1 Vertical Farming in Nunavut with IoT Automation

Note. Image generated using Generative AI (DALLE)

By: Ihab Azdou, Vazrik Mansoorian, Conor Murphy, Shahik Rakib & Matthew Wazen

September 6, 2023 / University of Ottawa – Telfer School of Business Management

The FinTech Explorer: A Comprehensive Guide

Most people know that food insecurity is common in third-world and underdeveloped countries, but what about in a place like Canada? Food insecurity is a significant issue in Nunavut, a Canadian territory located in the Arctic. With approximately 39,000 people, Nunavut faces extreme challenges when accessing fresh, affordable food. The high cost of living, extreme climate conditions, and lack of transportation infrastructure all contribute to the problem.

The average cost of groceries for one family per year in Nunavut is $23,904, and nearly 70% of the territory’s residents face food insecurity. This rate is eight times higher than the Canadian average. Additionally, the cost of food in Nunavut is almost three times higher than in other parts of Canada, according to the Nunavut Bureau of Statistics.

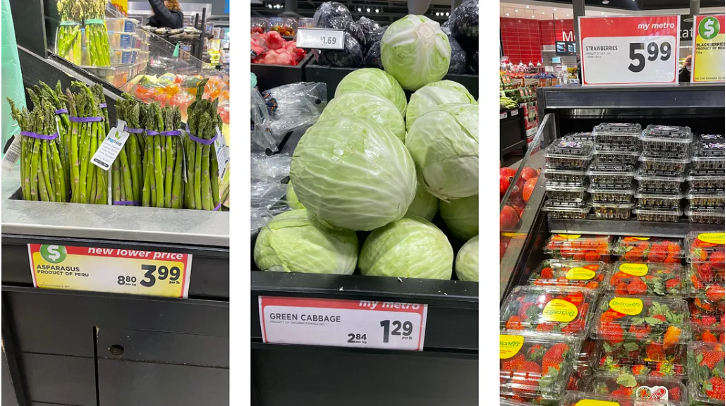

The examples of food prices in Nunavut are eye-opening and staggering. For instance, NorthMart, a grocery store in Iqaluit, charges $32.99 for a bundle of asparagus, $28.54 for a single cabbage, and $14.39 for strawberries. These prices are significantly higher than what one would expect to pay in other regions of Canada. The Nunavut Bureau of Statistics reports that almost everything in Nunavut’s supermarkets costs up to three times as much as the average Canadian store, making it difficult for residents to afford basic groceries. Other foods priced absurdly high in Nunavut include bottled water for $83.49, chicken burgers for $32.39,

Figure 1

Nunavut Family Protesting High Costs

Note. Retrieved from (https://medium.com/@peytonverhoeven/is-this-even-real-a-food-crisis-within-canada-265e6bad3b40)

Tropicana orange juice for $26.99, Munchies snack mix for $33.69, baby formula for $55.39, and a 12-pack of ginger ale for $82.49. The high cost of living in Nunavut and other remote parts of Canada can lead to food insecurity, where people struggle to access enough food for themselves and their families. To put it into perspective, here are the prices in a grocery store in Toronto, Ontario, taken at the same time the prices in Nunavut were recorded in Figure 2.

The climate in Nunavut is one of the significant factors contributing to the territory’s food insecurity. Winters in the capital city of Iqaluit have an average temperature of -27°C, making it almost impossible to grow crops outside like other provinces. Furthermore, most of Nunavut’s communities are remote, with no direct roads or rail lines. This leads to increased distances for shipping, higher shipping costs, and a reliance on unconventional importing methods, including planes and ships. Unfortunately, these methods are unreliable, with planes grounded for several weeks during winter storms and ships only arriving a few times a year.

However, a possible solution to Nunavut’s food insecurity problem. Indoor vertical farming has the potential to increase crop production, overcome land and climate limitations, and minimize the environmental impact of farming by decreasing delivery distances in the supply chain. The idea of vertical farming was first introduced by Gilbert Ellis Bailey in 1915, but a more modern approach was introduced by Professor Dickson Despommier in 1999. His vision was to grow crops in urban areas to minimize the distance and travel time of food.

Figure 2

Nunavut Grocery Prices

Note. Retrieved from (https://medium.com/@peytonverhoeven/is-this-even-real-a-food-crisis-within-canada-265e6bad3b40)

Figure 3

Toronto Grocery Prices

Note. Retrieved from (https://medium.com/@peytonverhoeven/is-this-even-real-a-food-crisis-within-canada-265e6bad3b40)

Vertical farming involves growing crops stacked in rows one on top of the other, using artificial light, temperature control, and nutrient-rich water instead of soil. This farming method allows year-round crop production in a controlled environment without pesticides or herbicides. Additionally, vertical farming can be done in small spaces, making it an ideal solution for Nunavut’s remote communities, where space is at a premium. Vertical farming could provide Nunavut with a sustainable source of fresh, affordable produce, helping to alleviate food insecurity in the territory.

Since most of the high cost of food in Nunavut is associated with transportation, the ideal solution would keep transportation costs low by growing the food within Nunavut, with vertical farming being that ideal solution.

In addition, past vertical farming initiatives within Nunavut have failed due to a lack of trained technicians. This labour issue can be solved by limiting the need for skilled human intervention or eliminating it through automation and community training.

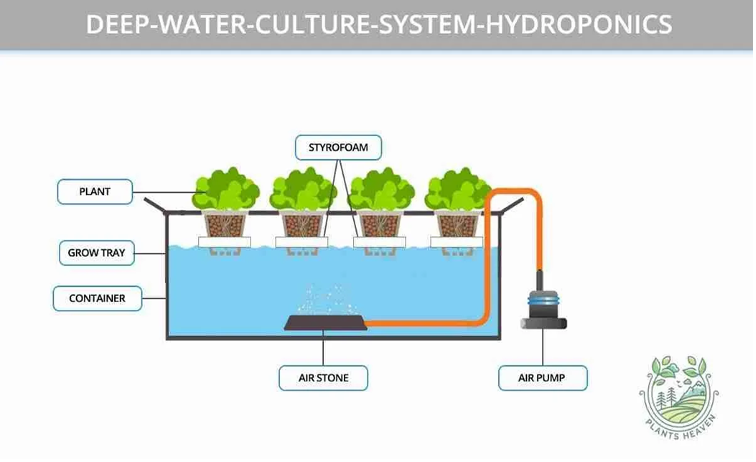

Deep Water Culture – Hydroponics System

As previously mentioned, hydroponics is a method of growing plants without soil, where the plants are instead produced in a nutrient-rich water solution. It is commonly used in a system where plants are grown in vertically stacked layers with a water circulation system that delivers the nutrient-rich water solution directly to the roots of the plants. The vertical arrangement of the system allows for more plants to be grown in a smaller area, maximizing space utilization. Additionally, the system can be controlled with precision, allowing for optimal conditions for plant growth, including temperature, humidity, and light levels. This results in faster growth rates and higher yields, making hydroponics a popular choice for vertical farming.

Deep water culture (DWC) hydroponics is one of the most straightforward hydroponics systems and is easy to operate. With a deep-water culture system, the plants are contained in a net pot suspended from the lid, and the roots are suspended in water with a nutrient-rich solution (Alpiné, 2023). It is used in vertical farm containers (Growcer, 2023) and has many benefits compared to traditional farming. It is also a better solution for Nunavut than other popular forms of vertical farming, like aquaponics (Epic Gardening, 2023). First, in DWC, there is greater control over nutrient balance: Growers have complete control over the nutrient balance of the solution, which allows for precise control over the growth of the plants.

On the other hand, in aquaponics, the nutrient balance is influenced by the fish waste and other aquatic animals in the system, which can be challenging to control. In addition, the nutrients in aquaponic systems may not be readily available to plants, requiring additional monitoring and supplementation. Second is a lower risk of disease: DWC systems are less likely to experience disease and pest issues as they do not use soil that can harbour pathogens and pests. Aquaponic systems have a greater risk of disease and pest problems due to the presence of fish and other aquatic animals if a disease or pest problem can quickly spread to the system’s plants and animals. Third is a lower cost and complexity: DWC systems are generally less expensive and easier to set up and maintain. Aquaponics requires additional equipment and resources, including fish tanks, filters, and aeration systems. In addition, aquaponic systems require more complex monitoring and management to maintain the system’s plant and animal components. Fifth is a higher crop yield: DWC hydroponic systems produce higher yields than traditional farming or aquaponic systems. This is due to the greater control over the nutrient balance and growth conditions in the system and the absence of potential disease and pest issues. Higher yields mean more food production per unit of space, which is especially important in space-limited areas where vertical farming is common. This also means that the grown plants can sustain more people and help lower the food cost in Nunavut. A sixth significant advantage is that these operations work better in cold temperatures, like in Nunavut, than traditional farming or aquaponic operations. Finally, these operations use less water to run, about 20 times less than a conventional farm. That means they can reduce the water cost in a place like Nunavut, where commodities such as water are costly.

Plants

Hydroponic farming is the process of growing plants in water instead of soil. (U.S. Department of Agriculture, n.d.). The advantage of this is that it can be used to grow crops faster. They also meet the needs of high nutrient-requiring plants (University of Minnesota, Small-scale hydroponics, 2023). This is advantageous in a vertical farming operation as certain natural elements, such as the sun, are missing. Using IoT technology, we can monitor the soil condition of the process and adjust it to meet the requirements of the plants. It can automatically sense when a particular crop is low on a required nutrient and supply it with that.

An advantage of hydroponic operations is that they lead to higher crop yields (National Park Service, 2021). This means that the plants being grown can sustain more people and can help to lower the cost of food in Nunavut. Another significant advantage is that these operations work better in cold temperatures than aquaponic operations (Hydroponic Way, 2022). They are not reliant on the quality of the soil in the area. Given that Nunavut is so cold, it makes sense. These operations also use less water to run, about 20 times less than a traditional farm (Upstart University, 2023). That means they can reduce the water cost in a place like Nunavut, where commodities such as water are costly (Fiddler, 2021).

Plant selection is important here not only for vertical farming but also for hydroponic operations. The two best types of crops are greens and herbs. Greens are vegetables such as kale, lettuce, and bok choy. Herbs are seasoning-type foods such as cilantro, mint, basil, and parsley (University of Minnesota, Small-scale hydroponics, 2023). Fortunately, these types of crops are suitable to be grown in a vertical farming operation and a hydroponic operation. These plants are straightforward to produce and require less than others, such as fruits and grains, requiring much higher light and heating inputs.

Other foods like tomatoes, peppers, and celery can still be grown in a hydroponic operation. As well as some fruits too. They are not the ideal plants to grow, but they can still be if required (University of Minnesota, Small-scale hydroponics, 2023). In this case, we are beginning with a new idea of vertical farming to reduce the cost of food. Therefore, at least in the beginning phase of this project, it may make sense to grow only the highest-yielding crops most suited to hydroponic environments and vertical farming. That keeps the original recommendation of plants like kale and spinach as the plants to use.

To look at IoT sensors, the best one we found for hydroponic operations was the SmartCultiva CT-700. This sensor is suited for hydroponic operations. It can detect temperature and humidity levels in the water solution, CO2 air levels, soil moisture levels and indoor and outdoor light sensitivity. This sensor can send real-time data on these parameters to any device through the cloud to any IoT device. It can also be used to turn on or turn off any devices connected to it, such as pH level sensors, water pumps, and LED lights for growing (SmartCultiva, 2023). In combination with other IoT devices, this sensor can prove very useful.

We plan to create an IoT parameter setting for spinach. Spinach requires a pH level between 6.5 and 8, ideal water solution temperatures are between 45- and 68 degrees Fahrenheit, and the ideal CO2 level is 1200PPM (University of Minnesota, 2023), (Pennsylvania State University, 2020), (Government of Manitoba, n.d.). We can use these specifications and create an IoT profile for spinach to ensure the plant grows optimally.

Automation

Lowering costs and decreasing human intervention within a greenhouse will require automation. Automation has become a big part of many industries when it comes to cutting costs, whether it be a manufacturing firm using automation to cut down on labour costs (Hitomi, 1994) or a law firm using automation to lower their process costs, (Walshe, 1982), this technology can influence the bottom line and lower prices for the end-consumer.

When looking at automation for a greenhouse in Nunavut, several criteria must be considered before a specific technology solution is chosen:

Table 1

Greenhouse Automation Criteria with Reasoning

| Criteria | Reasoning |

| Low-Cost | Greenhouse automation aims to lower costs and pass those savings to the consumer. |

| Automates Greenhouse-Specific Functions | Decrease the need for human intervention/human labour. |

| Data Collection | Data needs to be collected to determine the effectiveness of greenhouse automation and apply predictive analysis. |

| Resilient to Nunavut’s Environment | Automation infrastructure needs to be able to withstand low northern temperatures. |

LoRaWAN, Long-Range Wide-Area-Networks, was chosen as the technology solution for the vertical-farming initiative since it best fits the above criteria. LoRaWAN is a specific Low Power Wide Area Networking (LPWAN) communications protocol (Haxhibeqiri et al, 2018). This communications protocol was designed to connect battery-operated devices to the internet wirelessly. This protocol was built to be used with Internet of Things (IoT) devices, and as such, satisfies critical requirements for IoT devices:

Table 2

IoT Requirements with Reasoning

| Requirements | Reasoning |

| Bi-directional communication | Data and requests need to be transmitted between two endpoints, the IoT device and the IoT operator. |

| End-to-end security | The data needs to be secure when in flight between the two endpoints. |

| Mobility | Some IoT sensors operate as trackers or collect data while attached to moving platforms. |

| Localization Services | Some IoT sensors need to be located for tracking or distribution purposes; this is done through triangulation and trilateration. |

LoRaWAN is an open-source protocol, meaning anyone with the technical know-how can create their own LoRaWAN network to communicate with IoT devices. Although most businesses and individuals need the technological capacity to develop their own LoRaWAN network, several enterprise-level solutions are available to consumers, ranging from hosted LoRaWAN networks (The Things Network, 2023) to fully integrated plug-and-play ecosystems (SmartBee, 2023). We have identified three LoRaWAN solutions, which range from DIY to fully hosted, in Table 3.

Using a hosted solution, like the one provided by TTN, is the best option for a niche farming use case. Our chosen crops, combined with environmental conditions, make a situation where a plug-and-play system, such as the one provided by Smart Bee, would not be sufficient. Additionally, a DIY solution would not be preferable since deploying and maintaining infrastructure within Nunavut is already tricky. Using a hosted solution instead would allow for part of the infrastructure to be located outside of Nunavut on cloud-based servers.

Additionally, a hosted solution instead of a plug-and-play solution would allow integration with any IoT device communicating using the LoRaWAN protocol. Using a solution such as Smart Bee’s would limit the operator to the Smart Bee ecosystem of IoT devices.

Table 3

Solution Types, Vendors, and Solution Details

| Solution Type | Developer/Vendor | Solution Details |

| DIY | Internal Development | Deploying firm develops their own LoRaWAN network based on their specific needs. |

| Hosted Solution | The Things Network (TTN) | Deploying firm develops its own LoRaWAN network using TTN’s servers and tools. |

| Ready-to-Deploy | SmartBee Controllers | Deploying firm purchases a product bundle of their choice, and the network is ready to be deployed upon product delivery. |

IoT Devices

IoT, or the “Internet of Things,” is a global network of individual hardware that allows for communication between devices and humans through the Internet. IoT devices are used in numerous industries and residential buildings to monitor and detect activity and collect and transmit data. This is because they also have power-saving capabilities beyond their general uses. These devices/sensors are mainly powered by batteries or energy from limited, low-cost sources. Portable and simple to install, they are an economical technology appropriate for a tight budget and little technical knowledge. Management of devices and data is also made efficient by programs. One of them is Digi Remote Manager, an interface that allows for long-range management of multiple IoT devices and data around the globe.

An IoT valuable vertical or outdoor farming device is the WSS-07 PAR by Dragino. It senses critical photosynthetically active radiation (PAR), which is solar radiation falling within the wavelength range of 400 to 700 nanometers. Naturally, sunlight varies between seasons and geography, but artificial light can facilitate photosynthesis if it falls within this spectrum. The WSS-07 requires an input of 5-24V, consumes 3mA at 12V and operates between the temperatures of -30 to 75 Celsius, making it reliable in vertical farming and slightly warmer outdoor temperatures in Nunavut. Priced at $229 per device, this technology can measure the light wavelengths in an enclosed greenhouse without requiring many devices.

Figure 4

Photosynthetic Active Radiation Sensor

Note. Retrieved from Choovio, 2023 (https://www.choovio.com/product/wss-07-par-photosynthetically-active-available-radiation/)

Another factor critical to farming is soil quality. Dragino’s LoRaWAN “LSPH01” is a pH and temperature sensor with low power consumption and a long battery life of 10 years (8500mAh battery). Necessary for its function in wet soil, the device also has IP66 rated enclosure to protect it from water damage. The LoRa technology in LSPH01 allows for remote long-range data transfer. A complimentary device to the LSPH01, the LSE01 product, with the same battery and low consumption capabilities as its counterpart, measures soil moisture and electrical conductivity. In combination, the two devices can bring to the attention of farmers if pH or water levels need to be tampered with to ensure ideal farming conditions. This can make irrigation or water-recycling practices much more accurate and efficient for the well-being of plants. The four factors these two devices monitor are vital in the most fundamental, traditional farming, and even more so in automated, greenhouse, vertical farming processes. Each LSPH01 and LSE01 sells for $128.94, for a combined price of $257.88, making them a fixed and relatively inexpensive investment for the benefits they provide.

IoT devices can facilitate greater sustainability and yield through constant monitoring and information in the farming space. Specific data allow for more informed predictions, resource management decisions, and livestock health. Whether managing risk or costs, IoT devices allow farmers to utilize smart agriculture for increased efficiency.

We also believe it is essential to supply Nunavut with locally grown crops to reduce the cost of food in the territory. Right now, it is simply too expensive. So, a local greenhouse operation could reduce the cost. One way to start this off is with our crop recommendation of spinach. Spinach is one of the world’s healthiest vegetables and most efficient to grow in a hydroponic operation.

Solutions:

- IoT can reduce the need for human intervention in a greenhouse

- Locally produced from a greenhouse, lower transportation costs

- IoT sensors do not put additional strain on a greenhouse’s energy requirements

- A tailored vertical farming solution: a solution to food insecurity (go into detail – hydroponic system, plants, HVAC/electricity, IoT devices, LoRaWAN)

Analysis

Deep Water Culture – Hydroponics System

Since we now understand the benefits of a hydroponic system, here is a step-by-step explanation of how it works (Epic Gardening, 2023). Every DWC system has the following essential components: A water container or reservoir, an air pump, hydroponics nutrients, an Air hose and air stones for bubble generation, growing media to support the plant in the basket, grow nets or baskets to contain the plants, and equipment to monitor the pH and E.C. of the nutrient solution (Plants Heaven, 2023).

Figure 5

Deep water culture system of hydroponic farms

Note. Retrieved from (https://plantsheaven.com/deep-water-culture-advantages-and-disadvantages/)

We must choose a growing container to grow the plants to build an aquaponics system. It can be a simple plastic bucket, a PVC pipe, or a more complex hydroponic system designed for specific types of plants. Then, we need to add a growing medium: hydroponic plants need something to hold onto and support their roots since they are not growing in soil. Common growing media include perlite, vermiculite, coconut coir, rockwool, or clay pebbles. The growing medium should be clean, pH-neutral, and contaminant-free. After adding a growing medium, we set up the nutrient solution: a nutrient-rich solution is mixed with water and added to the growing container. The nutrient solution comprises the essential macronutrients and micronutrients that plants need to grow, such as nitrogen, phosphorus, potassium, calcium, magnesium, and trace elements.

To ensure optimal plant growth, the nutrient solution should be pH balanced, with a pH range between 5.5 and 6.5, to ensure optimal plant growth. To determine when to add nutrients, growers regularly monitor the nutrient solution’s pH and electrical conductivity (E.C.) levels. If the nutrient solution’s pH or E.C. levels fall outside the desired range, the grower may need to adjust the nutrient levels by adding more nutrients or changing the water to maintain optimal plant growth. After adding the nutrients, the grower plants the seedlings. The seedlings can be planted once the growing medium and nutrient solution are set up. The roots of the seedlings are placed in the growing medium, which holds them in place and provides support. The nutrient-rich solution then circulates the roots, giving them the necessary nutrients for growth. The system also needs to be maintained to ensure optimal plant growth. This includes monitoring the pH and nutrient levels of the solution, checking the water levels in the reservoir, and maintaining proper air circulation and temperature control. Some systems also require periodic cleaning to prevent algae growth or other issues.

Moreover, since water is recycled through a closed-loop system, the same water is reused multiple times. As the water circulates through the system, it becomes depleted of nutrients and can accumulate unwanted substances like salts or bacteria. To ensure the water remains clean and healthy for the plants, the system employs a series of filtration methods to remove any impurities. By recycling the same water through the system and utilizing filtration and sterilization methods, hydroponic systems minimize water waste and maintain a healthy growing environment for the plants.

A hydroponic operation is different from a traditional farm. New techniques are involved with the process that must be taught to the farmers there. To avoid needing technicians, simple training can be done to teach the locals how to maintain their vertical farms. The Arctic Research Foundation has found a way to teach a community in Nunavut to inspire self-sufficiency, interest, and skill development in horticulture. They have received nothing but positive responses from the locals, and several other communities have also expressed interest (Greenhouse Canada, 2020). Another organization that offers an education program to tackle the issues of food insecurity in Nunavut is Green Iglu. After building the vertical farms and providing the tools and infrastructure needed, Green Iglu does community training that comprises modules of 13 units ranging from basic Plant Biology to Advanced Hydroponics. Participants get plenty of hands-on learning and more traditional lecture-type education offered in grade 4 English reading level, suitable for all age groups and literacy levels (Green Iglu, 2023). This trains the community to be self-reliant and reduces the need for technicians to be present on the floor. We can thus recommend a government incentive program to fund and train farmers undertaking indoor vertical farming operations.

IoT Devices

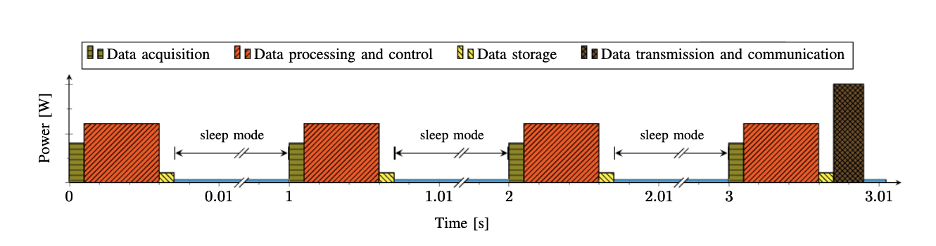

The power-saving capabilities of an IoT sensor are intentional. Within a sensor, data goes through 4 stages: acquisition, process and control, storage, and transmission (communication). IoT devices also have numerous power modes such as active, idle, off and sleep, allowing for more cost-efficient energy use and avoiding waste (Henkel, Jörg & Pagani, Santiago & Amrouch, Hussam & Bauer, Lars & Samie; Farzad, 2017).

Figure 6

Abstract examples of the operation of an IoT device concerning time, including the different stages of the process, their standard sequence, and some possible power consumption values. The sensor is updated with a period of 1 s.

Note. Retrieved from “Ultra-Low Power and Dependability for IoT Devices Special session paper,” by Henkel, Jörg & Pagani, Santiago & Amrouch, Hussam & Bauer, Lars & Samie, Farzad, 2017. Researchgate.

Automation

Additionally, the network requirements of a vertical-farming initiative warrant using a hosted LoRaWAN solution, such as the solution provided by The Things Network (The Things Network, 2023). TTN allows individuals and firms to use any device within the LoRaWAN compatible stack since they work with deploying firms down at the LoRaWAN protocol level. The deploying firm is not entirely reliant on its internal developers, but at the same time, they are not restricted to whatever product suite is offered by its product vendor. Greenhouse-specific functions, such as humidity detection, can be built into the network due to the open-source nature of LoRaWAN. Furthermore, any sensor within the stack can be utilized, allowing the deploying firm to pick their required IoT sensors after considering their given use case. Another advantage to using a hosted network is the flexibility provided regarding data analysis. On an open-source and hosted solution, deploying firms can use an application of their choice to conduct data analytics. Deploying firms may want to conduct prescriptive analysis alongside using the data as automation triggers. As well, plant selection is essential. During the initial implementation phase of this project, it is better to focus on one high-quality vegetable that can sustain its local community. Spinach is that vegetable. Adding higher quality food to the grocery supply can help improve that community’s quality of life.

Nunavut’s Optimal Solution for Combatting Food Insecurity

Hydroponics is at the core of vertical farming operations. We found that DWC hydroponics is the most suitable for Nunavut, which faces significant challenges in terms of climate and limited access to fresh produce. DWC systems are simple to operate and highly efficient in using water and nutrients, making them well-suited for remote regions with limited resources. They can also be easily scaled to fit the needs of local communities and provide a sustainable source of fresh produce year-round. Community engagement and education to complement some level of automation will be critical for ensuring this hydroponics project’s success and long-term sustainability. Beyond that, given that this project is vital, we recommend spinach as the super vegetable to help feed the Nunavut community. It is high in nutritional value and easy to grow.

Due to their simplicity, cost, power-saving capabilities, and data accuracy and automation benefits, IoT devices should be used in vertical farming in Nunavut. WSS-07 PAR, LSPH01 and LSE01 by Dragino monitor five critical factors in agriculture. By ensuring ideal conditions for livestock health, such as photosynthetically active radiation in light, moisture, pH, electrical conductivity and soil temperature, these three IoT devices are the best to aid farming in Nunavut. With transportation and installation costs being minimized due to their size, the three Dragino products should be used for monitoring soil and PAR data to lower the reliance on technicians and give more consistent data to farmers.

Additionally, since we recommend using IoT devices, we also recommend a LoRaWAN technology solution to go along with it. We recommend deploying firms using a hosted LoRaWAN solution from a provider like The Things Network. We recommend that deploying firms refrain from completely DIY solutions and centralized product suites, as the former offers too much flexibility while the latter offers none.

These processes and decisions discussed, if implemented, can provide legitimate and efficient solutions to the farming and food insecurity problems of Nunavut.

References

Altiné. Here are Deep Water Culture Advantages and Disadvantages (And how to fix them). Plants Heaven. Retrieved March 14, 2023, from https://plantsheaven.com/deep-water-culture-advantages-and-disadvantages/

CHOOVIO IoT Solutions. (2023, February 13) Retrieved February 25, 2023, from https://www.choovio.com/lorawan-in-smart-agriculture-and-farming/

Epic Gardening. Hydroponic Systems. Epic Gardening. Retrieved April 20, 2023, from https://www.epicgardening.com/hydroponic-systems/

Fiddler, W. (October 14, 2021). Iqaluit residents collect river water, city fills up tanks after gasoline suspected in tap water. Globe and Mail. Retrieved from: https://www.theglobeandmail.com/canada/article-iqaluit-residents-collect-river-water-city-fills-up-tanks-after/#Bottled%20water%20normally%20sells%20at,a%2024%2Dpack%20is%20%2427.99

Fondriest Staff. (2022, August 8). What is photosynthetically active radiation? Environmental Monitor. Retrieved March 21, 2023, from https://www.fondriest.com/news/Photosyntheticradiation.htm#Photosynthetically%20Active%20Radiation%20(PAR)%20is,the%20summer%20at%20mid%2Dday

Government of Manitoba. (n.d.). Agriculture. Government of Manitoba. Retrieved from:

https://www.gov.mb.ca/agriculture/crops/crop-management/co2-supplement.html#The%20level%20of%201000%20PPM,photosynthesis%20at%20the%20maximum%20rate

Green Iglu. The Education Programming. Green Iglu. Retrieved April 25, 2023, from https://www.greeniglu.com/education-programming

Greta Chiu (2020, June 8). A haven for northern growth. Greenhouse Canada. Retrieved March 14, 2023, from https://www.greenhousecanada.com/a-haven-for-northern-growth/

Growcer. Step Into a Growcer Farm. Growcer. Retrieved April 20, 2023, from https://www.thegrowcer.ca/virtual-farm-tour

Haxhibeqiri, Jetmir, et al. “A Survey of Lorawan for IOT: From Technology to Application.” Sensors, vol. 18, no. 11, 2018, p. 3995., https://doi.org/10.3390/s18113995.

Henkel, Jörg & Pagani, Santiago & Amrouch, Hussam & Bauer, Lars & Samie, Farzad. (2017, March). Ultra-Low Power and Dependability for IoT Devices (Special session paper). Retrieved March 14, 2023, from https://www.researchgate.net/publication/312214220_Ultra-Low_Power_and_Dependability_for_IoT_Devices_Special_session_paper

Hitomi, Katsundo. “Automation — Its Concept and a Short History.” Technovation, vol. 14, no. 2, 1994, pp. 121–128., https://doi.org/10.1016/0166-4972(94)90101-5.

Hydroponic Way. (Aug. 19, 2022). Successful Hydroponics in Any Climate. Hydroponic Way. Retrieved from: https://hydroponicway.com/hydroponics-in-climates#Some%20good%20examples%20of%20hydroponic%20systems%20for%20polar%20climates%20include,and%20can%20tolerate%20freezing%20temperatures.Lorawan in smart agriculture and farming.

National Park Service, U.S. Department of Interior. (2021) Hydroponics: A Better Way to Grow Food. National Park Service, U.S. Department of Interior. Retrieved from: https://www.nps.gov/articles/hydroponics.htm

Oklahoma State University Cooperative Extension Service. (2017). Hydroponics. Retrieved April 26, 2023, from https://extension.okstate.edu/fact-sheets/hydroponics.html

Pennsylvania State University. (n.d.). Growing Spinach, A Cool-Season Vegetable. Pennsylvania State University. Retrieved from: https://extension.psu.edu/growing-spinach-a-cool-season-vegetable#One%20key%20to%20successfully%20growing,of%2045%E2%81%B0%20F%20to%2068%E2%81%B0F

SmartBee™ Controllers. (2022). The best automated grow systems for home. Retrieved from https://smartbeecontrollers.com/

Smartcultiva. (2018). Smart Agriculture IOT Sensors to Monitor Hydroponic / Aquaponics and Soil greenhouse indoor Farming. Smart Cultive. Retrieved from:

https://www.smartcultiva.com/

The Things Network. (2023). The Things Network. Retrieved from https://www.thethingsnetwork.org/

University of Minnesota. (2023). Growing Spinach and Swiss chard in home gardens. University of Minnesota. Retrieved from: https://extension.umn.edu/vegetables/growing-spinach-and-swiss-chard#Spinach%20will%20do%20best%20in,according%20to%20soil%20test%20recommendations

University of Minnesota. (2023). Small-scale hydroponics. University of Minnesota. Retrieved from: https://extension.umn.edu/how/small-scale-hydroponics#plant-selection-2645210

Upstart University. (2023). How efficient is water use in hydroponics and aquaponics? Upstart University. Retrieved from: http://help.upstartuniversity.net/en/articles/941911-how-efficient-is-water-use-in-hydroponics-aquaponics

U.S. Department of Agriculture. (n.d.). Hydroponics. U.S. Department of Agriculture. Retrieved from: https://www.nal.usda.gov/farms-and-agricultural-production-systems/hydroponics

Verhoeven, P. (2021, May 25). Is This Even Real? A Food Crisis Within Canada. Medium. Retrieved March 14, 2023, from https://medium.com/@peytonverhoeven/is-this-even-real-a-food-crisis-within-canada-265e6bad3b40

Walshe, W. A. (1982). Law office automation gains momentum. American Bar Association Journal, 68, 292.