Part 5 – Cooler and Air Dryers

Compressor Cooling

Compression process causes an increase in the temperature of the compressed fluid. Cooling during the compression process improves the efficiency of compression. While cooling after compression reduces the final discharge temperature.

Cooling During Compression

Air cooling is done most effectively during compression. Small and medium-size single-acting air compressors use fins on the cylinder walls and cylinder heads. Water jackets surround cylinders and heads in large compressors, double-acting compressors, multi-stage compressors, and small and medium vertical single-acting compressors.

A small percentage of the total volume of air being compressed comes into contact with the cooled surface of the cylinder. This limits removal of all the heat during the compression stroke and thus limits the operating temperature of the cylinder walls and head. As water circulates, it absorbs about 15 % of the heat generated during compression.

Types of Cooling Systems

1) Open system without circulating water

Water comes from the municipal water mains, a lake, a stream, or a well and is used to cool the compressor. The water us then discharged as waste water. The System should be controlled by a thermostat which functions to maintain the desired temperature, and governs water consumption.

2) Open system with circulating water

Cooling water from the compressor is re-cooled in a cooling tower.

3) Closed system

The same water circulates between the compressor and some form of cooler. Cooler is cooled either by another water circuit or the surrounding air. When the water is cooled against another water circuit a flat heat exchanger is used.

4) Air Cooling After Compression

Two distinct types of operation:

Intercooling- Cooling of the air back to its suction temperature between the stages of a multistage compressor.

Aftercooling- Final cooling of the air before it is delivered to the receiver or discharged through distribution lines.

Intercoolers

- Air cooled

- Have one or more straight, curved or coiled sections of finned tubing between headers

- Use fans to direct air over fins and coils

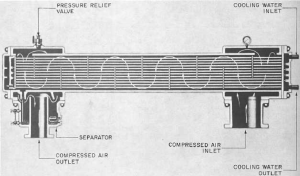

- Water-cooled

- Often shell and tube exchangers with straight tubes in a cylindrical shell.

- Baffle plates direct the gas flow across the tubes.

- Intercoolers

- Drains on intercoolers remove the water condensed from air after cooling.

- Usually the intercooler is not sized to cool the air enough for the moisture to condense.

- Exceptions are low ambient temperatures, or during startup and shutdown conditions.

If the compressed air temperature drops below the dew point, the water finds its way to the bottom of the intercooler shell and to the drain. In a two-stage compressor taking in air at atmospheric pressure, 20°C and 75% relative humidity, and a delivery pressure of 800 kPa gauge

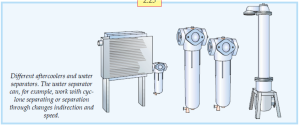

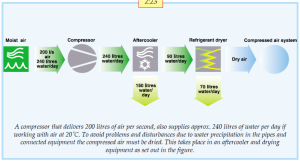

Aftercoolers use water as the cooling medium. They are used to cool the compressed air prior to its delivery either to the point of use or to the receiver. The temperature of the compressed air is reduced to the existing atmospheric temperature or below. A water separator may be used.

It’s important that the water be separated from the air and periodically drained. Compressed gas streams for process use may not require cooling.

Water in the air can cause water hammer, ice formation in cold weather, or rust and corrosion in the piping and the equipment using the air.

Air Drying

Air Dryers are the instrument air requires the delivery air be as dry as possible. There are three main types of dryers:

- Membrane

- Desiccant

- Refrigerant

Membrane Driers

Image Gallery: Membrane Dryer

Click the arrows to view images of membrane dryers.

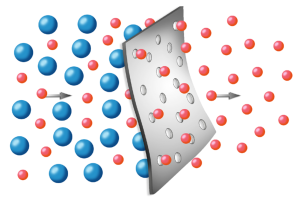

Membrane driers are best suited to small applications. Allow drying to a dew point of between 4°C to -40°C. They consist of microscopic tubes bundled in a larger tube. Compressed air stays inside the small membrane tubes, while purge air is supplied to the larger tube. Water vapour passes through the membrane into the purge air. Finally, the purge air sweeps away moisture that has passed through the membrane and is vented.

Membrane Dryer Process:

- Air passes through a high efficiency coalescing filter to remove oil and water droplets and particulate contamination.

- The water vapor in the compressed air is removed by the principle of selective permeation through a membrane

- Hollow membrane fibers are permeable only to water vapor.

- Compressed air passes through the center of these fibers.

- A small portion of the dry air (regeneration flow) is redirected along the length of the membrane fiber to carry away the moisture-laden air which surrounds the membrane fibers.

Warning: Membrane Driers will seal over if air is contaminated requiring the entire membrane assembly to be replaced. To remedy this, use a large amount of purge air, typically 20-40% of the compressed air. This process is expensive to operate. The benefit is that it is simple construction and minimal maintenance required.

Desiccant (Adsorption) Driers

Uses a dessicant to adsorb moisture from the compressed air. Can provide dew points of -20°C to -100°C.

Two methods of regeneration: Hot regenerative and Cold regenerative.

Let’s take a look at both in closer detail!

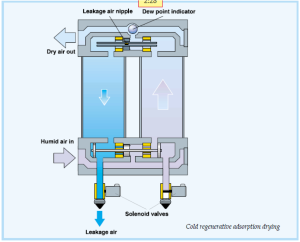

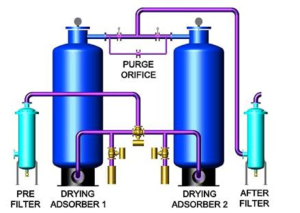

Cold (Heatless) Regenerative Type

Advantage: Heatless driers can be pneumatically controlled making them suitable for hazardous areas where electrical controls are not acceptable. Disadvantage: Usually about 15-18% of the compressed air is required for purge air – increased cost |

Hot Regenerative Type

|

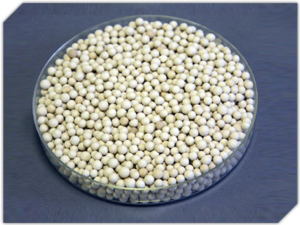

Desiccant Driers

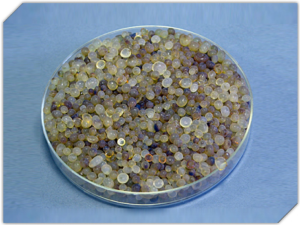

1) Silica Gel

The major desiccant used is Silica gel. This is because it is least expensive, retains large amounts of moisture ( will absorb 35% of its own weight in moisture – pick up rate) and can either a heatless or heat-activated process can be used with a reactivation temperature of 150°C.

2) Alumino-Silicate Gel

The other major desiccant used is Alumino-silicate gel . It is a more expensive desiccant but it is tolerant to liquid water. Use alumino-silicate gel as the first 1/3 of the desiccant and less expensive silica gel for the remainder.

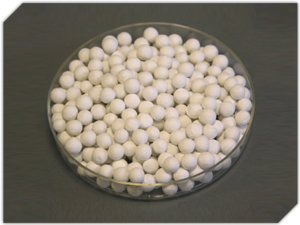

3) Activated Alumina

Activated alumina is a good all around desiccant which is quite tolerant of liquids. It is more expensive than alumino-silicate and silica gel but it allows the use of only one desiccant. It has a pickup rate of 16% which is lower than silica gel, but it is more stable. Activation can either a heatless or heat-activated process can be used with a reactivation temperature of 200°C.

4) Molecular Sieve

A molecular sieve provides the lowest dew points but is the most expensive. The pickup rate is about 18% and it is tolerant of liquids. Either a heatless or heat- activated process can be used with a reactivation temperature of 235°C.

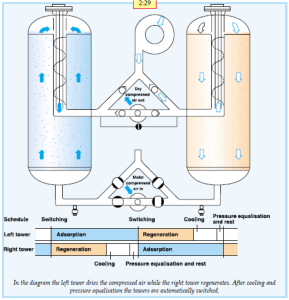

Desiccant Driers

Desiccant driers can either a heatless process or the application of heat can reactivate the desiccant – remove the moisture. Two towers are used with one tower used to dry the compressed air, while the other one is regenerating. When the drying tower becomes saturated, the compressed air is switched to the second tower while the first one is regenerated.

The heat can either be applied:

-

- Internally through a heater installed in the desiccant bed (where it is well protected in case it shorts out)

- Externally with a heated jacket around the tower and heat supplied electrically or with steam.

- The reactivation temperature depends on the type of desiccant.

- The amount of purge air required is about 3-8%.

Potential for fire with dessicant dryers when oil is carried over into the desiccant and collects over time. As the desiccant becomes coated with oil it losses its ability to adsorb water. If the heater thermostat fails and the temperature increases to 200-250°C, the oil may ignite resulting in a fire.

Refrigerated Driers

Refrigerated driers produce a dew point of about 2°C. They cool the compressed air through the use of heat exchangers that operate on a refrigeration cycle. These are suitable for large volume applications.

Image Gallery: Refrigerated Driers

Click the arrows to view images of refrigerated driers.

Over-compression is the easiest method to dry compressed air. Air is first compressed to a higher pressure than the intended working pressure. A concentration of water vapour increases. Air is then cooled, separating the water. Finally the air is allowed to expand to the working pressure. A lower PDP (Pressure Dew Point) is attained. This is only suitable for very small air flow rates, due to the high energy consumption.