Part 5 – Single Phase AC Motors

The following are types of single-phase AC motors are:

- Universal Motor

- Shaded-pole

- Split-phase

- Capacitor-start

- Repulsion-start

- Reluctance-start

Universal Motors

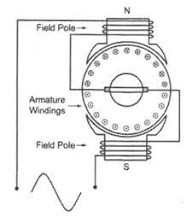

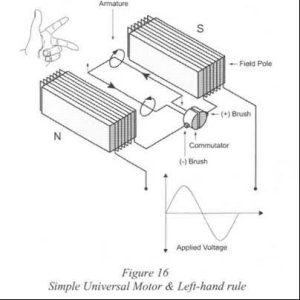

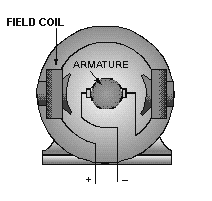

Universal motors operate on either single-phase AC or DC power. Normally made in sizes ranging from 1/200 to 1/3 horsepower and operates much like a series DC motor. Universal motors cannot use a permanent magnet to create the stator field and needs to reverse its magnetic polarity every half cycle of the mains. Voltage being fed to the commutator brushes is also changing polarity every half cycle in parallel with the field winding.

|

|

Activity: Universal Motor Stators

Click on the image hotspots to explore the functions of universal motor magnetic stators.

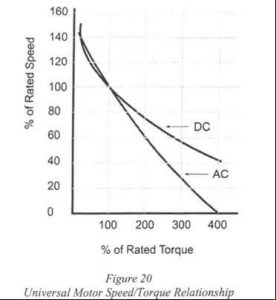

Universal motors operate at speeds between 3500 r/min and 20,000 r/min and the starting torque is high and speed decreases with load.

|

|

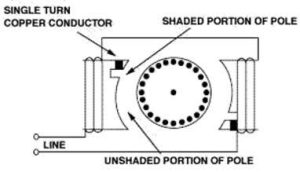

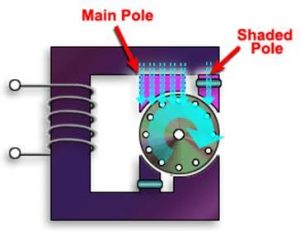

Shaded-Pole Motors

A shaded-pole motor is a type of AC single-phase induction motor. It is the simplest and least expensive type of single phase motor that is low starting torque and its use is limited to applications that require less than 3/4 horsepower, usually ranging from 1/20 to 1/6 horsepower. Shaded-poled motors have only one winding, no capacitor, and no starting switch, and are overall economical and reliable.

Activity: Shading-pole

Click on the image hotspots to explore the functions of a shading pole.

|

|

Split-Phase Motors

For split-phase motors, an auxiliary winding of much fewer turns of smaller wire is placed at 90o electrically to the main winding, it can start a single-phase induction motor. With lower inductance and higher resistance, the current will experience less phase shift than the main winding – about 30o of phase difference may be obtained. This winding produces a moderate starting torque and is disconnected by a centrifugal switch at 75% of synchronous speed. It serves well for motors up to 1/3 horsepower (250 watts) driving easily started loads. Split-phase motors contain start winding and run winding.

Run winding consists of a number of coils connected in series to form a set number of poles wound with a heavier gauge wire to reduce its resistance. Coils of the run winding are embedded deep into the slots of the iron stator core to increase its inductance. It has more turns than the start winding and this causes the run winding current to lag the applied voltage by a considerable phase angle.

The start winding consists of a number of coils connected in series to form the required number of poles that are wound with a finer gauge wire which increases its resistance. Start coils are placed nearer the surface of the stator core slots which reduces the inductance of this winding and causes the start current to be more in phase with the supply voltage than the run current in the run winding.

During the start period, both windings are connected in parallel across the applied voltage and the windings are wound on separate sets of field poles, which are set 90 electrical degrees apart.

Activity: Split-Phase Motors

Click the arrows to view images of split-phase motors.

Activity: Split-Phase Motors Speed/Torque

Click the image hotspot to learn about speed/torque for split-phase motors.

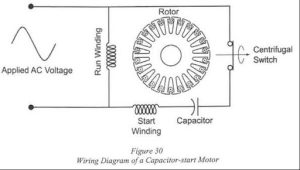

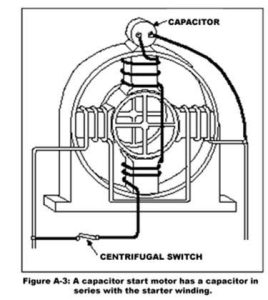

Capacitor-Start Motors

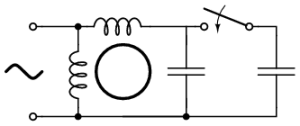

The capacitor-start motor is very similar to the split-phase motor but uses a capacitor to achieve a phase angle between the start winding and the run winding.

|

|

A capacitor is mounted on top of the motor frame and allows servicing of the capacitor as show below.

The use of a capacitor in the run winding also provides a greater phase angle than the split-winding arrangement and this results in greater starting torque. It also provides more than double the starting torque with one-third less starting current than the split-phase motor.

Activity: Capacitor-Start Motors Speed/Torque

Click the image hotspot to learn about speed/torque for capacitor-start motors.

Many appliances, such as washers and dryers, use capacitor-start motors. Domestic blower fans in furnaces also use capacitor start circuits for single-phase AC motors.

Capacitor Run Motor

Two windings are called the main and auxiliary windings. To start the motor, start with a relatively large capacitor for high starting torque and use a smaller value capacitor after starting to improve running characteristics while not drawing excessive current. A capacitor-run motor is used in larger-size motors.

A run capacitor ensures the correct phase displacement between the two currents in the windings and the start capacitor may be rated for intermittent duty, but the run capacitor must be designed for a continuous rating.

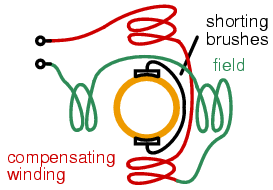

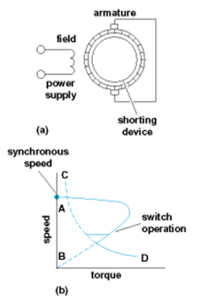

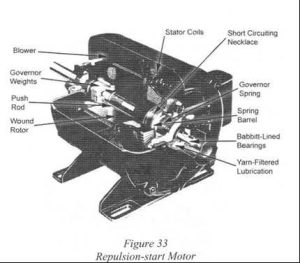

Repulsion-Start Motors

Repulsion-start motors have the highest starting torque of all single-phase induction motors. The stator is a single-phase AC and uses a commutator (like a DC motor) and brushes to start the motor. The rotor is constructed like a DC motor armature with a centrifugally controlled mechanism to short-circuit the commutator when the motor speed approaches synchronous speed.

|

|

The device known as a “short-circuiter”, can short out the commutator at the appropriate time and turn this winding into a rotating member that acts like the cast aluminum alloy rotors (squirrel-cage rotor) or the other “induction” motors. The repulsion Start motor has a winding with the ends of the coils attached to the commutator. Other single-phase motors have a rotor of cast aluminum alloy. High starting torque makes them suitable as drivers for compressors, reciprocating pumps, or grain silo unloaders.

Reluctance-Start (Switched Reluctance) Motors

A reluctance-start motor is a rotating electric machine where both the stator and rotor have salient poles. The stator winding is comprised of a set of coils, each of which is wound on one pole and the iron rotor with poles, but without any conductors. Based on the principle that a piece of iron will move to occupy the magnetic flux path of least reluctance.

Reluctance-start motors start as induction motor and locks into synchronism. The phases are connected to a single-phase supply. Electronic control equipment is required to switch when the phases are energized (hence the term switched reluctance motors). Similar to electronic vs. mechanical commutation and requires precise timing. Switching of the phases of the stator creates the revolving magnetic field and with the appropriate switching of applied power to the stator coils, the rotor can be made to rotate at any desired speed and torque.

Activity: Reluctance-Start Motors

Click the arrows to learn more about reluctance-start motors, rotors, and salient-pole stators.

Within this part, we have delved into the fascinating world of single-phase AC motors, exploring their diverse types and applications. Each motor type possesses unique characteristics, making it well-suited for specific tasks and environments. Let’s recap the key features of the single-phase AC motors we’ve discussed: the Universal Motor, Shaded-pole Motor, Split-phase Motor, Capacitor-start Motor, Repulsion-start Motor, and Reluctance-start Motor. Please review the following Word documents that show comparisons of motor types, AC motor family tree and electric motor troubleshooting.

Comparison of Motor Type [Word Doc]

AC Motor – Family Tree [Word Doc]

Electric Motor Troubleshooting Chart [Word Doc]