8.2 – Relays and Solenoids

Electromagnetic Relays

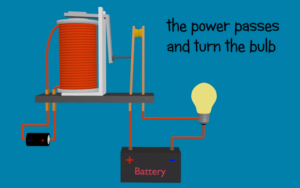

The most common and widely used type of electrical relay is the electromechanical relay or EMR

The most fundamental control of any equipment is the ability to turn it “ON” and “OFF”. The easiest way to do this is using switches to interrupt the electrical supply. Although switches can be used to control something, they have their disadvantages. The biggest one is that they have to be manually (physically) turned “ON” or “OFF”. Also, they are relatively large, slow and only switch small electrical currents.

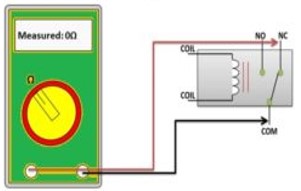

How testing a Relay?

Common failures of solenoids:

- Life cycle wear

- Environmental factors

- Power supply problems

The troubleshooting process for relays and solenoids is very similar to that of transformers.

- Check to ensure that there is voltage to the coil.

- Examine the insulation of the wires that produce the magnetic force. Never attempt to rewind the coil.

- Test the continuity of the solder joints at all terminals.

- Always ensure that plug-in relays are properly seated into the socket.

- Always clean the area around the relay or solenoid to eliminate future problems created by debris preventing full contact.

Attributions

- Figure 8.2.1: Omron G2R-2-24V Relay by Retired electrician, courtesy of Wikimedia commons and licensed under CC0 1.0

- Figure 8.2.2

- Figure 8.3.3: How to Test a Relay Using Multimeter by Soldering Mind