2.1 Introduction

READ:

Chapter 11 John Pile, and Judith Gura. History of Interior Design. Wiley, 2014. https://archive.org/details/HistoryOfInteriorDesign/mode/2up

The Industrial Revolution marked a period of development in the latter half of the 18th century that transformed largely rural, agrarian societies in Europe and America into industrialized, urban ones. Goods that had once been painstakingly crafted by hand started to be produced in mass quantities by machines in factories, thanks to the introduction of new machines and techniques in textiles, iron making, and other industries. Fueled by the game-changing use of steam power, the Industrial Revolution began in Britain and spread to the rest of the world, including the United States, by the 1830s and ‘40s. Modern historians often refer to this period as the First Industrial Revolution, to set it apart from the second period of industrialization that took place from the late 19th to early 20th centuries and saw rapid advances in the steel, electric, and automobile industries.

(Excerpt From: https://boisestate.pressbooks.pub/thecreativespirit)

The rise of technology and industry

By the 1860s, iron cooking ranges had arrived in most middle-class kitchens. They were an immense improvement on the old open fires, since they had built-in ovens and tanks for heating water. In the bathroom, water could be heated by gas-powered ‘geysers’, which were terrifying to the user but a blessing to the maid who no longer had to carry bath water up the stairs.

In the City, the old coffee houses were replaced by modern offices, using the new telegraph system to trade worldwide. Women were taken on as ‘typewriters’ and telephonists (the telephone was invented in 1877).

In 1834 Fox Talbot invented ‘sun pictures’ as photographs were called at first. They became a popular craze. ‘Cartes de visite’, mounted portrait photographs about the size of a modern credit card and used as visiting cards, were sold everywhere. Portraits of the Queen and her husband and children were popular. For the first time, her subjects could see what their Queen looked like, and by the end of the century, a ‘pocket Kodak’ cost just over a pound.

The international pre-eminence of London was confirmed when in 1883 Greenwich Mean Time was adopted worldwide.

After the triumph of Mr. Jennings’s lavatories, at the Great Exhibition, public toilets known as ‘halting stations’ began to make a coy appearance in the streets. By 1852 there was one for men in Fleet Street and one for women in the Strand, but they were slow to spread. The design of lavatories caused much head-shaking, until Thomas Crapper developed his new improved model: ’a certain flush with every pull’.

The textile industry

Cotton needs a humid atmosphere, to keep the fibres pliable enough to twist into thread. The cotton industry settled in rainy Manchester for that reason, but the weaving and spinning sheds were still full of dust and fibres, which irritated and damaged the lungs of the operatives. The factories were tightly packed with moving machinery, without guards. There were moving belts everywhere which could catch a woman’s hair and scalp her. A worker who leaned over to adjust a spindle risked losing a finger or a hand, or worse. Children were employed to clear faults, and accumulated dust, from underneath the machines. They often lost concentration, or fell asleep, with terrible results. The appalling clatter of a weaving or spinning shed led to occupational deafness, that was taken for granted.

Cotton spinning and weaving had been mechanised since the 1790s, using water power. By 1870 steam power was general. If the power-driven shafts and belts were to be economically used, factory workers had to comply with ‘factory discipline’ imposed by the overseers. Gradually the old one-to-one relationship between piece-work weaver and ‘putter-out’ gave way to impersonal contracts of mass employment.

Leeds and Halifax remained the centres for worsted and woolen spinning and weaving. (Worsted is a cloth with a smooth surface, resistant to wear, used for men’s suitings. Woollen cloth has a softer ‘handle’. It is used for women’s fashions.)

Macclesfield became the new silk-weaving centre. Spitalfields in London still produced elaborately designed, beautiful, silk fabrics, but the market for them was shrinking. The chemical industry on Merseyside developed synthetic dyes which produced brighter colours than the old vegetable dyes. Magenta, a harsh purple, was a Victorian favourite.

Coke-Fueled Blast Furnace

The coke fueled blast furnace, made by Abraham Darby, is one of the many inventions that shaped the modern world. The blast furnace revolutionized the way that pig iron was melted down for the production of steel. It was also a much easier and more efficient way of producing steel. The blast furnace was created in 1709 as a way to use coke instead of charcoal, as a fuel.1 Charcoal was becoming increasingly scarce and as a result it was also becoming increasingly expensive. This increase in price caused the production of steel to slow. This increasingly difficult way to produce steel created a demand for a new, cost efficient way to make steel.

Abraham Darby, the creator of the coke fueled blast furnace, decided to settle his invention in the town of Coalbrookdale in Shropshire, England. Darby settled in Coalbrookdale because of its readily available supply of coal, which was one of the best options for making coke.

Blast furnaces revolutionized the production of steel.2 It allowed for a faster production as well as a better product to be produced. Due to the fact that the coke-fueled blast furnaces allowed for the furnace to maintain a hotter temperature for a longer time, the quality of the steel was finer. The invention of the coke-fueled blast furnace led to many other inventions that the Industrial Revolution is known for. The blast furnace allowed for steel structures to be made faster and cheaper, propelling the Industrial revolution.

First thing to explore is the substance that is called “coke”. What is it and how is it created. One particular source gives a great definition of what the substance is and how it is created. Coke is a solid residue remaining after certain types of bituminous coals are heated to a high temperature out of contact with air until substantially all of the volatile constituents have been driven off.3 The residue is chiefly carbon, with minor amounts of hydrogen, nitrogen, sulfur, and oxygen. Also present in coke is the mineral matter in the original coal, chemically altered and decomposed during the coking process.

The success of the blast of the blast furnace would continue to make great strides in creating new jobs.4 Abraham Darby would pass away in 1717, but would his business would be in good hands with his son Abraham Darby II who would discover a way to create better coke by burning coal in the ovens. With this discovery the iron quality was far more superior. The result would only continue to help the industry for many more years.

The thriving blast furnace industry, created a demand for many new jobs. It boosted the local economy by creating more jobs within the coal industry as well as in the steel producing industry. With the use of the blast furnaces, steel became a common good. The lower and middle classes could now afford steel goods, such as cookware and utensils that previously, only the upper classes could afford, due to the cost of the production of steel. The creation of the coke-fueled blast furnace created a bridge between the classes and gave them something in common.

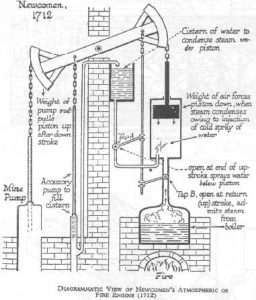

Steam Engine

The Newcomen and Watt steam engines had the biggest impact on mining. The Watt steam engine had drastically improved the efficiency of the Newcomen engine. This caused the demand of coal to go up. Due to the introduction of the steam engine and Britain’s coal deposits, the steam engine allowed the industry to flourish as Britain quickly industrialized before anyone else.7 In addition, the steam engine allowed the creation of mills and factories to produce mass amounts of goods faster than the labor of people. The Corliss steam engine had an impact on the textile industry, it allowed the mass production of textiles.8 Not only did the steam engine help produce mass amounts of goods but it also had an impact on boats and railroads.9 Although later in the industrial revolution, the steam engine was applied to locomotion. Application to locomotion would spark the rail era. The steam engine made transportation easier and quicker both on land and water. Along with the easier transportation, the opportunity for making profits increased.In the early 18th century, an Englishman named Thomas Newcomen invented the steam engine. Its sole purpose was to help lift water out from mines that were repeatedly waterlogged.5 Later, James Watt reworked the flaws of the Newcomen steam engine and made it more efficient in the process of how the condensation was carried.6 Watt’s partnership with Matthew Boulton, a British manufacturer, helped spread the work of the steam engine by solving problems of other businesses. With the creation of the steam engine, it made industrialization possible in Britain.

Spinning Jenny

The spinning jenny, invented by James Hargreaves in the mid-1760s, was one of the first inventions of the Industrial Revolution that got widespread use. The jenny was initially used in Britain and eventually spread to places like France after several improvements were made to its design. The jenny itself was an improvement of the older used spinning wheel, a commodity in many houses in Britain before the Industrial Revolution. The jenny’s job was to spin threads of cotton for widespread use and, unlike the spinning wheel, the jenny could be used in both small homes and industrial factories and varied in size from containing 12 to 120 spindles. The jenny was so convenient that it took substantially less labor than previous techniques and “raised the capital-labor ratio seventy-fold.”10 People were also frequently improving the jenny’s design and size, making it more efficient.

Still, in contrast to its many positives, the spinning jenny had its flaws, some of which were connected to its advantages. For example, since jenny’s were frequently being improved upon and changed, models quickly became outdated, much like modern IPhones and computers. Maintenance was also a factor in the frequently breaking jenny’s convenience and “annual maintenance costs equaled 10% of the purchase price of the machine”11. In many cases, however, the gain outweighed the losses and the spinning jenny was typically a wise investment.

The spinning jenny itself also drastically changed the lives of many women and children living during the Industrial Revolution. Since they had smaller and more agile hands, women and children were popular factory employees and often worked long hours, avoiding domestic duties and proper schooling. This fact brought about many issues on whether or not women and children, specifically girls, should work in factories. The Primary source by an unknown author touches on both the positives and negatives of girls working with spinning jenny’s in factories towards the beginning of the Industrial revolution in 1794. Click the link below and read the source carefully. Then answer the questions below to gain a better understanding on the author’s main points.

All of these inventions had a large impact on the Industrial Revolution. While this chapter focuses on three main inventions, it is important to remember that there were many more inventions that helped shape the modern world. Although all of these three inventions were instrumental to the progress of the industrial revolution. Without these inventions, we would not be as technologically advanced as we are now. As a society, we are constantly progressing and coming up with new inventions that shape society. What do you think is the most important invention to come out of the Industrial Revolution? What modern inventions do you think that we will look back on as the inventions that shaped the 21st century?

Ship building

Shipbuilding in England was forever changed by Brunel’s innovative Great Eastern, made of iron, driven by a propeller, and powered by steam, it was launched in Blackwall in 1858. By the end of the century shipbuilding and other heavy engineering had mostly moved to the north-east of England, the south of Wales and the Clyde in Scotland, where supplies of coal and iron were nearer.

Localised trades

In England, Sheffield was the center for cutlery, Leicester and Nottingham for hosiery, Northampton for shoes, Birmingham for metalworking, and small arms. Norwich had a small niche in exporting flat-packed kits of corrugated iron to the Empire, supplying the market for churches (known as ‘tin tabernacles’), millionaires’ mansions in South Africa, and summer residences in Darjeeling.

But many industries remained in London. Clerkenwell, long famous for precision watchmaking and scientific instruments, fizzed with new inventions. The finer components of small arms were made there, leaving mass production to Birmingham. Hiram Maxim developed his machine gun there, Marconi his electric telegraph, and Ferranti his dynamos. By 1901 almost half the 50,000 electrical apparatus makers of England and Wales worked in London. London factories supplied the endless market for that necessary status symbol, a piano.

Legislation

A series of Acts from 1819 onwards imposed on factory owners the duty to look after the health and safety of their workers. From 1850 mines were regularly inspected. By 1850, women, children and young people could work ‘only’ ten hours in a day, and ‘only’ between 6 am and 6 pm, so night work was now forbidden in factories, and from 1860, boys under 12 could not be employed in coal-mines. In 1850 mines were regularly inspected for compliance with lighting and ventilation regulations. But legislation does not always bring about reform. Conditions in coal-mines particularly, remained life-threatening until the next century.

The Truck Act of 1831 was a long-delayed attempt to outlaw the practice of paying workers, not with money, but with goods, or tokens exchangeable only at shops nominated by – and often owned by – the employer (‘truck’). Despite the Act, the practice was difficult to eradicate until the Mint put more low-value coinage into circulation.

Trade unions

For centuries, ‘combinations’ of working men had been viewed with suspicion, and were punishable by the criminal law. Gradually the climate of opinion changed. In 1834 the Tolpuddle Martyrs – farm labourers who had sworn an oath of loyalty to their labourers’ union – were sentenced to transportation to Australia. This outraged public opinion. They were pardoned two years later, and came home again; but their case had focused attention on the plight of unionised workers. The first effective Union, the Amalgamated Society of Engineers, was formed in 1851. The movement gathered strength, and other skilled workers formed unions. Peaceful picketing was allowed from 1859, and regular Trades Union Congresses began in 1868. Another strike caught public sympathy in 1888, when the ‘match girls’ of east London protested against the dangerous conditions of their work, and their pitiful level of pay. Their victory encouraged other unskilled workers to join in corporate action.

“The workshop of the world’

The Great Exhibition of 1851 caught England at the summit of its manufacturing boom. Innovative minds, sufficient capital, and skillful (often exploited) workforces all contributed to this success. The vast British Empire provided a captive market. But perhaps the Empire contained the germs of its own decline. The prosperity of its component parts encouraged aspirations to a separate identity, which led to its gradual dismembering in the next century. Meanwhile, the United States of America was rapidly outstripping England in technology.

- BBC – History – British History In Depth: The Blast Furnace Animation”. Bbc.co.uk, date accessed 11 May 2016, http://www.bbc.co.uk/history/british/victorians/launch_ani_blast_furnace.shtml.

- .“World Of Coke: Coke Is A High-Temperature Fuel”. Ustimes.com

- “Coke,” Encyclopædia Britannica Online, date accessed 11 May 2016, http://www.britannica.com/technology/coke

- “Iron & Steel Manufacture Industrial Revolution Significance.” Industrial Revolution, date accessed 11 May 2016, http://industrialrevolution.org.uk/iron-steel-industrial-revolution/.

- Richard Dennis Hoblyn, A Manual of the Steam Engine (London: Scott, Webster and Geary), chap. 2.

- Hoblyn, chap. 3.

- Alessandro, Bart, and Nick von Tunzelmann, “The early diffusion of the steam engine in Britain, 1700-1800: a reappraisal,” Cliometrica 5:3 (October, 2011): 314.

- Corliss Steam Engine Company, The steam engine as it was, and as it is… (Providence: Knowles, Anthony, 1857), chap. 1

- Hoblyn, chap. 9

- Robert C. Allen, “The Industrial Revolution in Miniature: The Spinning Jenny in Britain, France, and India ” working paper, last modified 2007, https://www.nuffield.ox.ac.uk/users/Allen/unpublished/jenny5-dp.pdf2007.

Attributions:

Excerpts from:

The Creative Spirit: 1550-Present by Elizabeth Cook is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

The rise of technology and industry by Liza Picard, The British Library is licensed under Creative Commons Attribution-4.0 International License

Foundations of Western Culture II, Spring 2016 by foundations.uwgb.org is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.