4 Operations and Production Management

Learning Objectives

Define operations management and discuss the role of the operations manager in a manufacturing company

Describe the decisions and activities of the operations manager in overseeing the production process in a manufacturing company

Explain how to create and use both PERT and Gantt charts

Explain how manufacturing companies use technology to produce and deliver goods in an efficient, cost-effective manner

Describe the decisions made in planning the product delivery process in a service company

List the characteristics that distinguish service operations from manufacturing operations and identify the activities undertaken to manage operations in a service organization

Explain how manufacturing and service companies alike use total quality management and outsourcing to provide value to customers

Introduction

The product development process can be complex and lengthy. It took sixteen years for Bob Montgomery and others at his company to develop the PowerSki Jetboard, and this involved thousands of design changes. It was worth it, though: the Jetboard was an exciting, engine-propelled personal watercraft – a cross between a high-performance surfboard and a competition water-ski/wakeboard that received extensive media attention and rave reviews. It was showered with honors, including Time magazine’s “Best Invention of the Year” award. Stories about the Jetboard appeared in more than fifty magazines around the world, and it was featured in several movies, over twenty-five TV shows, and on YouTube.

Montgomery and his team at PowerSki enjoyed taking their well-deserved bows for the job they did designing the product, but having a product was only the beginning for the company. The next step was developing a system that would produce high-quality Jetboards at reasonable prices. Before putting this system in place, PowerSki managers had to address several questions.

- What kind of production process should they use to make the Jetboards?

- How large should their production facilities be, and where should they be located?

- Where should they buy needed materials?

- What systems will be needed to control the production process and ensure a quality product?

Answering these and other questions helped PowerSki set up a manufacturing system through which it could accomplish the most important task that it had set for itself: efficiently producing quality Jetboards.

Operations Management in Manufacturing

Like PowerSki, every organization—whether it produces goods or provides services— sees Job 1 as furnishing customers with quality products. Thus, to compete with other organizations, a company must convert resources (materials, labor, money, information) into goods or services as efficiently as possible. The upper-level manager who directs this transformation process is called an operations manager. The job of operations management (OM) consists of all the activities involved in transforming a product idea into a finished product. In addition, operations managers are involved in planning and controlling the systems that produce goods and services. In other words, operations managers manage the process that transforms inputs into outputs.

Like PowerSki, all manufacturers set out to perform the same basic function: to transform resources into finished goods. To perform this function in today’s business environment, manufacturers must continually strive to improve operational efficiency. They must fine-tune their production processes to focus on quality, to hold down the costs of materials and labor, and to eliminate all costs that add no value to the finished product. Making the decisions involved in the effort to attain these goals is another job of operations managers. Their responsibilities can be grouped as follows:

- Production planning: During production planning, managers determine how goods will be produced, where production will take place, and how manufacturing facilities will be laid out.

- Production control: Once the production process is underway, managers must continually schedule and monitor the activities that make up that process. They must solicit and respond to feedback and make adjustments where needed. At this stage, they also oversee the purchasing of raw materials and the handling of inventories.

- Quality control. The operations manager is directly involved in efforts to ensure that goods are produced according to specification and that quality standards are maintained.

Let’s take a closer look at each of these responsibilities.

Planning the Production Process

The decisions made in the planning stage have long-range implications and are crucial to a firm’s success. Before making decisions about the operations process, managers must consider the goals set by marketing managers. Does the company intend to be a low-cost producer and to compete on the basis of price? Or does it plan to focus on quality and go after the high end of the market? Many decisions involve trade-offs. For example, low cost doesn’t normally go hand in hand with high quality. All functions of the company must be aligned with the overall strategy to ensure success.

With these thoughts in mind, let’s look at the specific types of decisions that have to be made in the production planning process. We’ve divided these decisions into those dealing with production methods, site selection, facility layout, and components and materials management.

Production-Method Decisions

The first step in production planning is deciding which type of production process is best for making the goods that your company intends to manufacture. In reaching this decision, you should answer such questions as:

- Am I making a one-of-a kind good based solely on customer specifications, or am I producing high-volume standardized goods to be sold later?

- Do I offer customers the option of “customizing” an otherwise standardized good to meet their specific needs?

One way to appreciate the nature of this decision is by comparing three basic types of processes or methods: make-to-order, mass production, and mass customization. The task of the operations manager is to work with other managers, particularly marketers, to select the process that best services the needs of the company’s customers.

Make-to-Order

At one time, most consumer goods, such as furniture and clothing, were made by individuals practicing various crafts. By their very nature, products were customized to meet the needs of the buyers who ordered them. This process, which is called a make-to-order strategy, is still commonly used by such businesses as print or sign shops that produce low-volume, high-variety goods according to customer specifications. This level of customization often results in a longer production and delivery cycle than other approaches.

Mass Production

By the early twentieth century, a new concept of producing goods had been introduced: mass production (or make-to-stock strategy), the practice of producing high volumes of identical goods at a cost low enough to price them for large numbers of customers. Goods are made in anticipation of future demand (based on forecasts) and kept in inventory for later sale. This approach is particularly appropriate for standardized goods ranging from processed foods to electronic appliances and generally result in shorter cycle times than a make-to-order process.

Mass Customization

There is at least one big disadvantage to mass production: customers, as one old advertising slogan put it, can’t “have it their way.” They have to accept standardized products as they come off assembly lines. Increasingly, however, customers are looking for products that are designed to accommodate individual tastes or needs but can still be bought at reasonable prices. To meet the demands of these consumers, many companies have turned to an approach called mass customization, which combines the advantages of customized products with those of mass production.

This approach requires that a company interact with the customer to find out exactly what the customer wants and then manufacture the good, using efficient production methods to hold down costs. One efficient method is to mass-produce a product up to a certain cut-off point and then to customize it to satisfy different customers.

Examples

Naturally, mass customization doesn’t work for all types of goods. Most people don’t care about customized detergents or paper products. And while many of us like the idea of customized clothes, footwear, or sunglasses, we often aren’t willing to pay the higher prices they command.

Facilities Decisions

After selecting the best production process, operations managers must then decide where the goods will be manufactured, how large the manufacturing facilities will be, and how those facilities will be laid out.

Site Selection

In site selection (choosing a location for the business), managers must consider several factors:

- To minimize shipping costs, managers often want to locate plants close to suppliers, customers, or both.

- They generally want to locate in areas with ample numbers of skilled workers.

- They naturally prefer locations where they and their families will enjoy living.

- They want locations where costs for resources and other expenses—land, labor, construction, utilities, and taxes—are low.

- They look for locations with a favorable business climate—one in which, for example, local governments might offer financial incentives (such as tax breaks) to entice them to do business in their locales. For example, an enterprise zone is an area in which incentives are used to attract investments from private companies.

Managers rarely find locations that meet all these criteria. As a rule, they identify the most important criteria and aim at satisfying them. In deciding to locate in San Clemente, California, for instance, PowerSki was able to satisfy three important criteria: (1) proximity to the firm’s suppliers, (2) availability of skilled engineers and technicians, and (3) favorable living conditions. These factors were more important than operating in a low-cost region or getting financial incentives from the local government. Because PowerSki distributes its products throughout the world, proximity to customers was also unimportant.

Capacity Planning

Now that you know where you’re going to locate, you have to decide on the quantity of products that you’ll produce. You begin by forecasting demand for your product, which isn’t easy. To estimate the number of units that you’re likely to sell over a given period, you have to understand the industry that you’re in and estimate your likely share of the market by reviewing industry data and conducting other forms of research.

Once you’ve forecasted the demand for your product, you can calculate the capacity requirements of your production facility—the maximum number of goods that it can produce over a given time under normal working conditions. In turn, having calculated your capacity requirements, you’re ready to determine how much investment in plant and equipment you’ll have to make, as well as the number of labor hours required for the plant to produce at capacity.

Like forecasting, capacity planning is difficult. Unfortunately, failing to balance capacity and projected demand can be seriously detrimental to your bottom line. If you set capacity too low (and so produce less than you should), you won’t be able to meet demand, and you’ll lose sales and customers. If you set capacity too high (and turn out more units than you should), you’ll waste resources and inflate operating costs.

Managing the Production Process in a Manufacturing Company

Operations managers engage in the daily activities of materials management, which encompasses the activities of purchasing, inventory control, and work scheduling.

Purchasing and Supplier Selection

The process of acquiring the materials and services to be used in production is called purchasing (or procurement). For many products, the costs of materials make up about 50 percent of total manufacturing costs. Not surprisingly, materials acquisition gets a good deal of the operations manager’s time and attention. As a rule, there’s no shortage of vendors willing to supply materials, but the trick is finding the best suppliers. Operations managers must consider questions such as:

- Can the vendor supply the needed quantity of materials at a reasonable price?

- Is the quality good?

- Is the vendor reliable (will materials be delivered on time)?

- Does the vendor have a favourable reputation?

- Is the company easy to work with?

Getting the answers to these questions and making the right choices—a process known as supplier selection—is a key responsibility of operations management.

e-Procurement

Technology has changed the way businesses buy things. Through e-procurement, companies use the Internet to interact with suppliers. The process is similar to the one you’d use to find a consumer good—say, a high-definition TV—over the Internet. To choose a TV, you might browse the websites of manufacturers like Sony then shop prices and buy at Amazon, the world’s largest online retailer.

If you were a purchasing manager using the Internet to buy parts and supplies, you’d follow basically the same process. You’d identify potential suppliers by going directly to private websites maintained by individual suppliers or to public sites that collect information on numerous suppliers. You could do your shopping through online catalogs, or you might participate in an online marketplace by indicating the type and quantity of materials you need and letting suppliers bid. Finally, just as you paid for your TV electronically, you could use a system called electronic data interchange (EDI) to process your transactions and transmit all your purchasing documents.

The Internet provides an additional benefit to purchasing managers by helping them communicate with suppliers and potential suppliers. They can use the Internet to give suppliers specifications for parts and supplies, encourage them to bid on future materials needs, alert them to changes in requirements, and give them instructions on doing business with their employers. Using the Internet for business purchasing cuts the costs of purchased products and saves administrative costs related to transactions. It’s also faster for procurement and fosters better communications.

Inventory Control

If a manufacturer runs out of the materials it needs for production, then production stops. In the past, many companies guarded against this possibility by keeping large inventories of materials on hand. It seemed like the thing to do at the time, but it often introduced a new problem—wasting money. Companies were paying for parts and other materials that they wouldn’t use for weeks or even months, and in the meantime, they were running up substantial storage and insurance costs. If the company redesigned its products, some parts might become obsolete before ever being used.

Most manufacturers have since learned that to remain competitive, they need to manage inventories more efficiently. This task requires that they strike a balance between two threats to productivity: losing production time because they’ve run out of materials and wasting money because they’re carrying too much inventory. The process of striking this balance is called inventory control, and companies now regularly rely on a variety of inventory-control methods.

Just-in-Time Production

One method is called just-in-time (JIT) production: the manufacturer arranges for materials to arrive at production facilities just in time to enter the manufacturing process. Parts and materials don’t sit unused for long periods, and the costs of “holding” inventory are significantly cut. JIT, however, requires considerable communication and cooperation between the manufacturer and the supplier. The manufacturer has to know what it needs and when. The supplier has to commit to supplying the right materials, of the right quality, at exactly the right time.

Material Requirements Planning

A software tool called material requirements planning (MRP), relies on sales forecasts and ordering lead times for materials to calculate the quantity of each component part needed for production and then determine when they should be ordered or made. The detailed sales forecast is turned into a master production schedule (MPS), which MRP then explodes into a forecast for the needed parts based on the bill of materials for each item in the forecast. A bill of materials is simply a list of the various parts that make up the end product. The role of MRP is to determine the anticipated need for each part based on the sales forecast and to place orders so that everything arrives just in time for production.

Graphical Tools: Gantt and PERT Charts

To control the timing of all operations, managers set up schedules: they select jobs to be performed during the production process, assign tasks to work groups, set timetables for the completion of tasks, and make sure that resources will be available when and where they’re needed. There are a number of scheduling techniques. We’ll focus on two of the most common—Gantt and PERT charts.

Example

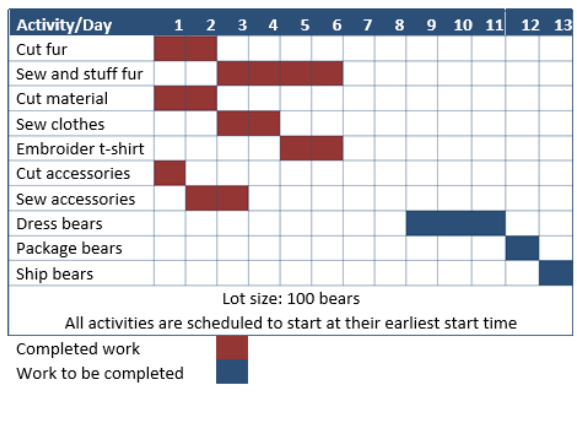

Gantt Charts

A Gantt chart, named after the designer, Henry Gantt, is an easy-to-use graphical tool that helps operations managers determine the status of projects. Let’s say that you’re in charge of making the “hiking bear” offered by the Vermont Teddy Bear Company. This is a Gantt chart for the production of one hundred of these bears. As you can see, it shows that several activities must be completed before the bears are dressed: the fur has to be cut, stuffed, and sewn; and the clothes and accessories must be made. Our Gantt chart tells us that by day six, all accessories and clothing have been made. The sewing and stuffing, however (which must be finished before the bears are dressed), isn’t scheduled for completion until the end of day eight. As operations manager, you’ll have to pay close attention to the progress of the sewing and stuffing operations to ensure that finished products are ready for shipment by their scheduled date.

A Gantt chart, named after the designer, Henry Gantt, is an easy-to-use graphical tool that helps operations managers determine the status of projects. Let’s say that you’re in charge of making the “hiking bear” offered by the Vermont Teddy Bear Company. This is a Gantt chart for the production of one hundred of these bears. As you can see, it shows that several activities must be completed before the bears are dressed: the fur has to be cut, stuffed, and sewn; and the clothes and accessories must be made. Our Gantt chart tells us that by day six, all accessories and clothing have been made. The sewing and stuffing, however (which must be finished before the bears are dressed), isn’t scheduled for completion until the end of day eight. As operations manager, you’ll have to pay close attention to the progress of the sewing and stuffing operations to ensure that finished products are ready for shipment by their scheduled date.

PERT Charts

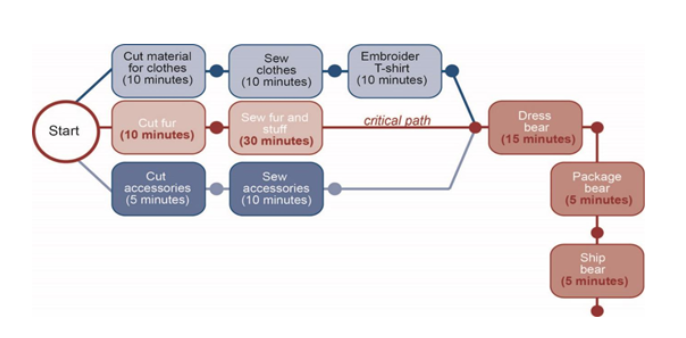

Gantt charts are useful when the production process is fairly simple and the activities aren’t interrelated. For more complex schedules, operations managers may use PERT charts. PERT (which stands for Program Evaluation and Review Technique) is designed to diagram the activities required to produce a good, specify the time required to perform each activity in the process, and organize activities in the most efficient sequence. It also identifies a critical path: the sequence of activities that will entail the greatest amount of time.

Example

Our PERT chart shows how the activities involved in making a single bear are related. It indicates that the production process begins at the cutting station. Next, the fur that’s been cut for this particular bear moves first to the sewing and stuffing stations and then to the dressing station. At the same time that its fur is moving through this sequence of steps, the bear’s clothes are being cut and sewn and its T-shirt is being embroidered. Its backpack and tent accessories are also being made at the same time. Note that fur, clothes, and accessories all meet at the dressing station, where the bear is dressed and outfitted with its backpack. Finally, the finished bear is packaged and shipped to the customer’s house.

Our PERT chart shows how the activities involved in making a single bear are related. It indicates that the production process begins at the cutting station. Next, the fur that’s been cut for this particular bear moves first to the sewing and stuffing stations and then to the dressing station. At the same time that its fur is moving through this sequence of steps, the bear’s clothes are being cut and sewn and its T-shirt is being embroidered. Its backpack and tent accessories are also being made at the same time. Note that fur, clothes, and accessories all meet at the dressing station, where the bear is dressed and outfitted with its backpack. Finally, the finished bear is packaged and shipped to the customer’s house.

What was the critical path in this process? The path that took the longest amount of time was the sequence that included cutting, stuffing, dressing, packaging, and shipping—a sequence of steps taking sixty-five minutes. If you wanted to produce a bear more quickly, you’d have to save time on this path. Even if you saved the time on any of the other paths, you still wouldn’t finish the entire job any sooner: the finished clothes would just have to wait for the fur to be sewn and stuffed and moved to the dressing station. We can gain efficiency only by improving our performance on one or more of the activities along the critical path.

The Technology of Goods Production

PowerSki founder and CEO Bob Montgomery spent sixteen years designing the Jetboard and bringing it to production. At one point, in his efforts to get the design just right, he’d constructed thirty different prototypes. Montgomery thought that he could handle the designing of the engine without the aid of a computer. Before long, however, he realized that it was impossible to keep track of all the changes.

Computer-Aided Design

That’s when Montgomery turned to computer technology for help and began using a computer-aided design (CAD) software package to design not only the engine but also the board itself and many of its components. The CAD program enabled Montgomery and his team of engineers to test the product digitally and work out design problems before moving to the prototype stage.

The sophisticated CAD software allowed Montgomery and his team to put their design paper in a drawer and to start building both the board and the engine on a computer screen. By rotating the image on the screen, they could even view the design from every angle. Having used their CAD program to make more than four hundred design changes, they were ready to test the Jetboard in the water. During the tests, onboard sensors transmitted data to computers, allowing the team to make adjustments from the shore while the prototype was still in the water. Nowadays, PowerSki uses collaboration software to transmit design changes to the suppliers of the 340 components that make up the Jetboard. In fact, a majority of design work these days is done with the aid of computers, which add speed and precision to the process.

Computer Aided Manufacturing

For many companies, the next step is to link CAD to the manufacturing process. A computer-aided manufacturing (CAM) software system determines the steps needed to produce the component and instructs the machines that do the work. Because CAD and CAM programs can “talk” with each other, companies can build components that satisfy exactly the requirements set by the computer-generated model. CAD/CAM systems permit companies to design and manufacture goods faster, more efficiently, and at a lower cost, and they’re also effective in helping firms monitor and improve quality. CAD/CAM technology is used in many industries, including auto industry, electronics, and clothing. If you have ever seen how a 3-D printer works, you have a pretty good idea of how CAM works too.

Computer-Integrated Manufacturing

By automating and integrating all aspects of a company’s operations, computer-integrated manufacturing (CIM) systems have taken the integration of computer-aided design and manufacturing to a higher level–and are in fact revolutionizing the production process. CIM systems expand the capabilities of CAD/CAM. In addition to design and production application, they handle such functions as order entry, inventory control, warehousing, and shipping. In the manufacturing plant, the CIM system controls the functions of industrial robots–computer-controlled machines used to perform repetitive tasks that are also hard or dangerous for human workers to perform.

Producing for Quality

What do you do if your brand-new DVD player doesn’t work when you get it home? What if you were late for a test because it took you twenty minutes to get a burger and fries at a drive-through window? Like most people, you’d probably be more or less disgruntled. As a customer, you’re constantly assured that when products make it to market, they’re of the highest possible quality, and you tend to avoid brands that have failed to live up to your expectations or to producers’ claims.

But what is quality? According to the Society for Quality, the term quality refers to “the characteristics of a product or service that bear on its ability to satisfy stated or implied needs.” When you buy a DVD player, you expect it to play DVDs. When you go to a drive-through window, you expect to be served in a reasonable amount of time. If your expectations are not met, you’ll conclude that you’re the victim of poor-quality.

Quality Management

Total quality management (TQM), or quality assurance, includes all the steps that a company takes to ensure that its goods or services are of sufficiently high quality to meet customers’ needs. Generally speaking, a company adheres to TQM principles by focusing on three tasks:

- Customer satisfaction

- Employee involvement

- Continuous improvement

Let’s take a closer look at these three principles.

Customer Satisfaction

Companies that are committed to TQM understand that the purpose of a business is to generate a profit through customer satisfaction. Thus, they let their customers define quality by identifying desirable product features and then offering them. They encourage customers to tell them how to offer services that work the right way.

Armed with this knowledge, they take steps to make sure that providing quality is a factor in every facet of their operations—from design, to product planning and control, to sales and service. To get feedback on how well they’re doing, many companies routinely use surveys and other methods to monitor customer satisfaction. By tracking the results of feedback over time, they can see where they need to improve.

Employee Involvement

Successful TQM requires that everyone in the organization, not simply upper-level management, commits to satisfying the customer. When customers wait too long at a drive-through window, it’s the responsibility of a number of employees, not the manager alone. A defective DVD isn’t solely the responsibility of the manufacturer’s quality control department; it’s the responsibility of every employee involved in its design, production, and even shipping. To get everyone involved in the drive for quality assurance, managers must communicate the importance of quality to subordinates and motivate them to focus on customer satisfaction. Employees have to be properly trained not only to do their jobs but also to detect and correct quality problems.

In many companies, employees who perform similar jobs work as teams, sometimes called quality circles, to identify quality, efficiency, and other work-related problems, to propose solutions, and to work with management in implementing their recommendations.

Continuous improvement

An integral part of TQM is continuous improvement: the commitment to making constant improvements in the design, production, and delivery of goods and services.

Improvements can almost always be made to increase efficiency, reduce costs, and improve customer service and satisfaction. Everyone in the organization is constantly on the lookout for ways to do things better.

Statistical Process Control

Companies can use a variety of tools to identify areas for improvement. A common approach in manufacturing is called statistical process control. This technique monitors production quality by testing a sample of output to see whether goods in process are being made according to predetermined specifications. An example of a statistical process control method is Six Sigma. A Six-Sigma process is one in which 99.99966% of all opportunities to perform an operation are free of defects. This percentage equates to only 3.4 defects per million opportunities.

Key Takeaways

Assume for a moment that you work for Kellogg’s, the maker of Raisin Bran cereal. You know that it’s the company’s goal to pack two scoops of raisins in every box of cereal.

How can you test to determine whether this goal is being met? You could use a statistical process control method called a sampling distribution. On a periodic basis, you would take a box of cereal off the production line and measure the amount of raisins in the box. Then you’d record that amount on a control chart designed to compare actual quantities of raisins with the desired quantity (two scoops). If your chart shows that several samples in a row are low on raisins, you’d take corrective action.

Outsourcing

PowerSki’s Web site states that “PowerSki International has been founded to bring a new watercraft, the PowerSki Jetboard, and the engine technology behind it, to market.” That goal was reached in May 2003, when the firm emerged from a lengthy design period. Having already garnered praise for its innovative product, PowerSki was ready to begin mass-producing Jetboards. At this juncture, the management team made a strategic decision; rather than producing Jetboards in-house, they opted for outsourcing: having outside vendors manufacture the engines, fiberglass hulls, and associated parts. Assembly of the final product took place in a manufacturing facility owned by All American Power Sports in Moses Lake, Washington. This decision doesn’t mean that the company relinquished control over quality; in fact, every component that goes into the PowerSki Jetboard is manufactured to exact specifications set by PowerSki. One advantage of outsourcing its production function is that the management team can thereby devote its attention to refining its product design and designing future products.

Recapping

- Operations management oversees the process of transforming resources into goods and services.

- During production planning, managers determine how goods will be produced, where production will take place, and how manufacturing facilities will be laid out.

- In selecting the appropriate production process, managers consider three basic methods:

- make-to-order

- mass production

- mass customization

- In site selection for a company’s manufacturing operations, managers look for locations that minimize shipping costs, have an ample supply of skilled workers, provide a favourable community for workers and their families, offer resources at low cost, and have a favourable business climate.

- Commonly used inventory control methods include just-in-time (JIT) production, by which materials arrive just in time to enter the manufacturing process, and material requirements planning (MRP), a software tool to determine material needs.

- Gantt and PERT charts are two common tools used by operations managers.

- A Gantt chart helps operations managers determine the status of projects.

- PERT charts diagram the activities and time required and identify the critical path—the sequence of activities that will require the greatest amount of time.

- Service firms provide intangible products that are often customized to satisfy specific needs. Unlike manufactured goods, many services are bought and consumed at the same time.

- Estimating capacity needs for a service business is more difficult than for a manufacturer because service providers can’t store their services for later use.

- Many companies deliver quality goods and services by adhering to principles of total quality management (TQM).

- Outsourcing can save companies money by using lower cost, specialized labour, located domestically or abroad.

Attributions

Fundamentals of Business: Canadian Edition by Pamplin College of Business and Virgina Tech Libraries is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License, except where otherwise noted.

Operations Management by Saylor Academy licensed under CC BY 3.0 Unported

Introduction to Operations Management by Jérémie Gallien (MIT Open Courseware) licensed under CC BY NC SA 4.0

Fundamentals of Business by Stephen J. Stirpak licensed under CC BY 3.0

oversees the process of transforming resources into goods and services

for a company’s manufacturing operations, managers look for locations that minimize shipping costs, have an ample supply of skilled workers, provide a favorable community for workers and their families, offer resources at low cost, and have a favorable business climate.