Part 7 – Refrigeration Compressors

Monitoring And Control Systems

The type of system used depends on the type of compressor used, the size of the system, and the age of the equipment. Control systems have 3 basic functions:

- Control

- Protection

- Monitoring

There are four types of regulation: start-stop control, variable speed control, constant speed control, and dual control. Let’s take a look at each in more detail.

Activity: Types of Regulation

Click on the accordion tabs to learn more about the four types of regulation.

Compressor Unloading

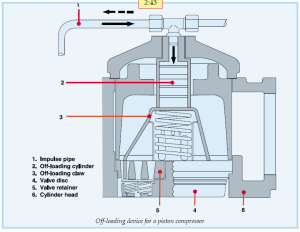

Piston compressors can be effectively relieved by mechanically forcing the intake valves to the open position. Air is then pumped out and in with minimal energy losses as a result

often lower than 10% of the loaded shaft power.

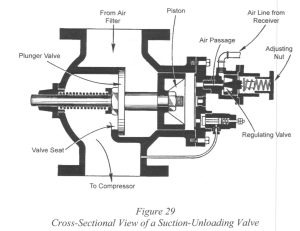

Alternate methods of unloading a reciprocating compressor are:

- A suction-line unloading valve

- Suction and discharge unloaders

- Inlet valve kept closed

- Adjustable compression stroke

- Variable clearance volume

Methods of controlling a dynamic compressor are: Throttling intake. Inlet guide vanes, Outlet guide vanes, Pressure relief, and speed Control.

Unloading devices are actuated either electrically, by centrifugal force, or by oil pressure generated by the compressor lubricating oil pump.

Control Systems

These basic systems have electric relays and pneumatic controls for controlling compressor valves and stopping and starting. Monitoring these units is usually done with pressure and temperature gauges. Protective switches and devices may be mechanically or pneumatically activated. Extensive control systems use microprocessors. Microprocssors provide instantaneous information retrieval and equipment control. They may be tied into a larger plant control system