Vol. 1, No. 2 (December 2023)

Payton Needs a Prototype

Alexander Miller

All figures in Canadian dollars unless otherwise noted

On a hot July evening in the summer of 2022, Payton Mackey was walking back to her summer sublet in London, Ontario, Canada, frustrated and leafing through her prototype sketches. She had several product designs for her business, Fidgetry, and was anxious to get a physical product in her hands to show prospective customers. Her entrepreneurship program mentor had asked her why a prototype was so important. “I need to physically hold it; I need to know exactly what it will be before I can proceed,” Mackey had proclaimed. “How can I get customer feedback, build marketing materials, or do forecasting if I don’t have one?”

However, Mackey’s summer program was more than half over and each day she didn’t have a prototype stymied her progress even further. She found herself wondering how she would know what the right time and the right method was to get a physical prototype. Her mentor’s words stuck with her as she climbed the hill to her apartment. “Payton, you’ve done an amazing amount of research and seem to know every possible way to get a prototype, but your goal was to have this thing running by the time school starts again. You need to make a decision and put it in motion, there is no reason to come back next week still trying to decide.”

Mackey had all the information but needed to decide between six potential manufacturing partners ranging from small-scale and local to international, and between prototype specialists that all used different processes with different advantages. She also had to at least consider the idea of drastically changing her business plan and buying a pre-made product instead of commissioning the manufacturing herself.

Background

Payton Mackey

Originally from Kitchener-Waterloo area, Payton Mackey was a Dean’s Honor List student who had just completed her first year of business studies at Huron University College. Mackey enjoyed her first year and was looking to make the most out of her summer. She was accepted into the Morrisette Entrepreneurial Summer Internship and she was excited, as she felt this opportunity would give her plenty of business experience while still allowing her to visit home on the weekends.

Mackey’s goal was to design most of the business over the summer so that the operational demand would be minimal in the fall and winter when she was busy with her second-year studies. She also sensed that this business was about the learning experience and did not want to make a major personal investment in the business.

Morrissette Institute for Entrepreneurship

The Morrissette Institute for Entrepreneurship was born out of the Ivey Business School at Western University and has expanded to serve students of all disciplines and faculties on their business journeys.[1] The Institute provided access to coaching, learning resources, and funding, and acted as liaisons between young entrepreneurs and the broader Western and London community.

The Summer Internship Program[2] accepted a cohort of 15 students each summer, giving them access to start-up funds, a shared office space, and workshops to develop their business from concept to successful venture. Over the summer, students were expected to create a viable business model, conduct market research, formulate a sales and marketing strategy, build a financial model, develop sales skills, engage with potential customers, and construct a minimum viable product through prototyping to present to focus groups from their demographic.

Adult ADHD

Mackey decided to focus her business on adults with attention-deficit/hyperactivity disorder (ADHD). Mackey felt that, although society had made serious progress towards addressing and accepting ADHD in children, the market had not addressed the needs of adults with ADHD. Furthermore, Mackey wanted to start a business based on both profits and social good. For these reasons, she decided to focus on the needs of the adult ADHD demographic—one she was familiar with—and to address a pain point[3] of that market.

ADHD was a mental health disorder often characterized by one’s difficulty focusing, atypical hyperactivity, and problematic impulsive behaviour. While ADHD was commonly recognized and treated in childhood, if a person with ADHD was undiagnosed into adulthood, it could lead to unstable relationships, poor work and school performance, and low self-esteem[4] One of the symptoms Mackey often experienced was the impulse to fidget [5] with things. Fidgeting could cause adults with ADHD considerable anxiety in the workplace out of fear of causing a distraction and potential social misunderstandings.

Fidgetry

Mackey created Fidgetry to address the need for adults with ADHD to fidget discreetly in the workplace. Mackey knew her product would be for a niche market but was unsure of the actual size of the market. Knowing the size and dynamics in the market would also help her assess her competition. She learned of a main competitor that seemed to have a large market share that was selling devices for $25 each and had achieved a half million in sales over 10 years. It was early in the process, but Mackey envisioned an end customer price between $9 to $12 per unit, which would help her product remain competitive.

Mentorship Meetings

Huron University College offered students course credit for summer internships. Mackey combined the Morrissette Summer Internship opportunity with Huron’s interdisciplinary course credit. This enabled her to not only take advantage of the workshops through the Morrissette Institute but also to be supervised by her former professor, who had a background in entrepreneurship.

Mackey presented her plans for the business, including her designs. She expressed her desire to get a prototype as soon as possible as the mechanics of the products would be the main selling points. Her mentor expressed concerns that the designs and business plan may change as she got feedback from the target market. He suggested waiting until after some focus groups with adult women with ADHD and their particular needs. However, Mackey felt that not having a physical prototype would limit the customer feedback she would get from interviews and focus groups.

Design

The First Design

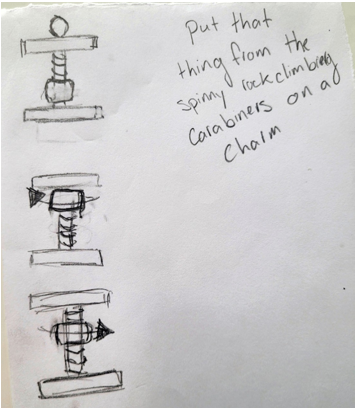

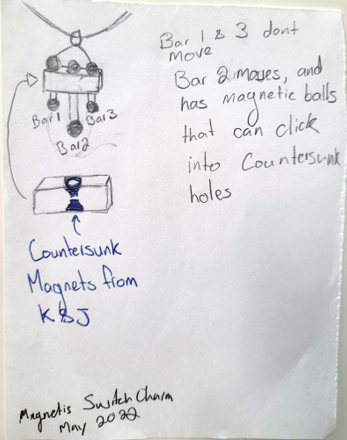

Mackey had a talent for designing moving, dynamic jewelry pieces. She had drawn up several designs upon being accepted into the summer internship program (see Exhibit 1 – Payton Mackey Sketches). Her goal was to create a collection of professional accessories, whose moving parts would allow for discreet fidgeting.

The Second Design

Mackey was struggling to figure out how to acquire a prototype and, in the meantime, conducted focus groups and interviews with the target market. After several discussions, she discovered that most of the individuals who had heard of fidget devices had tried them but tended to forget them. She also discovered that being discreet was more important than the type of fidgeting.

Based on this feedback, she expanded her potential product offering to include fidget devices attached to a keychain magnet. This way, the device would be portable, easy to remember, and could be used with one hand to avoid drawing attention. The commonality between products would be a magnet-based clasp on the keychain to allow easy removal of the fidget device from a set of keys or a purse.

Despite settling on a design, Mackey explored several methods to produce a prototype and needed to select a method promptly.

Manufacturing Types

Manufacturing Process

Mackey quickly learned a lot about manufacturing. She preferred that the final products all be made of metal to be durable enough for prolonged use. However, the prototype’s main purpose was proof of concept and to get market feedback. Mackey had identified several manufacturing processes that could be used to make the prototype and products.

CNC (Computer Numerical Control) Machine

A CNC machine[6] is a routing[7] device that carved or cut a programmed pattern into a material such as wood, metal, or plastic. The system used a three-direction axis to cut the right path into the material to carve out the desired components. Often several parts to the design were carved on one sheet of material and then assembled. Since some machines can cut patterns into many different materials, CNC manufacturing was prevalent in Ontario’s auto industry. The entire CNC industry was valued at $7.9 billion (US).[8] CNC manufacturing required an efficient design to minimize scrap material and make assembly simpler. Exhibit 2 – Typical CNC Machine demonstrates a typical CNC machine.

CNC Machines could cut directly from a .cad file[9] and a manufacturer would often offer in-house .cad or CAD file development. Mackey determined that CNC routing was, overall, more time-consuming than mold injections, described in the next section.

Mold Injection

Injection molds, which were usually made from steel, contained cavities in the shape of the object being manufactured. Melted plastic was injected into the mold, filling the cavities. The mold would be cooled, and the resulting object would be ejected by pins. This process was similar to a Jell-O mold which was filled, then cooled, to create the final product. The idea was to make a mold with the negative space for the object you desired; the melted substance filled those spaces when added to the mold. It was possible to complete this process with melted metal powder instead of plastic in a mold made of a metal with higher melting point.[10]

Molds lasted a long time and could be used for high volume production with a low unit cost. They also produced significantly less scrap than a CNC. This was because you would only use materials to fill in the parts of the mold you desired with only the path between components resulting in scrap. However, the cost for mold development was high, and any minor flaws in the mold or changes in design would be an expensive error. Additionally, to create the mold impression Mackey might have needed a CAD file to 3D-print, or to CNC manufacture a prototype first—all of which would increase the cost and time it would take her to produce the device.

Additive Manufacturing

Additive manufacturing was the process of creating an object by building it one layer at a time. This was most popularly known as 3D printing. It was the opposite of subtractive manufacturing, in which an object was created by cutting away at a solid block of material until the final product is complete. Though 3D printing was a much newer process, it had revolutionized manufacturing and become much more readily available due to its abundance of uses. See Exhibit 3 – Typical 3D Printer for an example of a 3D printer. The 3D printers themselves were expensive, but Mackey found that setting up a new design to produce was not as time-consuming and had a lower cost compared to injection molding. Overall, the scale for 3D printing better justified an initial investment. However, printing was a slow process and mass production was still better suited to the subtractive manufacturing processes. Additionally, while 3D prints of plastic are common, 3D prints of metal were still new and often prone to defects.

Computer-Aided Design (CAD)

CAD Design File

Mackey soon discovered she needed a CAD file to develop a prototype, no matter which manufacturing process she selected. These files consisted of a technical drawing, blueprint, schematic, or 3D rendering of an object.[11] She also needed special software to create, open, edit, and export these CAD files. Regardless of whether she wanted to print the prototypes herself, or use a local, North American, or international producer, she needed to have a CAD file made based on her sketches and designs. These files could be used to program 3D printers or CNC machines. She had identified three methods for creating this CAD file: She could learn to do it herself, contract out the task, or use a manufacturer’s in-house designer.

Learn CAD File Design

Mackey realized that, although she was not familiar with creating CAD files, she could gain free access to software to write her own CAD file. She could then use free online tutorials to learn how to create a design. She estimated a few weeks of tutorial and trial and error would result in a functional design for her product. However, she had reservations about the resulting quality of her product, given her limited experience, and wondered if multiple attempts would be needed when printing or producing the product from the file.

Third-Party Contracting

Mackey was familiar with the freelance service provider marketplace Fiverr[12]. She realized that she could easily find several people on the service with experience creating CAD files based on sketch designs. Based on a preliminary search, she figured it would cost between $60 and $100 per design to have the files created. Mackey felt these professional designs would be much less likely to have beginner errors but worried they would still not fit the specifications of the manufacturer she partnered with.

In-House Designers

Mackey had contacted several manufacturers who could produce the prototype and most of them offered an in-house designer to create the CAD file. Obviously, these files would work with their manufacturing process; however, they had minimum order quantities (MOQs) to ensure they’d recuperate the cost. Mackey had contacted a few manufactures who required $3000 to $5000 worth of orders for each design before they would consider making the CAD file.

Manufacturer Selection

Manufacturer

After Mackey had identified several options to make the physical prototypes, she figured she would likely need six to 10 prototypes for the first phase of the business.

Local Mold Injector

Southwestern Ontario was also home to several manufacturers who used mold injections to produce plastic or metal products. Mackey had contacted one such manufacturer, Precise Casting Inc., to learn more about mold injections.[13] MOQs for molding were much higher cost than CNC machines because a custom mold had to be created. The MOQs for her design would be $3000 per mold. She would have been able to use one mold per prototype design and would own the mold after creation. The mold would have contained all needed parts per prototype but still require some assembly and would cost $0.30 per product for materials and $1.20 per product for labour. This process seemed faster as there would be no delays in shipping and the cost to pick up a produced batch would be negligible, as the facility was within an hour drive of Mackey.

Local CNC Operator

Mackey knew that she could get similar advantages with shipping if she used a local CNC operator within an hour’s drive. The CNC operator required a base MOQ of $4000 but one CAD file could be used for all six to 10 prototypes. The cost per product was a bit more at $0.40 per unit and had similar labour costs. If she provided the CAD file, they would set the MOQ at $1500.

Local Additive Manufacturing

Mackey had found a Hamilton-based 3D printer, Canadian Additive Manufacturing Solutions (AMS), meaning she would be able to drive and pick up completed batches.[14] AMS offered in-house CAD design help or would use a file provided by Mackey. If an in-house designer helped create the CAD file, a MOQ of 200 units was required. If they produced from a CAD file Mackey provided, the MOQ was 50 units.

AMS would be able to produce a prototype quickly; however, each print run could take approximately four hours to produce one complete item. They could complete a working fidget device for $14 per item. Mackey was concerned that most 3D printing companies produced stationary objects and might struggle with designs intended for prolonged movement.

North American Prototype Specialist

Several facilities existed across North America who specialized in prototypes and working with small batch orders for start-up firms.[15] Mackey described these facilities as being for “problem projects” and were much more adaptable to unique design needs. These facilities required Mackey to use their in-house CAD development and had similar prices and MOQs to the local additive processes for in-house development. However, they would also include duties and tariffs that would impact cost, which she estimated at being an additional 2.5% in taxes and a $35 flat fee to ship.

The advantage of this alternative was the company’s willingness to work with unique needs; however, the shipping times were longer (two to three weeks). Furthermore, Mackey was concerned because she wanted magnets in the design, and magnets could require specialty equipment and a company that demonstrated the willingness to take on the challenge.

Offshore Production

Mackey had also contacted a number of international producers who could create prototypes to potentially implement into full scale production. These international producers had by far the lowest cost per unit at $5, however with the offshore companies the shipping costs were $200 and the times for the shipping were estimated at four to six weeks. Additionally, these producers required a two-month production time and the largest MOQ of $5000.

Community 3D Printer

Mackey did have access to 3D printers through a public library in Kitchener-Waterloo and a friend with a 3D printer also offered their assistance. The costs to use these were minimal. The prototypes would only take a few hours to print and be in hand immediately, however, the prototype would be plastic and not representative of the metal final product she wanted to produce. She was not open to the end product being made of plastic.

Buy

Mackey’s mentor had suggested finding a product that was already available for sale on the website Alibaba.com but that was not necessarily targeted at this niche group or purpose. This alternative would change the nature of her business from a producer to more of a broker, bringing an existing product to a new market. They looked together and found several suppliers of the clasps she was envisioning, as well as dozens of fidget products that could be attached to them, see Exhibit 4 – Fidgetry Products Pricing for examples and pricing.

Mackey know that she would want to order samples to vet suppliers if they went with this method. However, the challenge was that many of these distributors had MOQs or prohibitive prices for small quantities. They could also charge expensive shipping fees or have long delivery times, which could push back her business timelines.

Overall, this alternative would make her business more focused on creating a brand and proper distribution and marketing, rather than on product development. Her mentor challenged Mackey, suggesting that what she wanted already existed, explaining that “Goodyear didn’t invent the wheel, they simply learned how to market and distribute it better.” He warned her that inventing was costly and suggested that she focus on his true concern, which was how to reach such a niche market. However, Mackey really wanted the satisfaction of producing her own product with a design that better served the market.

Decision

Mackey’s mentor explained to her, “You are not marrying the decision. If you don’t like the end product or the process, after you try it, just switch. If you’re going to insist on a prototype to move forward, then get one.” Mackey responded. “In theory it is easy, but practically I’ll be busy with school again and don’t want to go through this whole vetting process again. I’d like to find my producer now and know what the plan is.”

As she reached her sublet after a long summer walk reflecting upon her prototype dilemma, Mackey realized that she was unlikely to find a perfect option and would need to compromise. She knew she would need to begin working with a provider immediately if she wanted to meet her summer add date deadline. However, selecting from among her narrowed list of six manufacturers would require her to identify her priorities. Mackey also knew that she had to explore the option of buying a premade product, even though she had never imagined she would consider this approach when she submitted her application to Morrissette. Now, resigned to making a compromise in her prototype design, Mackey wondered where she should start.

Exhibits

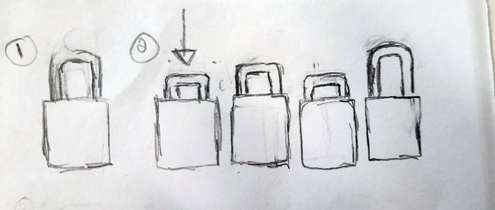

Exhibit 1 – Payton Mackey Sketches

Exhibit 2 – Typical CNC Machine

Exhibit 3 – Typical 3D Printer

![An illustration of a 3D printer demonstrating how it functions [see image description].](https://ecampusontario.pressbooks.pub/app/uploads/sites/3000/2023/10/exhibit_1_2_4_3-1024x1024.png)

Exhibit 4 – Fidgetry Products Pricing

| Possible Products | Customization | MOQ | Order Quantity | Price Per Unit | Shipping Cost | Total Price Per Unit | Total Cost |

|---|---|---|---|---|---|---|---|

| Product #1 | Yes | 20/1000 | 100 | $0.08 | $41.84 | $0.4966 | $49.66 |

| Product #2 | Yes | 200 | 200 | $0.72 | $104.54 | $1.2393 | $247.86 |

| Product #3 | Yes | 1/100 | 100 | $0.65 | N/A | $0.6515 | $65.15 |

| Product #4 | No | 100 | 200 | $0.85 | $114.41 | $1.41895 | $283.79 |

| Product #5 | Yes | 10 | 200 | $0.39 | N/A | $0.3909 | $78.18 |

| Product #6 | No | 200 | 200 | $1.70 | $39.96 | $1.8998 | $379.96 |

| Product #7 | Yes | 60/300 | 120 | $2.74 | $136.31 | $3.875917 | $465.11 |

| Product #8 | Unsure | 20 | 100 | $0.34 | $57.76 | $0.164 | $9.64 |

| Product #9 | Yes | 12/50 | 100 | $2.30 | N/A | $2.3 | $230.00 |

Source: Based on market research completed by Payton Mackey.

Image Descriptions

Exhibit 1– Payton Mackey Sketches

Photo A includes three sketches of an I-shaped tool with a spiral down the middle showing different positions of a ring on the spiral. A handwritten note says “Put that thing from the spinny rockclimbing carabiners on a charm.”

Photo B includes the sketch of a rectangular cube charm with three vertical bars numbered 1, 2, and 3, with balls on the top and bottom, The charm is on a large ring. An arrow pointing to the rectangular charm originates from another rectangular cube with a shaded hole in center and the handwritten label “Countersunk Magnets from K&J.” A handwritten note on the right of sketch says “Bar 1 & 3 don’t move, Bar 2 moves, and has magnetic balls that can click into countersunk holes.” A handwritten note on the bottom of the sketch says “Magnetis Switch Charm, May 2022.”

Photo C includes 5 sketches shaped like padlocks in a row; the first sketch is labelled 1, the second sketch is labelled 2 and has an arrow pointing down to it from above.

[back]

Exhibit 3–Typical 3D Printer

A schematic image which consists of a box with a large circle on the top right ( labelled A) and with a platform at the bottom (labelled E) between two posts. Arrows above and below the platform illustrate that the platform moves up and down the posts. A silhouette of a female bust sculpture on the platform (labelled C) is being printed. An arced line from the large circle passes through two cogs in a small box labelled B on the top of the main box. Lines (labelled D) run from the chin and back of the head down to the bottom of the bust. An arrow on either side of the small box illustrates that it moves back and forth to print the top of the head of the bust on the platform.

[back]

References

Buchan, C. (2021, May 6). $5.5-million gift expands entrepreneurship opportunities at Western. Western news. https://news.westernu.ca/2021/05/5-5-million-morrissette-gift-expands-entrepreneurship/

Iqbal, K. (2020, February 6). Learn about CAD file formats and APIs that can open and create CAD files. https://docs.fileformat.com/cad/#:~:text=CAD%20file%20is%20a%20digi- tal, used%20CAD%20drawing%20file%20formats

Mayo Clinic. (2019, June 22). Adult attention-deficit/hyperactivity disorder (ADHD). https://www.mayoclinic.org/diseases-conditions/adult-adhd/symptoms-causes/syc-20350878

Mordor Intelligence. (n.d.). Computer numerical controls (CNC) market size, share: 2022 – 27: Forecast, growth. Retrieved September 14, 2022, from https://mordorintelligence.com/industry-reports/computer-numerical-controls-market

Rogers, T. (n.d.). Everything you need to know about injection molding. Retrieved September 14, 2022, from https://www.creativemechanisms.com/blog/everything-you-need-to-know-about-injection-molding

ShopBot Tools. (n.d.). ShopBot blog. Retrieved September 14, 2022, from https://www.shopbottools.com/community/blog/what-is-a-cnc-router- and-how-does-it-work

Download a PDF copy of this case [PDF].

Read the Instructor’s Manual Abstract for this case.

How to cite this case: Miller, A. (2023). Payton needs a prototype. Open Access Teaching Case Journal, 1(2). https://doi.org/10.58067/5ma2-sk49

The Open Access Teaching Case Journal is a peer-reviewed, free to use, free to publish, open educational resource (OER) published with the support of the Conestoga College School of Business and the Case Research Development Program and is aligned with the school’s UN PRME objectives. Visit the OATCJ website [new tab] to learn more about how to submit a case or become a reviewer.

- Buchan, 2021. ↵

- Buchan, 2021. ↵

- Pain point was a term used to describe a typical struggle or grievance of a target market in their daily lives that they would in theory pay for a solution to. ↵

- Mayo Clinic, 2019. ↵

- Fidgeting was a term used to describe making small movements with your body, usually your hands and feet. It was associated with not paying attention and often reflected discomfort and restlessness. ↵

- ShopBot Tools, 2020. ↵

- Routing is the term for the shaping of a material using cutting and trimming, often at a high speed. ↵

- Mordor Intelligence, n.d. ↵

- cad is the extension for a 3D graphics file, created using computer-aided design software. ↵

- Rogers, 2015. ↵

- Iqbal, 2020. ↵

- See the Fiverr website for more information. ↵

- See the Precise Castings Inc. website. ↵

- See the Canadian Additive Manufacturing Solutions website. ↵

- For example, see the Au Enterprises website. ↵