Part 6 – Absorption Refrigeration

Absorption System Startup

Startup and operating procedures for an absorption unit – startup varies depending on unit.

Seasonal Prestart Service locks out all sources of energy, cleans all cooling and chilled water strainers and the cooling tower sump, and checks the lubricant in circulating pumps and cooling tower fans. Check pumps and fans for free rotation.

Open necessary valves in the cooling and chilled water systems. If the systems were drained during shutdown, fill them with clean water. Vent all the air from the systems. It may take one or two days of circulation before all the air is removed. Add the required water treatment chemicals, check the magnetic strainers in the absorption unit pump motor cooling circuit, and clean them. If the absorption unit is equipped with a mechanical purge system, check the purge pump and if the refrigerant float chamber is empty, connect a temporary clean water supply for pump motor lubrication and cooling.

Seasonal Startup

Here are the following steps of a seasonal startup:

- Open the supply valve to the pneumatic control system. Check the air supply pressure. It should not exceed 140 kPa.

- Place the condenser water pump and cooling tower fan switches in the automatic position.

- Make sure the starting switches are in the OFF position and then close the main breakers.

- Open the manual shutoff valve in the steam or hot water supply line to the unit. If a temporary water supply is used for the unit pump motor circuit, open the supply valve. Limit the water pressure to 35 kPa.

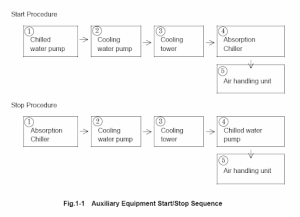

- Start the auxiliaries and the absorption unit following the procedure recommended by the manufacturer.

- When the float chamber has filled, stop the unit.

- Disconnect the temporary water supply to the pump lubrication and cooling circuit. Open the valves in the regular supply circuit.

- Restart the unit.

- After the absorption unit has been operating for approximately 30 minutes, start the purge unit. Check all temperatures, pressures, and flows. Enter the required data on the log sheet.

- Add octyl alcohol to the unit as recommended.

Seasonal Shutdown

Here are the following steps of a seasonal shutdown:

- Turn the unit switch on the control panel to OFF and allow the machine to complete the dilution cycle.

- Stop the chilled water pump. This stops the cooling water pump and cooling tower fan.

- Close the manual steam or hot water supply valve.

- Open all disconnect switches.

- Turn off the air supply to the pneumatic control system.

- Drain the cooling water circuit.

- Service all the auxiliary pumps, the cooling tower, the fan, etc. Follow the manufacturer’s instructions.

- Service the purge pump (if so equipped).

Startup After Short Shutdown (Weekend or Less)

- Open the manual shutoff valve in the steam or hot water supply line.

- Start up the unit according to the manufacturer’s recommended procedure.

- Start the purge unit after operating for 30 minutes.

Shutdown for Short Period (Weekend of Less)

Perform steps 1, 2, and 3 of the seasonal shutdown procedure.

Temperature Control

During operation, temperature control controls the flow of steam or hot water to the concentrator – fairly constant chilled water temperature is maintained over a wide range of load conditions.

When the chilled water temperature drops below the temperature control setting temperature below setpoint causes the switch to open stopping the condenser water pump and de-energizing the cooling tower fan starter, the time delay relay, and the solenoid air valve. The fan stops and the flow of steam or hot water to the concentrator is cut off. Even though the time delay relay has been de-energized, its contacts remain closed for another four minutes providing continued operation of the unit pumps so that the unit completes its dilution cycle.

Chiller Start Up

Once the chiller has started up, it’s important to keep an eye on the following:

- Suction pressure

- Discharge pressure

- Check compressor for flood back

- Check the entering and leaving water temperature of the chiller

- Check the entering and leaving water temperature of the condenser