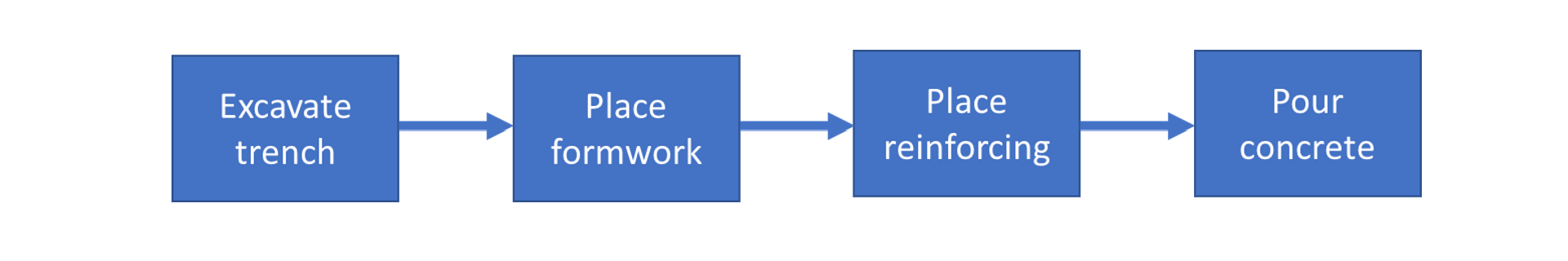

Once work activities have been defined, the relationships among the activities can be specified. Precedence relations between activities signify that the activities must take place in a particular sequence. Numerous natural sequences exist for construction activities due to requirements for structural integrity, regulations, and other technical requirements. For example, design drawings cannot be checked before they are drawn. Diagrammatically, precedence relationships can be illustrated by a network or graph in which the activities are represented by nodes (boxes here) as in Figure 9-0. The arrows in Figure 9-3 are called links in the activity network.

Figure 9-3 Illustrative Set of Four Activities with Precedences

More complicated precedence relationships can also be specified. For example, one activity might not be able to start for several days after the completion of another activity. As a common example, concrete might have to cure (or set) for several days before formwork is removed. This restriction on the removal of forms activity is called a lag between the completion of one activity (i.e., pouring concrete in this case) and the start of another activity (i.e., removing formwork in this case). Most scheduling software permits the use of a variety of precedence relationships.

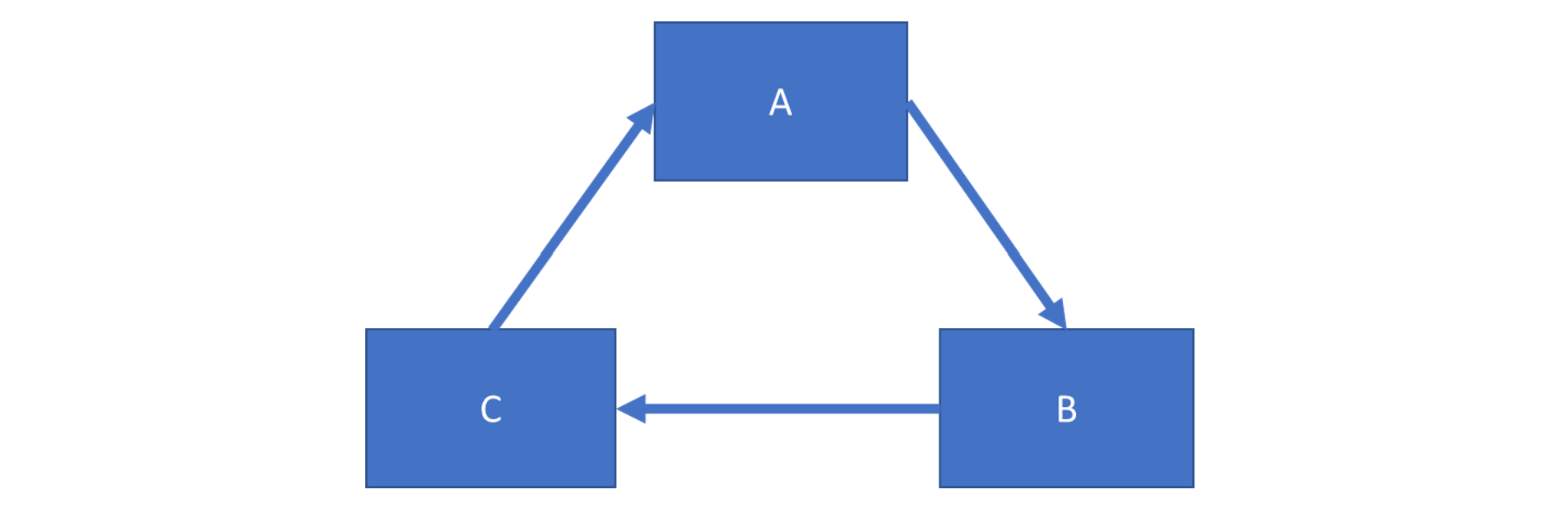

Three mistakes should be avoided in specifying predecessor relationships for construction plans. First, a loop of activity precedences will result in an impossible plan. For example, if activity A precedes activity B, activity B precedes activity C, and activity C precedes activity A, then the project can never be started or completed! Figure 9-4 illustrates the resulting activity network. Fortunately, scheduling software will find any such errors in the logic of the construction plan.

Figure 9-4 Example of an Impossible Work Plan

Forgetting a necessary precedence relationship can be more insidious. For example, suppose that installation of dry wall should be done prior to floor finishing. Ignoring this precedence relationship may result in both activities being scheduled at the same time. Corrections on the spot may result in increased costs or problems of quality in the completed project. Unfortunately, there are few ways in which precedence omissions can be found other than with checks by knowledgeable managers or by comparison to comparable projects. One other possible but little used mechanism for checking precedences is to conduct a physical or computer-based simulation of the construction process and observe any problems. The simulation could be in VR (virtual reality) using a game engine.

Finally, it is important to realize that different types of precedence relationships can be defined and that each has different implications for the schedule of activities:

- Some activities have a necessary technical or physical relationship that cannot be superseded. For example, concrete pours cannot proceed before formwork and reinforcement are in place.

- Some activities have a necessary precedence relationship over a continuous space rather than as discrete work task relationships. For example, formwork may be placed in the first part of an excavation trench even as the excavation equipment continues to work further along in the trench. Formwork placement cannot proceed further than the excavation, but the two activities can be started and stopped independently within this constraint.

- Some “precedence relationships” are not technically necessary but are imposed due to implicit decisions within the construction plan about shared resources. For example, two activities may require the same piece of equipment or same person or the same space, so a precedence relationship might be defined between the two to insure that they are not scheduled for the same time period. Which activity is scheduled first is arbitrary. As a second example, reversing the sequence of two activities may be technically possible but more expensive. In this case, the precedence relationship is not physically necessary but only applied to reduce costs as perceived at the time of scheduling.

In revising schedules as work proceeds, it is important to realize that different types of precedence relationships have quite different implications for the flexibility and cost of changing the construction plan. With all the other responsibilities of a project manager, it is no surprise that preparing or revising the formal, computer-based construction plan is a low priority to a manager in such cases. Nevertheless, formal construction plans may be essential for good management of complicated projects. More importantly, formal planning and scheduling using specified software is commonly contractually obligated by the owner or general contractor.

Example 9-4: Precedence Definition for Site Preparation and Foundation Work

Suppose that a site preparation and concrete slab foundation construction project consists of nine different activities:

-

- Site clearing (of brush and minor debris),

B. Removal of trees,

C. General excavation,

D. Grading general area,

E. Excavation for utility trenches,

F. Placing formwork and reinforcement for concrete,

G. Installing sewer lines,

H. Installing other utilities,

I. Pouring concrete.

- Site clearing (of brush and minor debris),

Activities A (site clearing) and B (tree removal) do not have preceding activities since they depend on none of the other activities. We assume that activities C (general excavation) and D (general grading) are preceded by activity A (site clearing). It might also be the case that the planner wished to delay any excavation until trees were removed, so that B (tree removal) would be a precedent activity to C (general excavation) and D (general grading). Activities E (trench excavation) and F (concrete preparation) cannot begin until the completion of general excavation and tree removal, since they involve subsequent excavation and trench preparation. Activities G (install lines) and H (install utilities) represent installation in the utility trenches and cannot be attempted until the trenches are prepared, so that activity E (trench excavation) is a preceding activity. We also assume that the utilities should not be installed until grading is completed to avoid equipment conflicts, so activity D (general grading) is also preceding activities G (install sewers) and H (install utilities). Finally, activity I (pour concrete) cannot begin until the sewer line is installed and formwork and reinforcement are ready, so activities F and G are preceding. Other utilities may be routed over the slab foundation, so activity H (install utilities) is not necessarily a preceding activity for activity I (pour concrete). The result of our planning are the immediate precedences shown in Table 9-1.

TABLE 9-1 Precedence Relations for a Nine-Activity Project Example

| Activity | Description | Predecessors |

| A B C D E F G H I |

Site clearing Removal of trees General excavation Grading general area Excavation for utility trenches Placing formwork and reinforcement for concrete Installing sewer lines Installing other utilities Pouring concrete |

— — A A B,C B,C D,E D,E F,G |

With this information, the next problem is to represent the activities in a network diagram and to determine all the precedence relationships among the activities. Typically, the nine activities are represented by nodes and predecessor relationships by branches or links, as in Figure 9-5. The result is an activity-on-node diagram. In Figure 9-5, new activity nodes representing the beginning and the end of construction have been added to mark these important milestones. In planning, scheduling and project management software, the activity-on-node representation is standard, however it is even more common to see something called a time-scaled-logic-diagram. Variations on these representations and the old Gantt chart method exist as well for special purposes. These representations will be discussed in the next chapter.

Figure 9-5 Activity-on-Node Representation of a Nine Activity Project

It is also notable that Table 9-1 lists only the immediate predecessor relationships. Clearly, there are other precedence relationships which involve more than one activity. For example, “installing sewer lines” (activity G) cannot be undertaken before “site clearing” (Activity A) is complete since the activity “grading general area” (Activity D) must precede activity G and must follow activity A. Table 9-1 is an implicit precedence list since only immediate predecessors are recorded. An explicit predecessor list would include all of the preceding activities for activity G. Table 9-2 shows all such predecessor relationships implied by the project plan. This table can be produced by tracing all paths through the network back from a particular activity and can be performed algorithmically. [7] For example, inspecting Figure 9-6 reveals that each activity except for activity B depends upon the completion of activity A.

TABLE 9-2 All Activity Precedence Relationships for a Nine-Activity Project

| Predecessor Activity | Direct Successor Activities | All Successor Activities | All Predecessor Activities |

| A B C D E F G H I |

C,D E,F E,F G,H G,H I I — — |

E,F,G,H,I G,H,I G,H,I I I — — — — |

— — A A A,B,C A,B,C A,B,C,D,E A,B,C,D,E A,B,C,D,E,F,G |

9.5 Estimating Activity Durations

In most scheduling procedures, each work activity has an associated time duration. These durations are used extensively in preparing a schedule. For example, suppose that the durations shown in Table 9-3 were estimated for the project diagrammed in Figure 9-0. The entire set of activities would then require at least 3 days, since the activities follow one another directly and require a total of 1.0 + 0.5 + 0.5 + 1.0 = 3 days. If another activity proceeded in parallel with this sequence, the 3-day minimum duration of these four activities is unaffected. More than 3 days would be required for the sequence if there was a delay or a lag between the completion of one activity and the start of another.

TABLE 9-3 Durations and Predecessors for a Four Activity Project Illustration

| Activity | Predecessor | Duration (Days) |

| Excavate trench Place formwork Place reinforcing Pour concrete |

— Excavate trench Place formwork Place reinforcing |

1.0 |

All formal scheduling procedures rely upon estimates of the durations of the various project activities as well as the definitions of the predecessor relationships among tasks. The variability of an activity’s duration may also be considered. Formally, the probability distribution of an activity’s duration as well as the expected or most likely duration may be used in scheduling. A probability distribution indicates the chance that a particular activity duration will occur. In advance of actually doing a particular task, we cannot be certain exactly how long the task will require.

A straightforward approach to the estimation of activity durations is to keep historical records of particular activities and rely on the average durations from this experience in making new duration estimates. Since the scope of activities are unlikely to be identical between different projects, unit productivity rates are typically employed for this purpose. For example, the duration of an activity Dij such as concrete formwork assembly might be estimated as:

where Aij is the required formwork area to assemble (in square yards), Pij is the average productivity of a standard crew in this task (measured in square yards per hour), and Nij is the number of crews assigned to the task. In some organizations, unit production time, Tij, is defined as the time required to complete a unit of work by a standard crew (measured in hours per square yards) is used as a productivity measure such that Tij is a reciprocal of Pij.

A formula such as Eq. (9.1) can be used for nearly all construction activities. Typically, the required quantity of work, Aij is determined from detailed examination of the final facility design. This quantity-take-off to obtain the required amounts of materials, volumes, and areas is a very common process in bid preparation by contractors. In some countries, specialized quantity surveyors provide the information on required quantities for all potential contractors and the owner. The number of crews working, Nij, is decided by the planner. In many cases, the number or amount of resources applied to particular activities may be modified in light of the resulting project plan and schedule. Finally, some estimate of the expected work productivity, Pij must be provided to apply Equation (9.1). As with cost factors, commercial services can provide average productivity figures for many standard activities of this sort. Historical records in a firm can also provide data for estimation of productivities.

The calculation of a duration as in Equation (9.1) is only an approximation to the actual activity duration for a number of reasons. First, it is usually the case that peculiarities of the project make the accomplishment of a particular activity more or less difficult. For example, access to the forms in a particular location may be difficult; as a result, the productivity of assembling forms may be lower than the average value for a particular project. Often, adjustments based on engineering judgment are made to the calculated durations from Equation (9.1) for this reason.

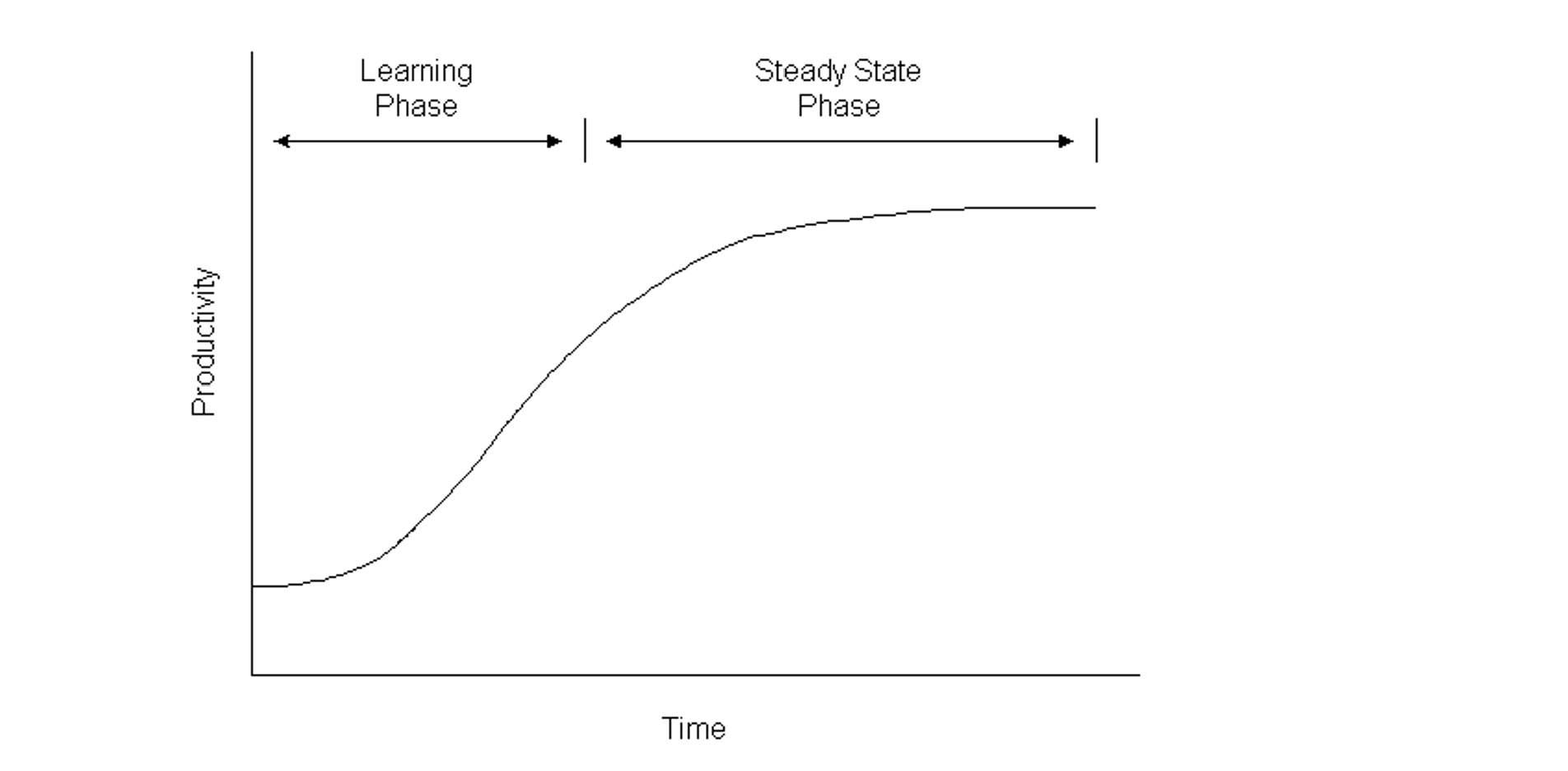

In addition, productivity rates may vary in both systematic and random fashions from the average. An example of systematic variation is the effect of learning on productivity. As a crew becomes familiar with an activity and the work habits of the crew, their productivity will typically improve. Figure 9-6 illustrates the type of productivity increase that might occur with experience; this curve is called a learning curve. The result is that productivity Pij is a function of the duration of an activity or project. A common construction example is that the assembly of floors in a building might go faster at higher levels due to improved productivity even though the transportation time up to the active construction area is longer. Again, historical records or subjective adjustments might be made to represent learning curve variations in average productivity. [8]

Figure 9-6 Illustration of Productivity Changes Due to Learning

Random factors will also influence productivity rates and make estimation of activity durations uncertain. For example, a scheduler will typically not know at the time of making the initial schedule how skillful the crew and manager will be that are assigned to a particular project. The productivity of a skilled designer may be many times that of an unskilled engineer. In the absence of specific knowledge, the estimator can only use average values of productivity.

Weather effects are often very important and thus deserve particular attention in estimating durations. Weather has both systematic and random influences on activity durations. Whether or not a rainstorm will come on a particular day is certainly a random effect that will influence the productivity of many activities. However, the likelihood of a rainstorm is likely to vary systematically from one month or one site to the next. Adjustment factors for inclement weather as well as meteorological records can be used to incorporate the effects of weather on durations. As a simple example, an activity might require ten days in perfect weather, but the activity could not proceed in the rain. Furthermore, suppose that rain is expected ten percent of the days in a particular month. In this case, the expected activity duration is eleven days including one expected rain day.

Finally, the use of average productivity factors themselves cause problems in the calculation presented in Equation (9.1). The expected value of the multiplicative reciprocal of a variable is not exactly equal to the reciprocal of the variable’s expected value. For example, if productivity on an activity is either six in good weather (ie., P=6) or two in bad weather (ie., P=2) and good or bad weather is equally likely, then the expected productivity is P = (6)(0.5) + (2)(0.5) = 4, and the reciprocal of expected productivity is 1/4. However, the expected reciprocal of productivity is E[1/P] = (0.5)/6 + (0.5)/2 = 1/3. The reciprocal of expected productivity is 25% less than the expected value of the reciprocal in this case! By representing only two possible productivity values, this example represents an extreme case, but it is always true that the use of average productivity factors in Equation (9.1) will result in optimistic estimates of activity durations. The use of actual averages for the reciprocals of productivity or small adjustment factors may be used to correct for this non-linearity problem.

The simple duration calculation shown in Equation (9.1) also assumes an inverse linear relationship between the number of crews assigned to an activity and the total duration of work. While this is a reasonable assumption in situations for which crews can work independently and require no special coordination, it need not always be true. For example, design tasks may be divided among numerous architects and engineers, but delays to insure proper coordination and communication increase as the number of workers increase. As another example, insuring a smooth flow of material to all crews on a site may be increasingly difficult as the number of crews increase. In these latter cases, the relationship between activity duration and the number of crews is unlikely to be inversely proportional as shown in Equation (9.1). As a result, adjustments to the estimated productivity from Equation (9.1) must be made. Alternatively, more complicated functional relationships might be estimated between duration and resources used in the same way that nonlinear preliminary or conceptual cost estimate models are prepared.

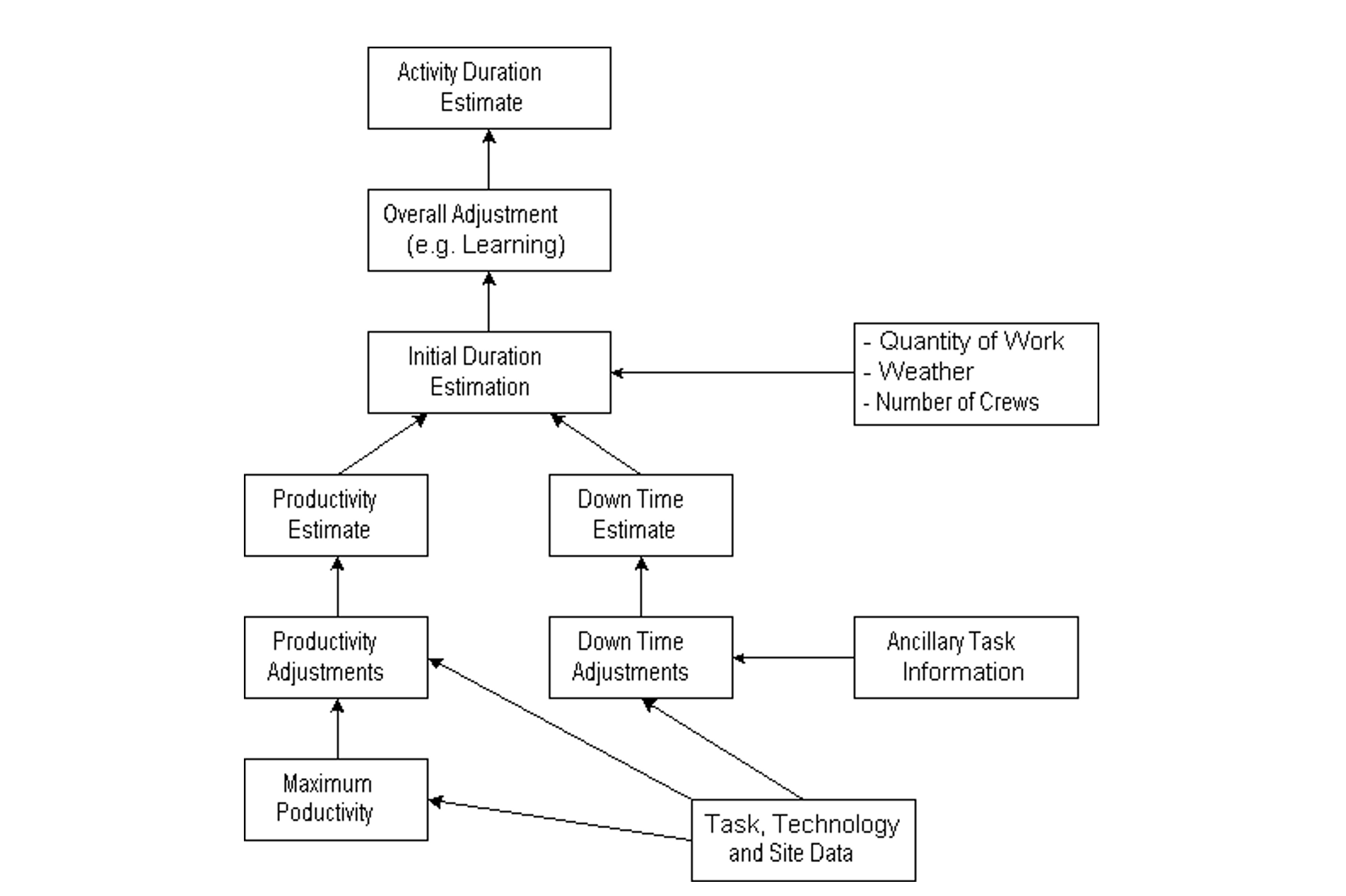

One mechanism to formalize the estimation of activity durations is to employ a hierarchical estimation framework. This approach decomposes the estimation problem into component parts in which the higher levels in the hierarchy represent attributes which depend upon the details of lower-level adjustments and calculations. For example, Figure 9-8 represents various levels in the estimation of the duration of masonry construction. [9] At the lowest level, the maximum productivity for the activity is estimated based upon general work conditions. Table 9-4 illustrates some possible maximum productivity values that might be employed in this estimation. At the next higher level, adjustments to these maximum productivities are made to account for special site conditions and crew compositions; table 9-5 illustrates some possible adjustment rules. At the highest level, adjustments for overall effects such as weather are introduced. Also shown in Figure 9-7 are nodes to estimate down or unproductive time associated with the masonry construction activity. The formalization of the estimation process illustrated in Figure 9-8 permits the development of computer aids for the estimation process or can serve as a conceptual framework for a human estimator.

TABLE 9-4 Maximum Productivity Estimates for Masonry Work

| Masonry unit size | Condition(s) | Maximum productivity achievable |

| 8 inch block | None | 400 units/day/mason |

| 6 inch | Wall is “long” | 430 units/day/mason |

| 6 inch | Wall is not “long” | 370 units/day/mason |

| 12 inch | Labor is non-union | 300 units/day/mason |

| 4 inch | Wall is “long” Weather is “warm and dry” or high-strength mortar is used |

480 units/day/mason |

| 4 inch | Wall is not “long” Weather is “warm and dry” or high-strength mortar is used |

430 units/day/mason |

| 4 inch | Wall is “long” Weather is not “warm and dry” or high-strength mortar is not used |

370 units/day/mason |

| 4 inch | Wall is not “long” Weather is not “warm and dry” or high-strength mortar is not used |

320 units/day/mason |

| 8 inch | There is support from existing wall | 1,000 units/day/mason |

| 8 inch | There is no support from existing wall | 750 units/day/mason |

| 12 inch | There is support from existing wall | 700 units/day/mason |

| 12 inch | There is no support from existing wall | 550 |

TABLE 9-5 Possible Adjustments to Maximum Productivities for Masonry Construction

| Impact | Condition(s) | Adjustment magnitude (% of maximum) |

| Crew type | Crew type is non-union Job is “large” |

15% |

| Crew type | Crew type is union Job is “small” |

10% |

| Supporting labor | There are less than two laborers per crew | 20% |

| Supporting labor | There are more than two masons/laborers | 10% |

| Elevation | Steel frame building with masonry exterior wall has “insufficient” support labor |

10% |

| Elevation | Solid masonry building with work on exterior uses non-union labor | 12% |

| Visibility | block is not covered | 7% |

| Temperature | Temperature is below 45o F | 15% |

| Temperature | Temperature is above 45o F | 10% |

| Brick texture | bricks are baked high Weather is cold or moist |

10% |

Figure 9-7 A Hierarchical Estimation Framework for Masonry Construction

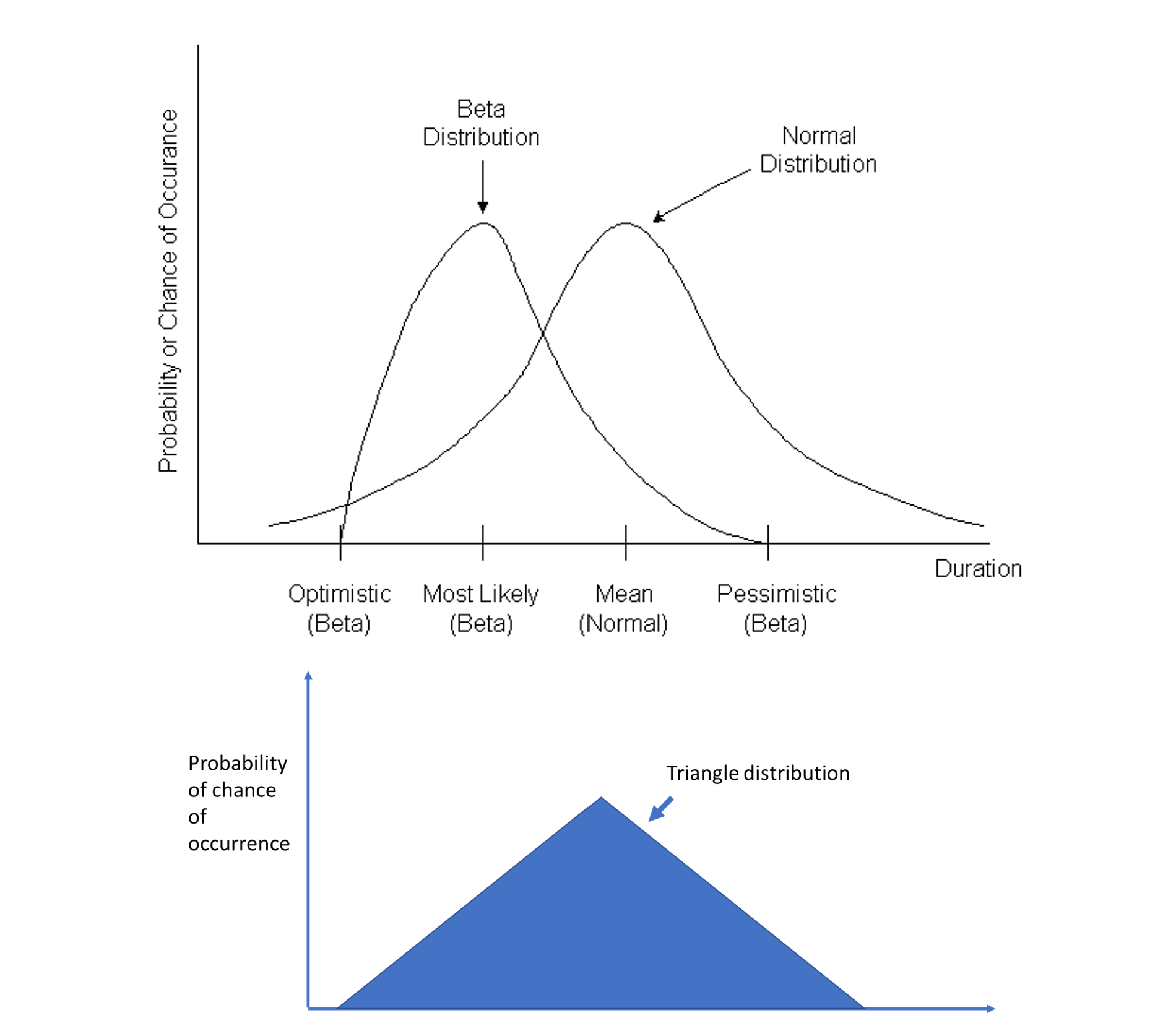

In addition to the problem of estimating the expected duration of an activity, some scheduling procedures explicitly consider the uncertainty in activity duration estimates by using the probabilistic distribution of activity durations. That is, the duration of a particular activity is assumed to be a random variable that is distributed in a particular fashion. For example, an activity duration might be assumed to be distributed as a normal or a beta distributed random variable as illustrated in Figure 9-8. This figure shows the probability or chance of experiencing a particular activity duration based on a probabilistic distribution. The beta distribution is often used to characterize activity durations, since it can have an absolute minimum and an absolute maximum of possible duration times. The normal distribution is a good approximation to the beta distribution in the center of the distribution and is easy to work with, so it is often used as an approximation. Most commonly, a triangle probability distribution is used in practice, because not enough data exists to fit a functional form. Like Beta, the triangle distribution uses: (1) optimistic, (2) most likely, and (3) pessimistic.

Figure 9-8 Beta, Normally and Triangle Distributed Activity Durations

If a standard random variable is used to characterize the distribution of activity durations, then only a few parameters are required to calculate the probability of any particular duration. Still, the estimation problem is increased considerably since more than one parameter is required to characterize most of the probabilistic distribution used to represent activity durations. For the beta distribution, three or four parameters are required depending on its generality, whereas the normal distribution requires two parameters.

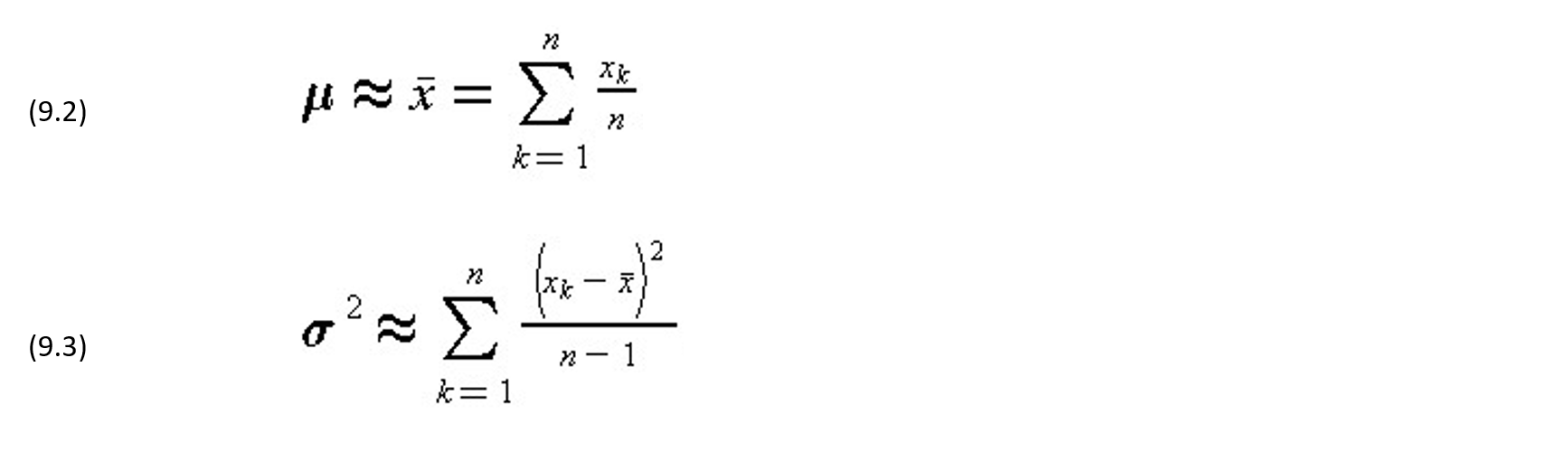

As an example, the normal distribution is characterized by two parameters, and representing the average duration and the standard deviation of the duration, respectively. Alternatively, the variance of the distribution could be used to describe or characterize the variability of duration times; the variance is the value of the standard deviation multiplied by itself. From historical data, these two parameters can be estimated as:

where we assume that n different observations xk of the random variable x are available. This estimation process might be applied to activity durations directly (so that xk would be a record of an activity duration Dij on a past project) or to the estimation of the distribution of productivities (so that xk would be a record of the productivity in an activity Pi) on a past project) which, in turn, is used to estimate durations using Equation (9.4). If more accuracy is desired, the estimation equations for mean and standard deviation, Equations (9.2) and (9.3) would be used to estimate the mean and standard deviation of the reciprocal of productivity to avoid non-linear effects. Using estimates of productivities, the standard deviation of activity duration would be calculated as:

where σij is the estimated standard deviation of the reciprocal of productivity that is calculated from Equation (9.3) by substituting 1/P for x.

9.6 Estimating Resource Requirements for Work Activities

In addition to precedence relationships and time durations, resource requirements are usually estimated for each activity. Since the work activities defined for a project are comprehensive, the total resources required for the project are the sum of the resources required for the various activities. By making resource requirement estimates for each activity, the requirements for particular resources during the course of the project can be identified. Potential bottlenecks can thus be identified, and schedule, resource allocation or technology changes made to avoid problems.

Many formal scheduling procedures can incorporate constraints imposed by the availability of particular resources. For example, the unavailability of a specific piece of equipment or crew may prohibit activities from being undertaken at a particular time. Another type of resource is space. A planner typically will schedule only one activity in the same location at the same time. While activities requiring the same space may have no necessary technical precedence, simultaneous work might not be possible. Computational procedures for these various scheduling problems will be described in Chapters 10 and 11. In this section, we shall discuss the estimation of required resources.

The initial problem in estimating resource requirements is to decide the extent and number of resources that might be defined. At a very aggregate level, resources categories might be limited to the amount of labor (measured in man-hours or in dollars), the amount of materials required for an activity, the amount of equipment required, and the total cost of the activity. At this aggregate level, the resource estimates may be useful for purposes of project monitoring and cash flow planning. For example, actual expenditures on an activity can be compared with the estimated required resources to reveal any problems that are being encountered during the course of a project. Monitoring procedures of this sort are described in Chapter 12. However, this aggregate definition of resource use would not reveal bottlenecks associated with particular types of equipment or workers.

More detailed definitions of required resources would include the number and type of both workers and equipment required by an activity as well as the amount and types of materials. Standard resource requirements for particular activities can be recorded and adjusted for the special conditions of particular projects. As a result, the resources types required for particular activities may already be defined. Reliance on historical or standard activity definitions of this type requires a standard coding system for activities.

In making adjustments for the resources required by a particular activity, most of the problems encountered in forming duration estimations described in the previous section are also present. In particular, resources such as labor requirements will vary in proportion to the work productivity, Pij, used to estimate activity durations in Equation (9.1). Mathematically, a typical estimating equation would be:

where Rkij are the resources of type k required by activity ij, Dij is the duration of activity ij, Nij is the number of standard crews allocated to activity ij, and Ukij is the amount of resource type k used per standard crew. For example, if an activity required eight hours with two crews assigned and each crew required three workers, the effort would be R = 8*2*3 = 48 labor-hours.

From the planning perspective, the important decisions in estimating resource requirements are to determine the type of technology and equipment to employ and the number of crews to allocate to each task. Clearly, assigning additional crews might result in faster completion of a particular activity. However, additional crews might result in congestion and coordination problems, so that work productivity might decline. Further, completing a particular activity earlier might not result in earlier completion of the entire project, as discussed in Chapter 10.

Example 9-5: Resource Requirements for Block Foundations

In placing concrete block foundation walls, a typical crew would consist of three bricklayers and two bricklayer helpers. If sufficient space was available on the site, several crews could work on the same job at the same time, thereby speeding up completion of the activity in proportion to the number of crews. In more restricted sites, multiple crews might interfere with one another. For special considerations such as complicated scaffolding or large blocks (such as twelve-inch block), a bricklayer helper for each bricklayer might be required to insure smooth and productive work. In general, standard crew composition depends upon the specific construction task and the equipment or technology employed. These standard crews are then adjusted in response to special characteristics of a particular site.

Example 9-6: Pouring Concrete Slabs

For large concrete pours on horizontal slabs, it is important to plan the activity so that the slab for a full block can be completed continuously in a single day. Resources required for pouring the concrete depend upon the technology used. For example, a standard crew for pumping concrete to the slab might include a foreman, five laborers, one finisher, and one equipment operator. Related equipment would be vibrators and the concrete pump itself. For delivering concrete with a chute directly from the delivery truck, the standard crew might consist of a foreman, four laborers and a finisher. The number of crews would be chosen to ensure that the desired amount of concrete could be placed in a single day. In addition to the resources involved in the actual placement, it would also be necessary to insure a sufficient number of delivery trucks and availability of the concrete itself.

9.7 Coding Systems

One objective in many construction planning efforts is to define the plan within the constraints of a universal coding system for identifying activities. Each activity defined for a project would be identified by a pre-defined code specific to that activity. The use of a common nomenclature or identification system is basically motivated by the desire for better integration of organizational efforts and improved information flow. In particular, coding systems are adopted to provide a numbering system to replace verbal descriptions of items. These codes reduce the length or complexity of the information to be recorded. A common coding system within an organization also aids consistency in definitions and categories between projects and among the various parties involved in a project. Common coding systems also aid in the retrieval of historical records of cost, productivity and duration on particular activities. Finally, electronic data storage and retrieval operations are much more efficient with standard coding systems, as described in Chapter 14.

In North America, the most widely used standard coding system for constructed facilities is the MASTERFORMAT system developed by the Construction Specifications Institute (CSI) of the United States and Construction Specifications of Canada. [10] After development of separate systems, this combined system was originally introduced as the Uniform Construction Index (UCI) in 1972 and was subsequently adopted for use by numerous firms, information providers, professional societies and trade organizations. The term MASTERFORMAT was introduced with the 1978 revision of the UCI codes. MASTERFORMAT provides a standard identification code for nearly all the elements associated with building construction. This code can be purchased from CSI or accessed in local university libraries. Old versions are sometimes shared online.

MASTERFORMAT involves a hierarchical coding system with multiple levels plus keyword text descriptions of each item. In the numerical coding system, the first two digits represent one of the 49 potential divisions for work; in 2024, 35 divisions were actively defined. In the latest versions of the MASTERFORMAT, four additional digits indicate subdivisions within each division. For example, the code 26 09 17, is defined as within Specifications Group, Facility Service Subgroup, Division Electrical. Specifically, it is for Division 26 (Electrical) and Section 09 (Instrumentation and Control for Electrical Systems) and sub-section (Programmable Controllers). The major divisions in the MASTERFORMAT system are shown in Table 9-6.

TABLE 9-6 Major Divisions in the Uniform Construction Index

| PROCUREMENT AND CONTRACTING REQUIREMENTS GROUP

Division 00 – Procurement and Contracting Requirements Introductory Information Procurement Requirements Contracting Requirements

SPECIFICATIONS GROUP

GENERAL REQUIREMENTS SUBGROUP Division 01 – General Requirements

FACILITY CONSTRUCTION SUBGROUP Division 02 – Existing Conditions Division 03 – Concrete Division 04 – Masonry Division 05 – Metals Division 06 – Wood, Plastics, and Composites Division 07 – Thermal and Moisture Protection Division 08 – Openings Division 09 – Finishes Division 10 – Specialties Division 11 – Equipment Division 12 – Furnishings Division 13 – Special Construction Division 14 – Conveying Equipment |

FACILITY SERVICES SUBGROUP

Division 21 – Fire Suppression Division 22 – Plumbing Division 23 – Heating, Ventilating, and Air Conditioning (HVAC) Division 25 – Integrated Automation Division 26 – Electrical Division 27 – Communications Division 28 – Electronic Safety and Security

SITE AND INFRASTRUCTURE SUBGROUP Division 31 – Earthwork Division 32 – Exterior Improvements Division 33 – Utilities Division 34 – Transportation Division 35 – Waterway and Marine Construction

PROCESS EQUIPMENT SUBGROUP Division 40 – Process Interconnections Division 41 – Material Processing and Handling Equipment Division 42 – Process Heating, Cooling, and Drying Equipment Division 43 – Process Gas and Liquid Handling, Purification, and Storage Equipment Division 44 – Pollution and Waste Control Equipment Division 45 – Industry-Specific Manufacturing Equipment Division 46 – Water and Wastewater Equipment Division 48 – Electrical Power Generation |

While MASTERFORMAT provides a very useful means of organizing and communicating information, it has some obvious limitations as a complete project coding system. First, more specific information such as location of work or responsible organization might be required for project cost control. Code extensions are sometimes added in addition to the digits in the basic MASTERFORMAT codes. For example, a typical extended code might have the following elements:

0534.31.23.16.16.21.A.00.cf34

The first four digits indicate the project for this activity; this code refers to an activity on project number 0534. The next eight digits refer to the MASTERFORMAT subsection, “Structural Excavation for Minor Structures” within Division 31 – Earthwork, section 23 Excavation and Fill. The next two digits refer to specific activities defined within this MASTERFORMAT-based code; the digits 21 in this example might refer to excavation of column footings. The next character refers to the block or general area on the site that the activity will take place; in this case, block A is indicated. The digits 00 could be replaced by a code to indicate the responsible organization for the activity. Finally, the characters cf34 refer to the particular design element number for which this excavation is intended; in this case, column footing number 34 is intended. Thus, this activity is to perform the excavation for column footing number 34 in block A on the site. Note that a number of additional activities would be associated with column footing 34, including formwork and concreting. Additional fields in the coding systems might also be added to indicate the responsible crew for this activity or to identify the specific location of the activity on the site (defined, for example, as x, y and z coordinates with respect to a base point).

In practice, many organizations retain and use internal and proprietary “codes of accounts” or “cost codes”. In fact, if the organization is a construction firm that has been formed over time through the amalgamation of more than one company, which is not uncommon in the industry, the divisions formed in the amalgamated company that correspond to the original separate companies typically will perpetuate their historical internal cost codes. There are good reasons for this. Historical data for estimating is stored in the old codes; internal software systems and documentation use the old codes; and the codes may still work for the type of work the corporate division is focused on. Nevertheless, this disparity in coding systems across the industry has been a major barrier within and among companies that wish to develop productivity improvement systems, which attempt to correlate project practices with productivity performance (using what are called benchmarking and metrics systems), because the data cannot easily be aggregated for analysis across organizational divisions. This remains a major impediment to productivity improvement in the industry.

Thus, in devising organizational codes for project activities, there is a continual tension between adopting systems that are convenient or expedient for one project or for one project manager or one division and systems appropriate for an entire organization or an industry sector. As a general rule, the record-keeping and communication advantages of standard systems are excellent arguments for their adoption. Even in small projects, however, ad hoc or haphazard coding systems can lead to problems as the system is revised and extended over time.

9.8 References

- Baracco-Miller, E., “Planning for Construction,” Unpublished MS Thesis, Dept. of Civil Engineering, Carnegie Mellon University, 1987.

- Construction Specifications Institute, MASTERFORMAT – Master List of Section Titles and Numbers, Releasing Industry Group, Alexandria, VA, 1983.

- Jackson, M.J. Computers in Construction Planning and Control, Allen & Unwin, London, 1986.

- Sacerdoti, E.D. A Structure for Plans and Behavior, Elsevier North-Holland, New York, 1977.

- Zozaya-Gorostiza, C., “An Expert System for Construction Project Planning,” Unpublished PhD Dissertation, Dept. of Civil Engineering, Carnegie Mellon University, 1988.

9.9 Problems

(1) Develop an alternative work breakdown for the activities shown in Figure 9-2 (Example 9-3). Begin first with a spatial division on the site (i.e. by roadway segment and structure number), and then include functional divisions to develop a different hierarchy of activities.

(2) Consider an emergency structure built by inflating a special hemispherical rubber tent, spraying shotcrete on the tent, letting it cure, and then deflating and removing the tent. Develop a work breakdown for this structure, precedence relationships, and estimate the required resources. Assume that the tent is twenty feet in diameter by eight feet tall.

(3) Develop a work breakdown and activity network for the project of designing a cell communications tower.

(4) Select a vacant site in your vicinity and define the various activities and precedences among these activities that would be required to prepare the site for the placement of pre-fabricated residences. Use the coding system for Earthwork found in MASTERFORMAT to label these activities.

(5) Develop precedence relationships for the roadway project activities appearing in Figure 9-2 (Example 9-3).

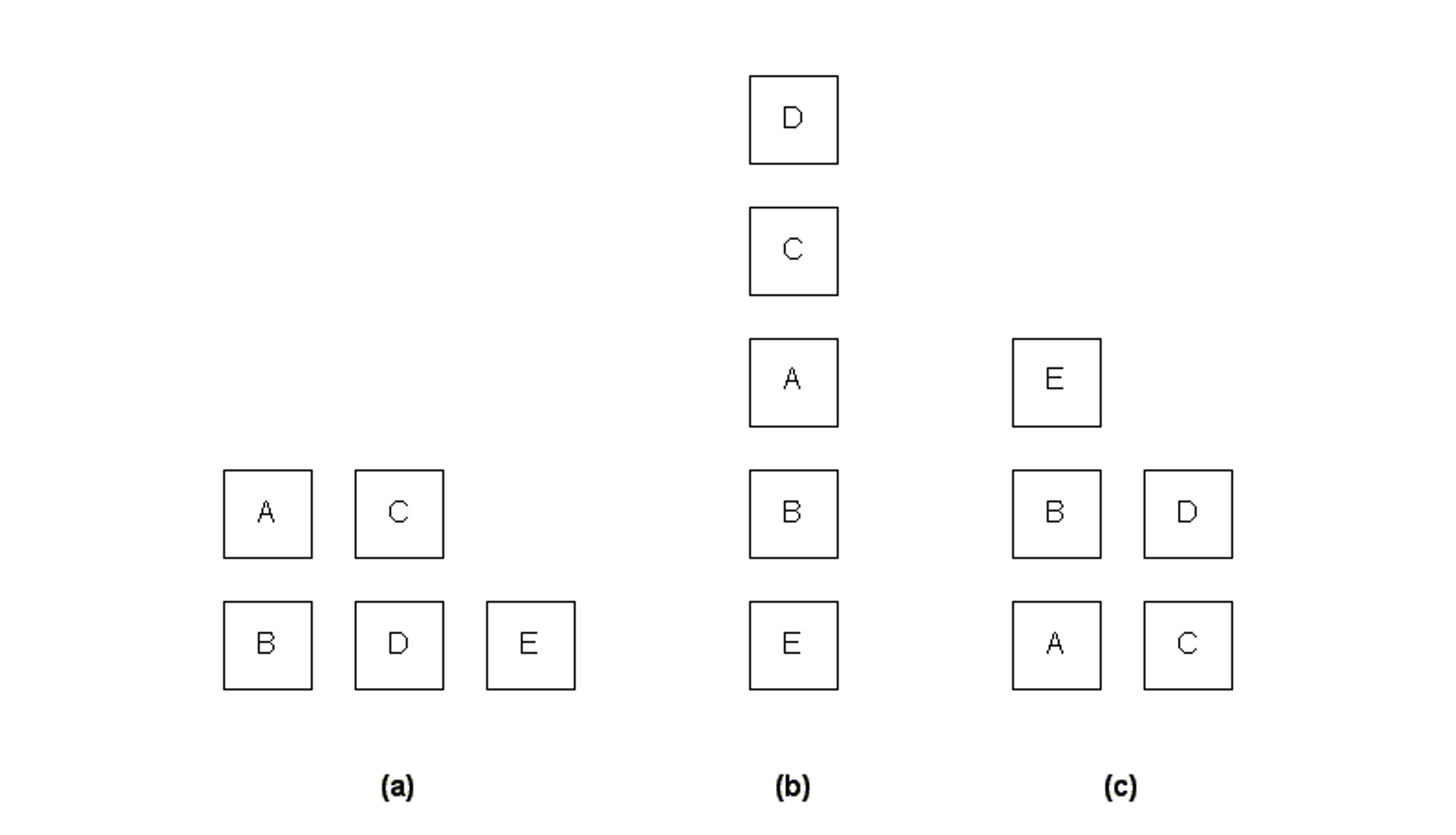

(6) Suppose that you have a construction robot capable of performing two tasks in manipulating stacked materials pallets on a construction site:

- PLACE PALLET X ON PALLET Y: This action places the pallet x on top of the pallet y. Preconditions for applying this action are that both pallet x and pallet y have clear tops (so there is no pallet on top of x or y). The robot will automatically locate the specified pallet using AI-based computer vision as well as identification and interpretation of QR or bar codes.

- CLEAR PALLET X: This action removes any pallet from the top of pallet x. A necessary precondition for this action is that pallet x has one and only one pallet on top. The pallet removed is placed on the ground in a clear location.

For this robot, answer the following questions:

- Using only the two robot actions, specify a sequence of robot actions to take the five pallets shown in Figure 9-9(a) to the position shown in Figure 9-9(b) in five or six robot actions.

- Specify a sequence of robot actions to move the pallets from position (b) to position (c) in Figure 9-9 in six moves.

- Develop an activity network for the robot actions in moving from position (b) to position (c) in Figure 9-9. Prepare activity-on-node representations. Are there alternative sequences of activities that the robot might perform to accomplish the desired position?

Figure 9-9 Illustrative Pallet Positions for Construction Robot Motion Planning

(7) In the previous problem, suppose that switching from the PLACE PALLET action to the CLEAR PALLET action or vice versa requires an extra ten seconds. Movements themselves require 8 seconds. What is the sequence of actions of shortest duration to go from position (b) to position (a) in Figure 9-9?

(8) Repeat Problem 6 above for the movement from position (a) to position (c) in Figure 9-9.

(9) Repeat Problem 7 above for the movement from position (a) to position (c) in Figure 9-9.

(10) Suppose that you have an enhanced robot with two additional commands capabilities:

- CARRY PALLETS X-Y to PALLETS Z: This action moves pallets X-Y to the top of pallet Z. Pallets X-Y may involve any number of pallets as long as X is on the bottom and Y is on the top. This move assumes that Z has a clear top.

- CLEAR ALL PALLETS X TO PALLETS Z: This action moves all pallets on top of pallet X to the top of pallet Z. If a pallet Z is not specified, then the pallets are moved to a clear location on site.

How do these capabilities change your answer to Problems 6 and 7?

(11) How does the additional capability described in Problem 10 change your answer to Problems 8 and 9?

9.10 Footnotes

- A.C. Doyle, “A Study in Scarlet,” The Complete Sherlock Holmes, Doubleday & Co., pg. 83, 1930. Back

- See, for example, Paulson, B.C., S.A. Douglas, A. Kalk, A. Touran and G.A. Victor, “Simulation and Analysis of Construction Operations,” ASCE Journal of Technical Topics in Civil Engineering, 109(2), August, 1983, pp. 89, or Carr, R.I., “Simulation of Construction Project Duration,” ASCE Journal of the Construction Division,105(2), June 1979, 117-128. Back

- For a description of a laser leveling system, see Paulson, B.C., Jr., “Automation and Robotics for Construction,” ASCE Journal of Construction Engineering and Management, (111)3, pp. 190-207, Sept. 1985. Back

- See Baker, K.R., Introduction to Sequencing and Scheduling, John-Wiley and Sons, New York, 1974, for an introduction to scheduling in manufacturing. Back

- See Skibniewski, M.J. and C.T. Hendrickson, “Evaluation Method for Robotics Implementation: Application to Concrete Form Cleaning,” Proc. Second Intl. Conf. on Robotics in Construction, Carnegie-Mellon University, Pittsburgh, PA., 1985, for more detail on the work process design of a concrete form cleaning robot. Back

- This example is adapted from Aras, R. and J. Surkis, “PERT and CPM Techniques in Project Management,” ASCE Journal of the Construction Division,Vol. 90, No. CO1, March, 1964. Back

- For a discussion of network reachability and connectivity computational algorithms, see Chapters 2 and 7 in N. Christofides, Graph Theory: An Algorithmic Approach, London: Academic Press, 1975, or any other text on graph theory. Back

- See H.R. Thomas, C.T. Matthews and J.G. Ward, “Learning Curve Models of Construction Productivity,” ASCE Journal of Construction Engineering and Management, Vol. 112, No. 2, June 1986, pp. 245-258. Back

- For a more extension discussion and description of this estimation procedure, see Hendrickson, C., D. Martinelli, and D. Rehak, “Hierarchical Rule-based Activity Duration Estimation,” ASCE Journal of Construction Engineering and Management, Vol 113, No. 2, 1987,pp. 288-301. Back

- Information on the MASTERFORMAT coding system can be obtained from: The Construction Specifications Institute, 601 Madison St., Alexandria VA 22314. Back

- Source: MASTERFORMAT: Master List of Section Titles and Numbers, 1983 Edition, The construction Speculations Institute, Alexandria, VA, 1983. Back