Part 3 – DC Generators

Types Of DC Generators

There are three main types of DC generators named according to the field and armature winding connections:

- Series-wound

- Shunt-wound

- Compound-wound

Series-Wound Generators

Series-wound generators have their field winding connected in series with the armature winding, utilizing low-resistance field coils made of large-diameter copper conductors. When the armature current rises, it leads to an amplified flux and consequently boosts the voltage at the generator’s output terminals.

Activity: Series-Wound Generator

Click the ticks on the slider to learn more about series-wound generators.

Shunt-Wound Generators

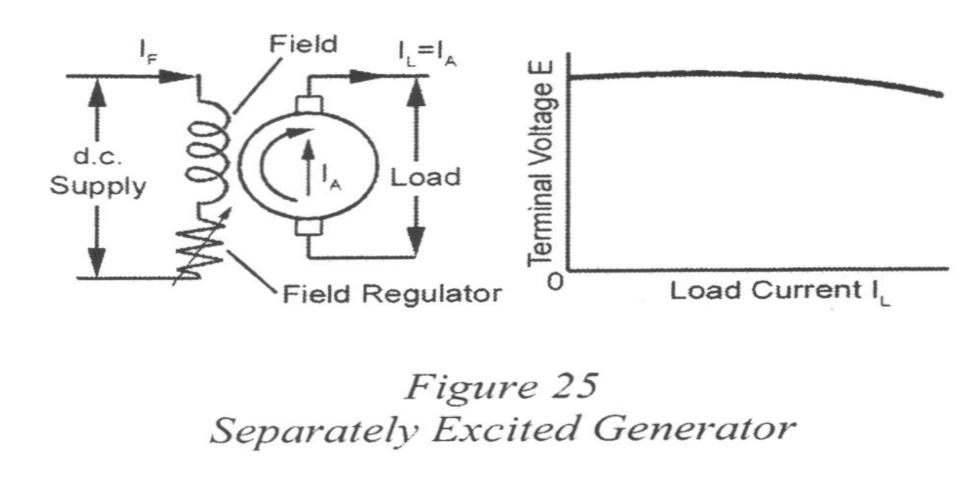

In shunt-wound generators, the field windings are arranged in parallel with the armature windings. To control the field strength, a field regulator or rheostat is employed. It’s worth noting that shunt windings experience a decrease in voltage as the generator load rises.

Activity: Shunt-Wound Generator

Click the arrows to see diagrams of shunt-wound generators.

Compound-Wound Generators

Compound-wound generators combine both series and shunt field windings, with one winding connected in parallel with the generator armature and the other in series. These windings are typically situated on the stator, allowing for a more versatile and controllable generator operation.

Activity: Compound-Wound Generators

Click the arrows to learn more about Compound-Wound Generators.

Increasing the number of turns in the series field winding results in a higher voltage output for the same current level.

Types of Compounded Generators

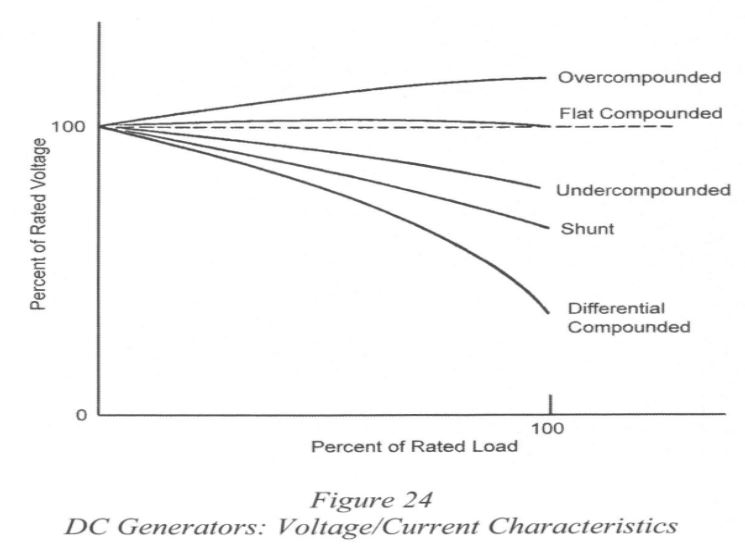

Over-compounded

More than the minimum number of turns required for a flat-compounded machine will cause the terminal voltage under load conditions to be greater than its no-load value.

Flat-Compounded Generator

In a flat-compounded generator, adding sufficient turns to offset voltage drop ensures a consistent terminal voltage from no-load to full-load conditions.

For compound-wound generators, there are different compounding methods. Under-compounding occurs when there are fewer turns than necessary.

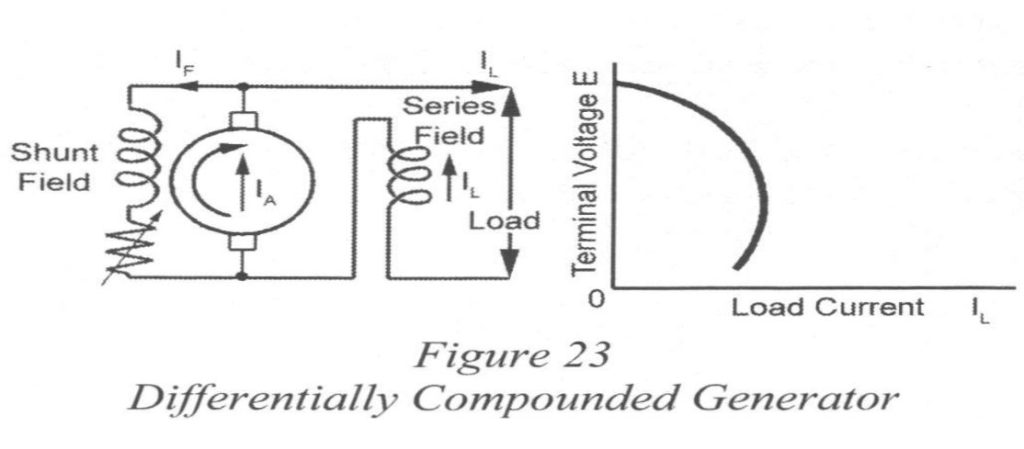

In differential compounding, the series magnetic field opposes the shunt field. When the armature current increases, there’s a corresponding decrease in flux and generated emf. This method is preferred when built-in overload protection is more valuable than maintaining a fixed voltage.

Over-compounded generators

- Used when the power is transmitted over long distances.

Flat-compounded generators

- Used when an unvarying voltage is required and the distance of transmission is short.

Shunt and Under-compounded generators

- More stable for parallel operation than flat and over-compounded machines.

Differential-compounded generators

- Used when built-in overload protection is more desirable than a fixed voltage.

Compound-Wound Generators

- Differential generators supply electric winches and dredges, in which an overload or short circuit causes sufficient voltage drop to limit the magnitude of the current to a safe value.