Vol. 1, No. 1 (March 2023)

Mother Myrick’s Confectionery

Paul W. Thurston, Jr.; Erik R. Eddy; and Daniel C. Robeson

All figures are in U.S. dollars unless otherwise noted.

Mother Myrick’s Confectionery, located in Manchester, Vermont, had been continuously operated by Ron “the fudge man” Mancini and his wife Jacki for 35 years.[1][2] The couple opened the fudge shop and bakery in the centre of town in May of 1977, added an ice cream parlour in June of 1978, and began their mail-order business in November of 1978.[3] Revenues for retail and mail order grew to more than $1 million in 2004, but the company was not profitable. Ron and Jacki considered liquidating the business, but chose instead to close their downtown shop, shed the ice cream operation, and relocate the retail store to the edge of town. In the process, the company took on $205,000 in notes payable. In 2012, company revenues topped $800K (see Exhibit 1 – Income Statement and Exhibit 2 – Balance Sheet: Assets and Liabilities). The business provided a salary of about $60,000 for Jacki and positive income in each of the last four years. Ron stopped taking a salary in 2007 when he began collecting his Social Security benefit. A balloon payment[4] on a Berkshire Bank note was due in a couple of weeks, and the couple had to decide whether to pay it off, refinance it, or consolidate it into a larger loan and use the proceeds to improve operations.

Ron and Jacki wanted to retire and needed a plan for the transition. They had no children together, and Ron’s children from his previous marriage were not interested in the business. The couple thought of passing the business to their employees but were unsure if any of them were ready to take the lead or if they had access to that kind of capital. Selling the business outright was an option, but taking on new debt now would make the company less attractive. Selling the business outright was an option, but taking on new debt now would make the company less attractive. They could also close the shop and sell off the assets. In Ron’s mind, the best scenario was to bring on new partners and teach them the business, possibly a younger couple who was tired of the city life and wanted something different. He imagined people like he and Jacki when they started the business. The new owners could carefully nurture the business and bring it to the next phase. The company had sufficient cash to pay the loan, but that could leave them short in the fall when they were busy making product for the holiday season. Interest rates were still low, and Ron thought they could borrow the money needed to pay off their existing debts and get additional capital. They could use the capital to consolidate debt, expand, or improve operations. Ron developed a one-page business plan in January 2013 (see Exhibit 3 – One-Page Business Plan) and provided it to several area banks.

Company Growth, Retraction, and Relocation

Ron learned his craft from a Massachusetts candy maker in the early 1970s. He continued his confectionery education with an apprenticeship at Boehm’s Candies in Issaquah, Washington, and a series of professional courses offered through Retail Confectioners International and the Barry Callebaut Institute.[5][6][7] The company started with a line of assorted caramels, and a chocolate and nut–covered toffee named “Buttercrunch,” which turned out to be the company’s bestselling product. Jacki brought her expertise in food and customer service to the fledgling business. Mother Myrick’s grew with the popularity of the company’s fudge, Buttercrunch, and caramels. When Ron and Jacki started the company, the bank kept them afloat on a series of 90-day notes. They purchased the raw ingredients, made a batch of fudge, loaded it in the van, and hit the road. After selling all the fudge, they would come back, pay off the loan and repeat the process. In the early days they would do 50 to 60 food shows each year. The road trips gradually decreased as the business grew. They opened the fudge shop and bakery in the centre of Manchester in May of 1977, added an ice cream parlour in June of 1978, and began their mail-order business in November of 1978.[8]

The ice cream parlour featured an old-fashioned marble-topped soda fountain, umbrella shaded tables, and the smiling faces of Burr and Burton Academy students working behind the counter.[9] Off to the left, patrons would find Manchester’s bearded fudge man, cooking his concoctions in a big copper kettle, and offering fresh samples of fudge from the paddle (see Exhibit 4 – Jacki and Ron Mancini Early Years for photos). In 1983, they created a separate place for the chocolate shop, where display cases highlighted the changing seasons with chocolate treats; and a café/bakery featuring European tortes, pastries, cookies, pies, and Mother Myrick’s bakery specialty, the Lemon Lulu cake (see Exhibit 5 – Mother Myrick’s Candies, Chocolates, and Fudge and Exhibit 6 – Mother Myrick’s Bakery Favourites for a sampling of their products). Throughout the expansion, Ron and Jacki stayed true to their goals of producing high–quality products, delighting their customers, and promoting the growth and wellbeing of their employees and the Manchester community.

In 2005, Ron and Jacki bid farewell to their downtown location and ice cream parlour and moved their retail operations to the southwestern part of Manchester Center. They also moved the baking kitchen so that it would be co-located with the offsite production and shipping centre, in an industrial park located about a mile (1.6 km) outside of town. The company had been leasing 4000 square feet in a single building for candy production, packaging, and shipping since 2001. The move allowed Ron and Jacki to concentrate on the growing demands of the mail–order and retail sales of its chocolates and cakes and reduce their operating costs. According to Ron, the decrease in operating costs with the closure of the downtown shop was greater than their loss in revenues.

By 2004, we were paying over $50,000 each year for the downtown location. We were operating the ice cream parlour and retail store out of the first floor of the downtown store and baking on the second floor. We paid another $25,000 for additional space in the industrial park where we did the candy production, packaging, and shipping. We were losing money at this point and the owner of the downtown location wanted to raise the rent. We were also terribly inefficient. We baked Lemon Lulus on the second floor, walked them down the stairs – six to a sheet pan – put them in the car, drove to the industrial park location, and then got them ready to pack and ship. We did that three or four time each day. We negotiated a six-month checkout. We shut the ice cream parlour down on New Year’s Eve 2004 and shut down the rest of the operation on Easter. We opened in the new retail space on Memorial Day weekend in 2005.

The new retail space was located on 4367 Main Street (see Exhibit 7 – Mother Myrick’s Proprietors Jacki and Ron Mancini with Pies at the Retail Location). The building contained 1,000 square feet (93 m2) of retail area at the front of the building and 500 square feet (46.5 m2) of office and store space in the back. Rent for the retail store was $1,650 each month. The company signed a five-year lease with a five-year renewal option. The new location would not provide the walk-up traffic they had been accustomed to, but had ample parking for retail sales and came at a fraction of the cost. Ron believed moving to the new retail was the best decision in a situation where no alternative were optimal. He explained:

We opened the doors of the new retail space and you know what the people said? “We want Buttercrunch. We want Lemon Lulus. We want Birthday cakes.” There was plenty of parking and easy access. It doesn’t mean it wouldn’t be nice to be in town. But the problem back in ‘05 was that we couldn’t find a space that was small enough. We didn’t need a 3,000 square foot store. Ideally, a 1,500 square foot space would work, but nobody would give us that. That was a critical point. Jacki and I looked at each other and said, “why don’t we just let the bank take it?” In the end, we chose to stay in the business because we realized that we were important. Too many people would lose too much and would be out of work. We also wondered who would hire us. We needed to be in control. We got a bank loan for $175,000 and borrowed $30,000 from a couple of friends. The loans from our friends appear on our financial statements and we pay interest of 6%.

Baking and candy making were located in separate parts of the production, packaging, and shipping facility at the industrial park. Approximately 700 square feet (65 m2) was dedicated to baking and 1600 square feet (149 m2) had dual use for candy making and packaging/shipping. About 100 square feet (9.3 m2) was set aside as shared office space. Rent for the production facility in the industrial park was $1,445 per month in 2012. Everything they had was standard for the industry. The equipment and facilities were sufficient to meet the current demands as long as they employed flexible scheduling to extend the production day (see Exhibit 8 – Candy Kitchen and Shipping Area for photos of the production space).

The Confectionary Industry

The 2008 recession affected the United States confectionery industry for about a year. Tonnage of sales decreased from 2008 to 2009 and retailers increased prices to maintain profits. Confectioneries turned out to be an affordable alternative that people used to treat themselves, and others. Sales reached $32 billion in 2012 with a projected compound annual growth rate (CAGR) of 3% through 2017.[10] The confectionery industry consisted of more than 1600 companies employing 50,000 workers. Most companies were small, with 80% having fewer than 20 employees.[11] Increased prices drove sales growth for chocolate rather than increased product volume. According to Mintel market research:

The chocolate confectionery industry has maintained slow growth over the past five years as the economy tries to recover from recession. This growth was driven in large part by continued demand for affordable indulgence; an increased interest in high-quality artisanal foods, including chocolate; and price increases due to rising ingredient costs.[12]

The chocolate industry raised prices and decreased portion size to offset higher costs of cocoa, sugar, and other ingredients. The product mix within the sector also changed with specialty, gourmet, and artisanal chocolates growing at rates that were close to 10%. The World Cocoa Federation’s Economic Profile of the U.S. Chocolate Industry reported that 400 companies manufactured more than 90% of the chocolate in the U.S.[13] Larger companies derived profits from economies of scale in the supply chain and manufacturing processes, while smaller companies tried to differentiate themselves through specialty products and services.[14] Expected growth for seasonal and boxed chocolates was 13% each year through 2015. Halloween was the most important holiday for the mass-produced varieties, while Christmas, Easter, and Valentine’s Day were most important for specialty and gourmet chocolates.

Competitors positioned themselves at various points in the market to satisfy these customer needs. Large, heavily branded products manufactured by Hershey’s, M&M Mars, and Nestle dominated the lower end of this market with a retail price of about $5 per pound (454 g). In the middle range were premium chocolates including Ghirardelli, Godiva, and Lindt, retailing at approximately $15 per pound. At the high end of the price range were the local boutique competitors, like Mother Myrick’s, which produced specialty confectioneries retailing at $30 per pound and up. Boutique competitors competed with the larger companies’ products sold in local establishments and with each other when co-located in communities. There were no local boutique competitors in the Manchester, Vermont, area. However, Mother Myrick’s was now competing with boutiques due to the increased use of the internet.

Chocolates and other confectioneries were readily available in most retail outlets, including convenience stores, groceries, supermarkets, and department stores. The same was becoming true for the premium brands. Boutique manufacturers typically sold their product in their own retail outlets. Boutique operations also made their products available through mail-order catalogues and through the internet. Catalogue and internet sales were especially important to the boutique manufacturers because they reduced dependence on the health of the local economy.

Employees and Organizational Responsibilities

Jacki and Ron employed 10 staff year-round and as many as 16 employees during peak operations in November and December. Jacki ran the retail side of the business and had two regular employees in the retail store. Ron managed the mail-order division, as well as the production activities. The company tracked revenues and costs for retail and mail order separately (see Exhibit 1 – Income Statement).

The key employees in the production facility included Ben, Hans, and Emily in the bakery; Debby and Kristin for candy production and packaging; Sarah for order control; and Kathy and Silesia for mail order and bookkeeping. Ben performed all of the scheduling for the bakery and Debby performed that function for the candy kitchen. Debby also had the responsibility for packaging and shipping. Hans and Emily worked with Ben in the bakery and could help Debby in the candy kitchen when needed. Kristin was Debby’s year-round assistant. Debby could have four additional staff for packaging and shipping during the busiest times in late November and December. Sarah, the controller for the company, came in during the evenings and staged all of the orders. She would come into the shop for two hours every night, seven days a week, during the peak shipping season. Sarah checked every order against the original to make sure there were no errors in the packing slip. Kathy started out seasonally in 2002, and just came in for the mail-order season during November and December. She began working year-round in 2007. Ron described Kathy as critical for the back end of the operations:

Kathy does all of our bookkeeping. She is the key person for our customers who order over the phone. They love her and all want to talk to her before they will talk to me. Everything that goes through Debby goes to either Kathy or me, and most of the time it’s Kathy. We have a delicious schedule worked out between the two of us. She doesn’t want to work full-time, preferring to be in her garden in the summer, and that happens to be our slowest time of the year. She likes to work a couple of days each week in the summer. As the mail orders begin to pick up in the fall, she’ll go to three and then four days a week. For December through the early part of January, she works five days each week and then gradually tapers off as she catches up with all of the paperwork in the early spring.

Silesia assisted Kathy and worked as needed on a per diem basis. She entered all of Jacki’s retail sales records into an Excel spreadsheet by date and processed all of the bakery mail orders. She also entered contact information for all the people Ron and Jacki met at promotional events. Ron stated:

We collect contact information from the people we meet at shows when they register for our one-pound Buttercrunch giveaway. Silesia codes all of this information in the database with the date of the sale or the event. This way we can do our direct marketing campaigns to specific audiences and measure the effectiveness. For our largest samples, we can measure conversion rates for the number of contacts that turn into customers.

Ron provided opportunities for his employees to cross train in different functions until they found the job for which they were very well suited. For example, Ron described Emily’s changing roles with the organization.

Emily began working part-time with Debby on the candy side of the business in 2010, first on the Buttercrunch line and then with packaging and shipping until 2012. In 2012, we had a need in the baking side of the house and Emily gladly moved over. She has a passion for cake decorating and would eventually like to own her own bakeshop. She has been doing amazing work.

Ben provided another example of how employees could find their niche. Ben started with the organization in 2001 and worked his way up to head of the bakery department with total responsibility for scheduling and ordering. According to Ron:

Ben happens to be our least skilled baker, but organizationally he’s brilliant. You can’t put a pastry bag in his hand, but he can make 300 Lemon Lulus in a day without breaking a sweat. He does all of the straight-up baking and then Emily and Hans do the finish work. All three of them can do the entire line, except Ben can’t do any finish work. No piping, no spatula. He has big thumbs, but he’s amazing with numbers.

Ron explained that the current situation was unusual. There had been only three master bakers in the 30-year history of the bakeshop. In each case, one person served as master baker, pastry chef, and head of the baking production. They were responsible for product development, scheduling, procurement, baking, and finish work. After their last master baker left in 2011, Ron decided to divide the responsibilities among the members of the baking team.

We gave Ben responsibility for scheduling and procurement, which has been a good growth area for him because, even though he had the skills, he never had the chance to apply them. Ben knows what our seasonal requirements are through Jacki, and through our inventory management system, which tracks sales. His first year in the job, he thought he could keep it all in his head. That worked well until things got busy his first November and December. We let him go until it looked like he was close to a nervous breakdown, and then we threw him a life preserver. I pulled him out of the kitchen and the two of us scoped out how we thought it should be. We took a big piece of parchment paper and drew boxes for calendar days and he listed off all the key tasks. For example, morning baking happens every day. Sometimes it’s for an hour and other times it will be two to three hours. It’s going to be heavier on Friday and Saturday than it will be on Tuesday or Wednesday. He would then indicate times for packaging and shipping and identify when he needed his staff.

Hans and Emily were in charge of the creative side of the bakery operations including product development. Hans began working part-time for Mother Myrick’s in 2005. He was a Swiss national, trained as a pastry chef when he was in high school, who then worked for the Marriott-Hilton chains opening up hotels and restaurants for 30 years. Ron explained that everyone was clear on their duties and were willing to help in areas outside their areas of expertise.

My staff is great. They love to work, and they take responsibility for the product. When we make the Buttercrunch, everyone steps into the process. Emily, Ben, and Hans from the bakery join Debby and Kristin. They manage other duties around the Buttercrunch production. The staff has discretion. I don’t micromanage Ben’s or Debby’s labour or production schedules, but I do stay aware and informed. I’ll make suggestions where I think it’s needed. I’ll also weigh in on out of the box decisions where they feel uncomfortable making a decision.

Seasonal Production

Ron tried to make maximum use of their production space. They accomplished this by focusing production on specific products during certain times of the year. Demands on the candy kitchen dropped during the summer, even though Manchester was a tourism town. The company didn’t ship a lot of chocolate in the summer because of its heat sensitivity. Christmas was by far their biggest season with 65% of the candy sales. Easter was next, with Valentine’s Day a distant third. Bakery operations were more even throughout the year because of daily demand of everyday items and cakes for special occasions. Because of this, they dedicated summertime to Buttercrunch production. Ron explained:

We use this time to get ahead on Buttercrunch, which we ship toward the end of the year. Demand for Buttercrunch is highest during November and December, and we could never keep up. The product has an incredibly generous shelf life frozen – more than a year. We start around mid-May and will produce Buttercrunch until mid-August. We package about 60% of it into the gift boxes right away. We palletize the product and ship it to our freezer storage facility in New York State. In November, we start calling the pallets back to fill the orders. We keep the remaining Buttercrunch here loose, in 30 to 40-pound cases in our 10–by 20–foot [18.5 m2] walk-in freezer located outside near the loading dock. The space is totally inadequate for our needs. We end up storing some of the product on our loading dock for a few weeks in late November and December. It’s certainly cold enough outside.

Debby did all of the scheduling for the Buttercrunch production. Ron was part of the Buttercrunch cooking team. Ben and Hans helped with cooking and chocolate dipping as Debby needed them; otherwise, they worked the bakeshop. By the middle of August, they were finished with Buttercrunch production and began working on more time sensitive products like truffles, caramels, and brittles. According to Ron:

We produce those products through November. If we have done it right, we stop candy production just before Thanksgiving and convert the candy kitchen into a staging area for packaging. We use every flat surface, the counters, tabletops, and even the water-jacketed table. At that point in time, we shift our production emphasis to baked goods for mail order and the retail store. For the retail store, it’s our decorated cakes for formal events like birthdays and anniversaries and our Lemon Lulu cakes. The Lemon Lulu is our big deal bakery item for mail order, as well as our bestselling item in the retail store.

The bakery went into aggressive baking mode after Thanksgiving. The reasoning behind the delayed start was primarily due to storage space. A case of Buttercrunch with a retail price of $185 took up less space than that required for a single small Lemon Lulu, which sold for under $30. Storage did not degrade either line of products. A Lemon Lulu stayed fresh for eight to ten days on the counter, and for six months frozen. Ron explained that they were able to extend daily bakery operations by staggering the arrival and departure times of employees.

During those two months, going to staggered shifts extends the oven time for two to three hours each day. We can do this and avoid a second shift. I think working people in the middle of the night is personally degrading and demoralizing. It’s better to have people arriving at 6:00, 9:00 and 11:00 in the morning. This allows us to get a twelve-hour run out of the ovens rather than six or seven hours.

The company also dealt with limitations of the physical space by making dual use for the candy kitchen as an area for extensive pack and ship operations. Ron described his rationale:

You can’t build a church for Easter Sunday. On that one day, you’ll have people standing in the hallway, but every other weekend there’s plenty of room. We do the same thing here. That’s why the candy production stops so that we can meet the demands for packaging. What would we do with another 5,000 square feet for 11 months out of the year?

In December, they brought computers and telephones out of storage and set up extra stations for handling phone and internet sales. Debby’s workstation for candy scheduling became Silesia’s workstation for data entry and phone sales. Their focus was almost entirely on order processing and fulfillment. Ron explained:

We worry about paying bills during this busy time. We are so busy with mail order that three months of sales receipts just pile up. The only bookkeeping that Kathy does in November and December is putting bills in, giving me a cash-in current report, writing checks, and getting them mailed. On January 1, Kathy has the daunting task of putting three months of sales into the database. Some of these are complicated. We take orders, but credit cards aren’t charged until the orders are shipped. Kathy has to match up the order, which can be advanced dated, to credit card payments, which can’t be advanced dated. In 2013, I kept Silesia on for the month of January to help Kathy. It might take a couple months for her to catch up.

Order Processing, Direct Marketing, and Information Management

Mother Myrick’s recorded orders in M.O.M., the multichannel order manager inventory management system.[15] They entered contact information, including the name, company name (when applicable), address, phone number, and email for both the “bill to” and “ship to” customers. They assigned each customer a number that facilitated tracking and direct marketing; and listed all items in the entire catalogue with quantity, price, and total. They also used M.O.M. to record gift message, requested arrival, assigned shipping date, shipping method, optional discounts, subtotals for merchandise and shipping, order total, payment method, date entered, and entry person for each order. Sometimes they processed orders right away. Other times they delayed processing so that the product arrived in the future. According to Ron:

M.O.M. is critical to keep us on track. We can retain orders for six weeks or more. We might get an order at the end of October for a December delivery. Sarah comes in the evening, looks at the order form, looks at the packing slip, and makes sure everything matches. We keep the paper copy of the order form and file them by the date the order was placed. At the end of the year, we put all of the order forms into a storage box. Three or four years later, we send them to the shredder.

The system also provided a field to record comments that helped the organization provide tailored service to each of their customers. Ron explained that Kathy was much better at recording useful comments.

Kathy writes comments on everything. I’m not that disciplined, but I appreciate it when I need it. Here’s an example that’s Kathy’s doing: “birthday is December 2, 1930, name is Shelomith but wants to be called Lilly, husband passed in 2011.” Everything in the system is searchable. Lily’s been ordering from us since 2001. I can look up all of the people that she has sent our products to and what she sent them.

Ron also managed his customer list with information from M.O.M. He could run a list of buyers and the number of years they purchased product. Ron found that 50% of first-year buyers return the next year and 75% of second year buyers return for a third year. Retention rate for customers who have purchased orders four years in a row was greater than 90%. Ron explained how he used this information.

I can go in and look at my 2009 buyers who didn’t reorder. I can look at how many orders they produced and what was the gross revenue for them. Some buyers placed 14 orders in their lifetime with us and stopped. Others placed one order and stopped. I can’t do much about that one, but what happened to the person who placed orders for 14 years? Kathy and I were both surprised this year [2013] when a customer who had been in our system since 2000 ordered for the first time. They gave us their name and address in our store to get on our mailing list.

Although Ron and Kathy had the ability to focus on a particular customer, they did not normally use that information for direct marketing. According to Ron:

We seldom segment our email list. Everybody gets it whether they like it or not. We subcontract the email function. They can tell me the numbers for people that opt out and addresses that are no longer valid. The system no longer sends messages to people after the address is rejected five times.

Beyond email, the company sent catalogues and post cards to people on their mailing list, and would participate in shows where they collected names through their Buttercrunch giveaway. They coded all of this information in M.O.M. This allowed them to track the relative success of their marketing efforts. The company had been increasing advertising expenditures the last four years: $16,000 in 2009, $22,000 in 2010, $26,000 in 2011 and $32,000 in 2012. Ron was interested in investigating the effects of different marketing efforts and planned to experiment with different techniques on random segments of the customer base in the coming year.

Ron could also pull sales information by period to show the company’s activity and could manage inventory from the time they put it into the system. He preferred analyzing the data using a spreadsheet, rather than rely on the reports generated from M.O.M.

I don’t find the spreadsheets generated by M.O.M. helpful. I can dump the data into Excel and figure how many pieces we have to make. We break the pieces into weight and break the weight into the batch size. We then know how much we have to make, and we just go make it. We base how much to make each year based on history. We sold 100 boxes of these last year, so let’s produce 110 this year; or last year we produced 110 and only sold 90. So, let’s just do 95. My Excel knowledge is not sophisticated enough to produce graphs of products made and sold over a period of years.

Shipping

The cost of shipping in a safe and effective manner was a major concern Mother Myrick’s, as it is for the entire specialty food industry. There were a couple of reasons for this. The first was the price of the product compared to the price of shipping. According to Ron:

People don’t mind paying $10 shipping for a $500 cashmere sweater. It’s different when it costs $10 to ship a $30 cake. There is a limit to how much we can pass on to our customer.

The second reason was the time it took for shipping compared to the cost of shipping. At one time Mother Myrick’s used United Parcel Service (UPS) exclusively for all of their shipping needs. They now used the United States Postal Service (USPS) for about 80% of their business. Ron explained:

I can ship a Lemon Lulu to the west coast via UPS ground for about $11. For an extra $1 I can get it there with the Post Office priority mail in two days. We charge a flat fee of $10 to ground ship a Lemon Lulu. We’ll lose a little shipping to California and gain a little when shipping in New England. It all averages out and avoids presenting a complicated shipping schedule to the consumer. In 2011, we began comparing the outcomes for shipping with the Post Office compared to UPS, and we found that the Post Office was as good, if not better.

The company invested in shipping software that allowed the operator to determine which company to use and then print the appropriate label. The software also allowed the operator to input a universal shipping code and get a recommendation on the most cost-effective method for shipping (e.g., UPS or USPS). The shipper could then choose the best mode of transportation and print the appropriate label. Ron explained why they had not fully implemented this feature:

We don’t have the shipping infrastructure to use this feature. On any given day, we might have 500 packages that we need to pick, pack, and have ready to ship for the carrier to pick up at 3:00. There’s just not time to sort the packages by carrier.

The organization also invested in custom packaging for their Lemon Lulu cakes. They packaged the cakes into corrugated cardboard shipping cases right after baking, and then stored them in the freezer. To ship, they pulled the cake in its box out of the freezer, inserted the packing information, placed a shipping label on it, scanned it, and put it out to the loading dock.

Retail Operations

The retail store was open seven days a week – Monday through Friday from 10:00 a.m. to 5:30 p.m., Saturday from 9:00 a.m. to 6:00 p.m. and Sunday from 10:00 a.m. to 5:30 p.m. The store operated every day of the year, except Thanksgiving, Christmas, Easter, and a few days at the end of April to conduct spring-cleaning and inventory. Their company’s fiscal year ended on April 30.

The storefront featured custom-made display cases from the original downtown location. Buttercrunch took centre stage, surrounded by assorted caramels, truffles, brittles, and fudge. Every item in the display cases was produced in the company’s bakery or candy kitchen. Some items along the walls, like chocolate in foil, jellybeans, and hard candies, were purchased through a supplier in bulk and then packaged on–site. Jacki received their own products from the candy kitchen in prepackaged configurations sold through the mail-order catalogue, as well as in bulk. Jacki described the process:

They send over much of the candy product in bulk. We package the chocolates for seasonal promotions and use standard and small specialty boxes. We also try for unique presentation. We have some little presentation boxes in two heights. One has four trays and the other has two. It is a nice alternative to the traditional heart box.[16]

They also displayed baked Lemon Lulus, coffee cakes, tarts, pies, and cookies in the custom-made cases. An item that was featured in the retail store, but not available through mail order or on the internet, were the Lemon Lu-Lettes, a miniature version of their bestselling bakery item. Jacki explained the history behind this lemon cake.

The recipe belonged to Ron’s Aunt Lulu. It’s a pound cake that’s lemony, not too sweet, and covered with a fresh lemon glaze. Lulu came to visit from Old Lyme, Connecticut, and brought her own birthday cake. At the time, we were baking cookies and things at home, but hadn’t yet opened the bakeshop. We followed her recipe and brought the finished product into the store. Customers loved them. That was over 30 years ago. Today they are our most popular bakery item. We started making the Lu-Lettes at a customer’s request. She had been buying the large Lulus for a fundraiser dinner, serving everyone a slice. At some point, there were just too many people, and she asked if we could make them in an individual size. We did the research, tested several pans, and ended up with the Lu-Lette. The day after the fundraising event, we had people coming in and asking, “Where are those little Lulu cakes?” We’ve been selling them in the store ever since. It’s fun!

Jacki sold fresh and frozen pies out of the retail store that she baked in an oven in the back. The product mix changed to coincide with holidays and seasons, as did the store decorations. Jacki described their current emphasis for Valentine’s Day.

Right now, we are featuring heart cakes produced by our bakery. Hans and Emily are the creative force behind the designs. We are packaging our Lu-Lettes with little chocolate hearts to make them a Valentine’s gift. We normally sell the little cakes in six-packs or larger quantities. We always have Lemon Lulu and coffee cakes, cookies, and brownies on hand in the store.

Giving Back to the Community

Ron and Jacki considered themselves active members of the community and did their part to support the town and its events. Mother Myrick’s began its annual Easter Egg Decorating Contest in 1981. Entire families participated in hopes of winning “Annabelle,” a 30-inch (76 cm) tall chocolate bunny. In 1989, Jacki started a summer reading program for children. The program rewarded children with special treats and hidden treasures from the bakery for reading and making projects. In 1991, to help key charitable causes such as Mothers Against Drunk Drivers (MADD) and The Susan G. Komen Foundation, Jacki began a Decorate a Cake for Mom event for Mother’s Day.

All proceeds go to charity. The kids have a ball and Mom gets a personally decorated cake. We’ll have the entire store filled with children from four to eight years old. They each get a vanilla cake with butter cream frosting and all the supplies to decorate it.

Mother Myrick’s also supported the local community through their participation in the Taste of Vermont event and by being a part of Vermont Public Radio Listener’s Picnic. The company was a long-term underwriter for WAMC Public Radio, a family of radio stations serving southern Vermont, western Massachusetts, and the northeastern part of New York.

Thoughts About Continued Growth and Succession Planning

Jacki and Ron had not discussed succession with the staff but acknowledged that there may be some level of concern. Ron jokingly quoted Kathy, while in her presence:

Kathy says to me, “Ron, you are the only one who takes care of payroll. What happens if you and Jacki take a vacation in Vietnam and drown in Halong Bay? What are we going to do? How are we going to ensure that we continue operations and get paid?”

Kathy laughingly denied the quote, stating that Ron was definitely paraphrasing. She did seem to agree with the sentiment, which nudged Ron to reply:

We just haven’t had the inertia to make that happen. Kathy goads me a little bit. It’s not because Kathy wants control or that I don’t want to give up control. There are some things that I really like to do, and there are other things that I feel are proprietary in nature. Even relative to our staff, where we have a good and open relationship. That said, at some point things won’t be able to continue the way they have in the past. We have a good thing going and no one wants to see it end.

Ron thought they had four basic options. They could have sold the business outright, brought in a partner, facilitated an employee takeover, or liquidated the assets. Liquidation was his least favourite of the options. Beyond the physical assets, the company’s name, mailing list, products, and recipes would have some value. He found employee takeover intriguing, but they currently did not have any mechanism in place that would create the capital necessary to guarantee an employee buyout. The employees would have to pool their own money. Ron was not sure that any of them had it. His favourite scenario was finding a couple in their mid-30s who were interested in the business. The situation was reminiscent of their situation 35 years ago. He thought they could work with the new partners and train them on the intricacies of the business, while retaining the culture of the organization and protecting the employees’ future. Ron expanded on this thought:

They would have to put some skin in the game, maybe $100,000. The money would go into the business rather than our pockets. We could use the money to make some necessary improvement to operations, improve efficiencies, and do some concerted marketing. The idea would be to grow the business far enough, to raise sufficient funds in the future to buy us out.

Ron was also considering the possibilities for expansion on their own. He thought this would be viable if Jacki and he continued to stay active in the business for another 5-10 years. That prospect did not seem unreasonable. They were both in good health and Ron’s parents lived actively, well into their 90s. Ron described a recent conversation he had with Kathy.

I was talking to Kathy about our loan and that fact that the balloon payment was due soon. I was thinking about our options. The current loan is at a variable rate, and I would like a fixed interest rate on the next loan. We could get a loan to pay off our existing debt and then get some additional capital. Possible growth avenues included improving the pack and ship infrastructure and upgrading some equipment. I created a one-page business statement, gave it to the bank, and asked them to give me a quote for rolling over the current balance, consolidating two other loans, and adding $90,000 for improvements. Ultimately, as the people responsible for repaying the loan, we need to decide whether, at our ages, we want to take on that added liability. If we were interested in getting out, we would not do any of that. We would preserve capital, cut expenses, and improve the bottom line to make it attractive for investors. We are healthy enough that we have the option to try to expand.

Whether they decided to continue on their own or with partners, Ron believed that some progress needed to be made in building the confidence of his current staff to act independently and take on some of his own responsibilities. He explained:

About a month ago, I get a call from Ben. “We had an accident.” I was immediately concerned that someone was hurt and asked what happened. Ben explained that they lost track of the temperature of the toffee, and it overcooked. I replied, “that’s not an accident, it’s a mistake.”’ He wanted to know if they should make another batch. I say, “Is Debby expecting it?” and he replies, “Yes.” I say, “well there’s your answer.” These are good people, but they don’t feel confident making decisions themselves. Here is another story. Jacki and I had some things we had to do a week and a half ago, and it put a huge burden on Debby, who had to deal with the Valentine’s Day packaging, plus the end of our January sale. In the last few days of January, the orders just bombed in, and there were a couple of hiccups. So, I go over to Debby the next day and say, “a little stressed out?” I suggested to her that, if this situation occurred again in the future, she could ask Ben to give her Emily for a few days or talk to Kathy to see whether they had to process all of these orders immediately. I realized that I had never given Debby the authority to make decisions like these. This was a learning experience for both of us. I don’t want people to be stressed over their jobs.

Ron retained responsibility for much of the strategizing, planning, marketing, and management of operations. He suggested that he would like to give that up, and was planning to ask Debby if she would take on a salaried position as director of operations and assume some of those responsibilities. He thought that would free him up for other activities.

I still want to make candy. Kristin does all of the hand dipping now, all the clusters. She’s great, I can just help out. Kathy does all of the bills. Ben and Debby handle operations. What I would love to do is just the back-end planning, and then be on the road again selling. I’d be happy hopping in the car with $5,000 worth of Buttercrunch and heading off to do a show.

Exhibits

Exhibit 1 – Income Statement

| Income Line Items | 2012 | 2011 | 2010 | 2009 |

|---|---|---|---|---|

| Sales | blank | blank | blank | blank |

| Retail | 457,370 | 403,883 | 382,995 | 382,078 |

| Mail Order | 346,848 | 373,849 | 330,145 | 277,223 |

| Total Sales | 804,218 | 777,732 | 713,140 | 659,301 |

| Cost of Goods Sold | blank | blank | blank | blank |

| Retail | 395,669 | 301,499 | 302,566 | 301,675 |

| Mail Order | 213,963 | 262,237 | 213,557 | 200,876 |

| Total Cost of Goods Sold | 609,632 | 563,736 | 516,123 | 502,551 |

| Operating Expenses | blank | blank | blank | blank |

| Advertising | 32,241 | 25,830 | 21,850 | 16,123 |

| Employee Benefits | 11,706 | 10,296 | 8,650 | 8,650 |

| Payroll Taxes | 4,438 | 5,552 | 4,538 | 4,538 |

| Officer Salaries | 53,500 | 68,193 | 62,093 | 56,340 |

| Other Operating Expenses | 67,367 | 68,679 | 63,588 | 39,612 |

| Total Operating Expenses | 169,252 | 178,550 | 160,719 | 125,263 |

| Income from Operations | 25,334 | 35,446 | 36,298 | 31,487 |

| Gain (loss) in Sale of Fixed Assets | (2,304) | 5,000 | 6,685 | 950 |

| Interest Income (Expense) | (5,349) | (6,789) | (8,099) | (11,799) |

| Total Income from Operations | 17,681 | 33,657 | 34,884 | 20,638 |

| Income Taxes—Current | 250 | 250 | 250 | 250 |

| Income Taxes—Deferred | 8,364 | 4,411 | 7,591 | 9,293 |

| Net Income | 9,067 | 28,996 | 27,043 | 11,095 |

Source: Independent auditor’s reports prepared for Mother Myrick’s Confectionery for 2009 to 2012.

Exhibit 2 – Balance Sheet: Assets and Liabilities

| Balance Sheet Line Items | 2012 | 2011 | 2010 | 2009 |

| ASSETS | blank | blank | blank | blank |

| Current Assets | blank | blank | blank | blank |

| Cash | 97,105 | 79,281 | 63,673 | 55,401 |

| Inventory | 70,362 | 59,517 | 58,488 | 59,870 |

| Deferred Tax Asset | 6,533 | 14,895 | 19,308 | 26,899 |

| Total Current Assets | 174,000 | 153,693 | 141,469 | 142,170 |

| Property, Plant, and Equipment | blank | blank | blank | blank |

| Leasehold Improvements | 138,927 | 138,927 | 138,649 | 131,859 |

| Equipment | 297,155 | 293,179 | 293,872 | 302,535 |

| Furniture and Fixtures | 97,944 | 107,394 | 107,394 | 115,227 |

| Vehicles | 8,250 | 8,250 | 8,250 | 8,250 |

| Total Property Assets | 542,276 | 547,750 | 548,165 | 557,871 |

| Less Accumulated Depreciation | 426,397 | 413,175 | 404,294 | 398,341 |

| blank | 115,879 | 134,575 | 143,871 | 159,530 |

| Other Assets | 1,500 | 3,000 | 3,000 | 3,000 |

| Total Assets | 291,379 | 291,268 | 288,340 | 304,700 |

| LIABILITIES AND SHAREHOLDERS’ EQUITY | blank | blank | blank | blank |

| Current Liabilities | blank | blank | blank | blank |

| Notes Payable—Current Portion | 27,740 | 31,600 | 18,000 | 17,074 |

| Loans Payable—Credit Cards | 34,735 | 12,220 | 7,061 | 16,306 |

| Accounts Payable | 13,725 | 10,547 | 5,450 | 4,011 |

| Accrued Wages | 9,092 | 8,772 | 6,786 | 2,675 |

| Sales Tax Payable | 835 | 270 | 296 | 138 |

| Corporation Taxes Payable | 250 | 250 | – | 250 |

| Total Current Liabilities | 86,377 | 63,659 | 37,593 | 40,454 |

| Long-Term Liabilities | blank | blank | blank | blank |

| Notes Payable—Non-Current Portion | 77,542 | 103,745 | 193,890 | 214,786 |

| Loans Payable—Officers | 89,945 | 95,416 | 57,405 | 77,051 |

| Total Long-Term Liabilities | 167,487 | 199,161 | 251,295 | 291,837 |

| Shareholders Equity | blank | blank | blank | blank |

| Common Stock, No Par Value | 28,387 | 28,387 | 28,387 | 28,387 |

| Retained Earnings | 9,128 | 61 | (28,935) | (55,978) |

| Total Shareholders Equity | 37,515 | 28,448 | (548) | (27,591) |

| Total Liabilities and Shareholders’ Equity | 291,379 | 291,268 | 288,340 | 304,700 |

Note: The amounts listed as “Loans Payable – Credit Cards” reflect short-term interest-free credit card financing used by the proprietors to improve cash flow.

Source: Independent auditor’s reports prepared for Mother Myrick’s Confectionery for 2009 to 2012.

Exhibit 3 – One-Page Business Plan

MOTHER MYRICK’S CONFECTIONERY

Fine Chocolates & Cakes

January 2013

Background:

The fudge Factory, Inc. had been in original ownership since its formation in 1977. Located in Manchester Center, Vermont for the past 35 years, the company is reorganized as a manufacturer of upscale award-winning chocolates and cakes that are sold through its retail store in Manchester and online to its mail-order customers. In addition to the retail location, the company operates a 4000 sq. Ft. Production and mail order fulfillment facility in the Manchester Valley Industrial Park. The company employs 12 people year-round (16 during the Christmas season). Since the recession of 2008, the company has enjoyed consistent sales growth each year. Approximately 55% of the company’s revenues are generated at the retail store and 45% through its direct marketing channels.

Purpose of this Submission:

The company is at capacity to meet peak seasonal demands from its web and catalog division. This also impacts the company’s ability to meet the demands of its retail division during high-demand periods. This is the right time for the company to seek funds for capital improvements while consolidating its outstanding debt.

The company has a term loan with Berkshire Bank that matures in February 2013 with an outstanding balance of $73,628. The company is seeking funds to retire that loan, pay down two smaller high-interest loans totaling $12,000, and seeks additional capital of $90,000 to purchase and upgrade manufacturing and packaging equipment along with leasehold improvements to its pack and ship facility.

Funds will be allocated as follows:

| Item | Amount |

|---|---|

| Chocolate and baking processing equipment | $65,000 |

| Packaging equipment | $9,000 |

| Pack/Ship leasehold improvements | $10,000 |

| Software and Server upgrades | $6,000 |

| Berkshire Bank loan | $73,628 |

| Loan payable A. Verdi | $8,000 |

| Loan payable F. Baker | $4,000 |

| $175,638 |

Encl.

Fudge Factory, Inc. 2010 and 2011 Financial Statements

Fudge Factory, Inc. Federal tax returns FYE 4/30/2011 and 2012

Principal’s personal financial statement dated 1/15/2013

Principal’s Federal tax returns for the years 2010 and 2011

P.O. Box 115 – Manchester Center, Vermont – 05255

Phone: 802-362-2576 Fax: 802-362-6001 E-mail: ron@mothermyricks.com

www.mothermyricks.com

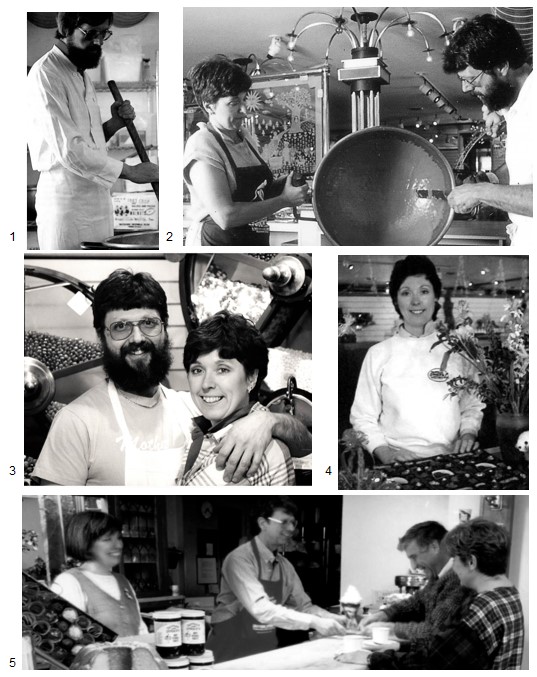

Exhibit 4 – Jacki and Ron Mancini Early Years

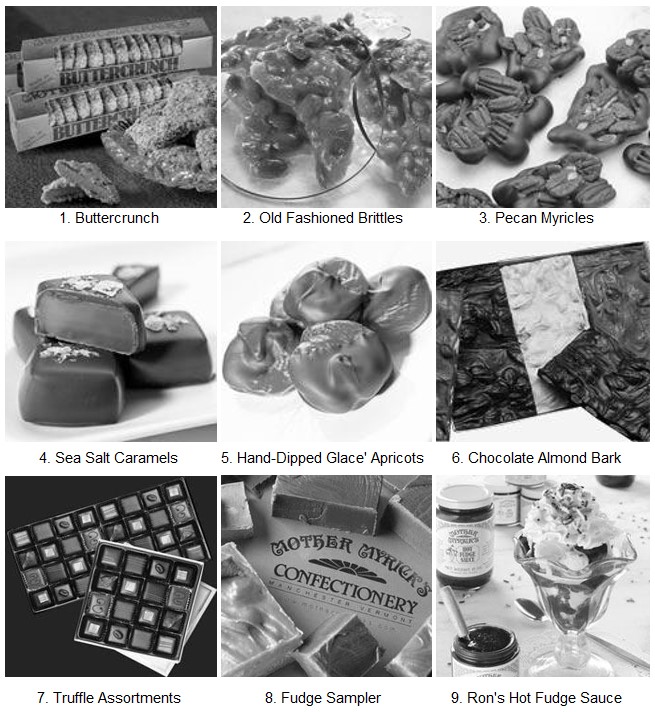

Exhibit 5 – Mother Myrick’s Candies, Chocolates, and Fudge

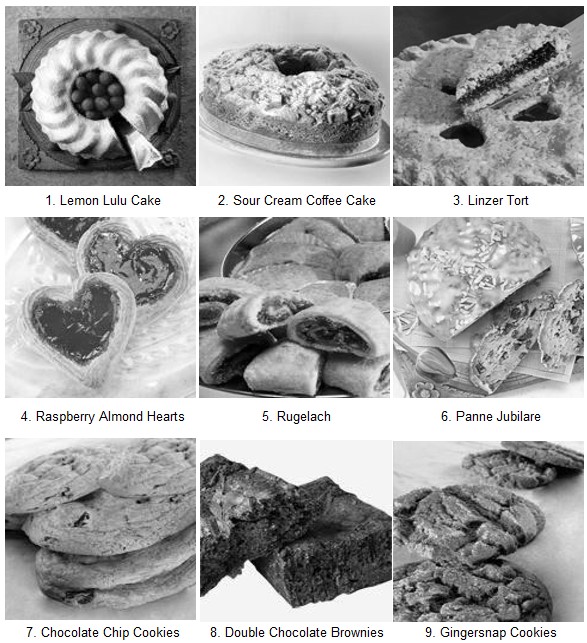

Exhibit 6 – Mother Myrick’s Bakery Favourites

Exhibit 7 – Mother Myrick’s Proprietors Jacki and Ron Mancini with Pies at the Retail Location

Exhibit 8 – Candy Kitchen and Shipping Area, February 2013 Plant Visit

Image Descriptions

Exhibit 4 – Jacki and Ron Mancini Early Years

A photo collage of five black and white images:

- Top left: Man stirring a large pot.

- Top right: Woman and man hold the large bowl and scrape out the contents.

- Middle left: Man and woman with arms around each other, looking at the camera and smiling.

- Middle right: Woman posing with a box of chocolates, looking at camera and smiling.

- Bottom: A woman and man behind the counter serving two customers, a man and a woman, with an ice cream sundae.

Exhibit 5 – Mother Myrick’s Candies, Chocolates, and Fudge

A photo collage of three rows of three images each showing close-ups of the following products:

- Buttercrunch

- Old fashioned brittles

- Pecan Myricles

- Sea Salt Caramels

- Hand-dipped Glace Apricots

- Chocolate Almond Bark

- Truffle Assortments

- Fudge Sampler

- Ron’s Hot Fudge Sauce

Exhibit 6 – Mother Myrick’s Bakery Favourites

A photo collage of three rows of three images each showing close-ups of the following products:

- Lemon Lulu Cake

- Sour Cream Coffee Cake

- Linzer Tort

- Raspberry Almond Hearts

- Rugelach

- Panne Jubilare

- Chocolate Chip Cookies

- Double Chocolate Brownies

- Gingersnap Cookies

Exhibit 8 – Candy Kitchen and Shipping Area, February 2013 Plant Visit

Three black and white photos show 1) at the top, the conveyer belt, 2) at the bottom left, the cooling rack in the foreground, and small worktables in the background, and 3) at the bottom right, the upright freezer with sink station to the right.

References

Barry Callebaut. (2023). Products. https://www.barry-callebaut.com/en-CA/manufacturers/product-filter.

Boehm’s Candies. (n.d.). Shop. https://boehmscandies.com/store/

Burr & Burton Academy. (n.d.). About: BBA by the numbers. http://www.burrburton.org/

Companies and Markets. (2013). U.S. confectionery market to reach a value of 37 billion by 2017. Companies and Markets. http://www.companiesandmarkets.com/News/Food-and-Drink/US-confectionery-market-to-reach-a-value-of-37-billion-by-2017/NI7576.

Consumer Financial Protection Bureau. (2020, September 9). What is a balloon payment? When is one allowed? https://www.consumerfinance.gov/ask-cfpb/what-is-a-balloon-payment-when-is-one-allowed-en-104/

Equinox. (n.d.) The Equinox story: A living legend, still evolving. Equinox Golf Resort and Spa. https://www.equinoxresort.com/vt_resort/history/

Franchise Help. (2013). Chocolate industry and analysis – 2013. Retrieved August 17, 2013, from http://www.franchisehelp.com/industry-reports/chocolate-industry-report

Freestyle Solutions. (n.d.). Inventory, order & customer management software. http://www.dydacomp.com/Products/Overview

Mintel. (2013). Market research report, chocolate industry – US – April 2013. Retrieved August 17, 2013, from http://store.mintel.com/chocolate-confectionery-us-april-2013

Mother Myrick’s Confectionery. (2023). About us. http://www.mothermyricks.com/aboutus

Orvis. (2023). About the Orvis company. https://www.orvis.com/about-us.html

Retail Confectioners International. (n.d.). Retrieved June 20, 2013, from http://www.retailconfectioners.org

Town of Manchester. (n.d.). Town of Manchester history. Retrieved June 13, 2013, from http://www.manchester-vt.gov/content/town-manchester-history

World Cocoa Foundation. (2011). Economic profile of the U.S. chocolate industry. https://www.worldcocoafoundation.org/wp-content/uploads/Economic_Profile_of_the_US_Chocolate_Industry_2011.pdf

Download a PDF copy of this case [PDF].

Read the Instructor’s Manual Abstract for this case.

How to cite this case: Thurston, P.W., Eddy, E.R. & Robeson, D.C. (2023). Mother Myrick’s Confectionery. Open Access Teaching Case Journal, 1(1). https://doi.org/10.58067/dbbx-c736

The Open Access Teaching Case Journal is a peer-reviewed, free to use, free to publish, open educational resource (OER) published with the support of the Conestoga College School of Business and the Case Research Development Program and is aligned with the school’s UN PRME objectives. Visit the OATCJ website [new tab] to learn more about how to submit a case or become a reviewer.

- Mother Myrick’s Confectionery, n.d. ↵

- Manchester is primarily a tourist community, offering visitors something for all four seasons including fall foliage, skiing, fishing, a host of summer activities, and outlet shopping year-round. Manchester is the home of the Charles F. Orvis Company, maker of quality fishing gear and outdoor apparel since 1856 and of the Equinox Hotel, founded by Charles’ brother, Franklin,in 1853 (Equinox, n.d.; Orvis, 2023; Town of Manchester, n.d.). ↵

- Mother Myrick’s Confectionery, 2023. ↵

- A balloon payment is a larger-than-usual one-time payment at the end of the loan term (Consumer Financial Protection Bureau, 2020). ↵

- Boehm’s Candies, n.d. ↵

- Retail Confectioners International is a trade association that has served the chocolate and confectionery industry since 1917 (Retail Confectioners International, n.d.). ↵

- Barry Callebaut offers cocoa and confectionery products and customized services to the food manufacturing industry (Barry Callebaut, 2023). ↵

- Mother Myrick’s Confectionery, 2023. ↵

- Burr and Burton Academy is an independent, coeducational New England secondary school situated at the foot of Mt. Equinox Mountain and overlooking picturesque Manchester Village (Burr & Burton Academy, n.d.). ↵

- Companies and Markets, 2013. ↵

- Companies and Markets, 2013. ↵

- Mintel, 2013. ↵

- World Cocoa Foundation, 2011. ↵

- Franchise Help, 2013. ↵

- Freestyle Solutions, n.d. ↵

- J. Mancini, personal communication, 7 February, 2013. ↵