3 Emergency Procedures

All employers are obligated to ensure staff are trained in workplace emergency procedures. This may include what to do in case of a fire, earthquake, or other emergency; identifying locations of emergency exits; and processes to follow to evacuate the building in the case of an emergency. These procedures are site specific and should be a part of the training for all new employees. In addition, regular drills or reviews of procedures are important to ensure that if an actual emergency occurs, everyone is able to react accordingly and safely.

Orientation to any new job site, even if temporary, should always include the following information:

- Location of emergency exits

- Location of first aid supplies or the procedures to call for an attendant

- Location of fire extinguishers

- Evacuation procedures and muster stations

- Any hazards present on the site

First Aid Procedures

Providing access to first aid supplies or attendants is a requirement of employers under the OHS Regulation, but the required vary according to the size of the employer and many other factors. For example, in some cases it is required that a designated first aid attendant be on duty, while in others it is enough to provide a first aid kit stocked with a prescribed list of supplies. Many industrial settings and B.C. training institutions are equipped with a first aid station with a trained attendant. The person who staffs that station is able to perform a wide variety of services from bandaging minor cuts to stopping major bleeding and splinting broken bones.

All workers should know where the first aid station is, who staffs it, and what services are available. If you sustain an injury, no matter how minor, ensure that the incident is reported in the first aid station log. Minor irritations often develop into major problems, so report all injuries promptly.

Emergency Wash Station or Shower Locations

There may be times when you are working with acids or hazardous substances such as cleaning solutions which may burn your flesh or splash into your eyes. If you accidentally splash or spill a corrosive substance on your skin, you will want to wash the affected area very quickly with large amounts of water to dilute the acid and minimize burning. It is therefore necessary that you be aware of the location of your emergency eyewash stations, sinks, or showers throughout your work site.

Fire Safety Procedures and Regulations

Components that produce fire

Before a fire can occur, these three components must be present:

- Fuel (a combustible material such as wood, gasoline, paper, or cloth)

- Heat (sufficient to raise the fuel to its ignition temperature)

- Oxygen, usually in the form of air (to sustain combustion)

When these three components combine, as shown in the fire triangle (Figure 14), the result is rapid combustion (fire). Keeping these three components separated will prevent a fire from occurring. An existing fire can be extinguished by removing any one of the three components:

- Remove the fuel (combustible material) from the vicinity of the fire. For example, if you shut off the valve of a gas main, the result will be starvation.

- Remove the heat. For example, by applying water, the result will be cooling.

- Remove the oxygen. For example, if you cover the fire with a lid, a wet blanket, or some sand, or you use a carbon dioxide, foam, or dry chemical extinguisher, the result is smothering.

Remember, keeping these three components separated will prevent a fire from occurring. Likewise, an existing fire can be extinguished by removing any one of the three components.

Combustion speed

Fire, or combustion, is a form of oxidation (the union of a substance with oxygen). During the process of oxidation, energy is released in the form of heat — sometimes accompanied by light. Oxidation takes place at varying rates of speed. Table 1 shows examples of oxidation occurring at differing rates of speed.

| Speed | Example |

| Very slow | The rusting of iron |

| Slow | The spontaneous heating of materials such as oil soaked rags |

| Fast | The burning of paper or wood |

| Extremely fast | The exploding of gunpowder upon ignition |

Table 1. Combustion speeds

First aid firefighting

First aid firefighting is best described as extinguishing a fire in its initial stages (before the fire can become too large) by using whatever is readily at hand. First aid extinguishers are designed to deal with fires in their infancy. These traditional fire extinguishers are still required on all work sites, even in areas protected by sprinkler systems.

Classes of fires

Fires are divided into five main classes: A, B, C, D, and K. The classification of a fire dictates the type of extinguisher required.

The symbols shown in Table 2 may be the only indication you have of the best use for a fire extinguisher. Please make note of the class letter and symbols for future reference.

Table 2. Classes of fires. (Fire class letter symbols by Andros 1337 is under CC BY SA 3.0. Pictograms by Renata3 is under Public Domain.)

Types of fire extinguishers

All businesses must have portable fire extinguishers. These come in many sizes and colours and have several markings on them. They may be divided into several types:

- Water extinguishers

- Dry chemical extinguishers

- Wet chemical extinguishers

- CO2 extinguishers

Although most of these extinguishers can be used on more than one class of fire, none can be successfully used for all types of fire situations.

Water-based extinguishers are to be used on Class A fires and may be either the pressurized or pump type. Plain water extinguishers are rarely found in the kitchen.

Dry chemical extinguishers are designed for Class B and C fires or Class A, B, and C fires, depending on the type of agent contained in the cylinder. Three of the most commonly used dry chemicals are:

- Triplex dry chemical, a multipurpose dry chemical agent effective in extinguishing Class, A, B, and C fires, is generally considered the best all-round fire extinguisher.

- Quick-aid dry chemical, a specially treated sodium bicarbonate dry chemical agent that is moisture-resistant and free-flowing, is effective and approved for use on Class B and C fires and offers the lowest cost per kilo of the three dry chemical agents.

- Purple K dry chemical, a specially treated potassium bicarbonate dry chemical agent, provides effective protection against Class B and C fires and is approximately twice as effective as the standard sodium bicarbonate dry chemical.

You can use dry chemical extinguishers to put out Class D fires. However, the type of extinguisher depends on the type of metal that is burning. If you are working with a particular combustible metal, ask your instructor for information about the most effective extinguisher.

Wet chemical fire extinguishers became mandatory after discovering that modern shortenings burn at a higher temperature than other frying oils making the automatic fire suppression systems unable to extinguish larger fryer fires. The extinguishers for Class K fires are grey in colour and contain a potassium acetate based, low PH agent. The Class K extinguisher is also the ideal choice for use on all cooking appliances including solid fuel charbroilers. The agent discharges as a fine mist that helps prevent grease splash and fire reflash while cooling the appliance.

Carbon dioxide (CO2) extinguishers should be used on Class B and C fires. A CO2 extinguisher is recognized by its fibre horn. It is less effective than dry chemical extinguishers but has the advantage of not leaving a residue that must be cleaned.

It is important that you know the location of and how to operate each extinguisher in your workplace. Because each manufacturer uses a slightly different operating procedure, the best thing you can do is to look carefully at the markings and instructions on the extinguisher. They will tell you how to use the extinguisher and where it is most effective.

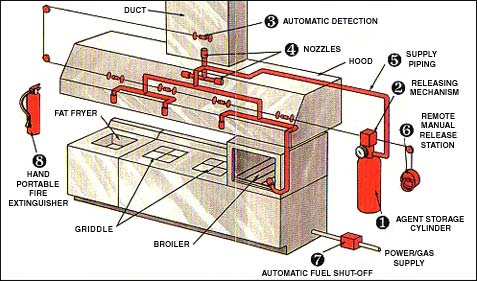

Fire extinguishing systems for commercial cooking equipment

Commercial cooking equipment that produces grease-laden vapours is considered to be a special fire hazard. To reduce the chance of fire, grease-extracting ventilation systems are equipped with automatic fire extinguishing equipment. A typical automatic extinguishing system fitted over a charbroiler and deep fat fryer is shown in Figure 15.

This automatic system may use a dry chemical, a wet chemical, carbon dioxide, or water from sprinklers as an extinguishing agent.

A large number of the fires in ventilating equipment are caused by the buildup of grease due to poor housekeeping. Keep the hood and other equipment as clean as possible. Servicing should include a thorough inspection of all the components and a test activation of the system without the extinguishing agent. Servicing should include the following:

- Storage containers for stored-pressure dry chemical systems must be weighed and checked for pressure. The expellant gas cartridge of non-stored pressure systems should be checked for pressure or weight and the dry chemical examined for moisture.

- Nozzles and lines should be cleaned and the protective covers checked. Sprinkler heads and spray nozzles must be replaced annually.

- The hood, extraction equipment, and ducting should be cleaned and maintained on a regular basis.

Fire Prevention Measures

As noted above, fire is only possible where there is a supply of combustible materials, oxygen, and heat. However, lack of caution, equipment failure, or simple human error can cause ignition. Here are some fire safety precautions for working near, handling, or storing flammable materials.

Flammable liquids and related equipment

The nature of flammable liquids makes them very vulnerable to ignition. Consequently, the following storage precautions are necessary:

- All containers of flammable liquids must be of an approved type and clearly marked.

- All containers must have secure capping devices.

- Open flames or lit cigarettes must be prohibited within or near any liquid-gas storage area.

- Where drums are used as containers, they must have taps and a drip tray.

- Transportation must only take place while containers are sealed.

- All empty containers must be stored on end.

- Spills must be cleaned up or covered with sand.

Any equipment that requires a flammable liquid needs the same basic precautionary measures as stored liquids. All tank or equipment leaks must be reported and then repaired immediately.

All waste liquids that are flammable must be placed in approved containers for disposal and taken to the appropriate location for disposal according to municipal waste disposal regulations.

Paper and wood products

Dry paper and wood are susceptible to ignition quite easily. When damp or wet, they do not ignite quickly. Keep all paper and wood products away from open flames such as burners and pilot lights.

Oily cloths

All oily cloths must be placed in metal bins with sealed lids and sent to be laundered professionally.

Oils and fats

All oils and fats have a predetermined flash point at which they will ignite. This is considerably higher than the smoke point where the oil gives off large amounts of smoke, which is a good indicator that the heat should be removed or turned down. For safety considerations, allow oil to cool down before removing or recycling.

Garbage and clutter

Garbage and clutter present a problem in fire prevention for two reasons. Garbage may contain substances that are toxic when burned, and clutter in high traffic areas may present an obstruction for fire fighters or for those trying to evacuate a building. Always ensure that exit corridors are kept clear and that garbage is disposed of regularly.

Fire Prevention Rules for the Kitchen

The following are important rules to remember while you work in the food preparation and storage areas of a kitchen:

- Keep a supply of salt or baking soda handy to extinguish small fires on range tops or under charbroilers.

- Don’t ever put water onto a fire containing oil or grease.

- Keep hoods and other equipment free from grease buildup.

- Do not leave hot fat unattended on the range.

- If a fire alarm sounds, turn off all gas and electrical appliances before leaving the building.

- Remove all rubbish regularly.

- Store all dry goods neatly, and make sure they do not impede traffic flow in the area.

- Do not leave grease rags around the kitchen, particularly near stoves.

- Keep fire doors closed at all times

- Keep fire stairs and fire exits clear of any obstruction.

- Keep all fire exits clearly marked and lighted.

- Check all automatic fire extinguishing systems on a regular basis. Remember, full servicing is required every six months.