5.1: Globalization of Procurement, Sourcing, and Outsourcing

Globalization gives tremendous opportunities for companies to increase competitive advantage by using international sourcing or acquiring cutting-edge technologies. The process of purchasing services or goods worldwide to bid on contracts is called international procurement. The process is increasingly essential for organizations globally. It helps organizations enhance their competitive position, meet customer expectations, improve profits, and add value by finding suppliers who meet the organization’s strategy.

All businesses have to be competitive to succeed in the market. The procurement of goods and services plays a vital role in the following areas:

- economic growth

- fulfilling stakeholder needs

- uniting suppliers

- identifying and organizing sources

- managing the supply chain

- renewing contracts

- specifying requirements

- evaluating available options

Procuring goods or services can be done across continents or countries provided specific international and national requirements and trade regulations are followed.

Public Procurement Playbook

Watch this video to get a basic understanding of Procurement as an essential business function.

Source: Procurious HQ. (2014, May 22). Introduction to Procurement—Module 1: What is Procurement? (Part 1). [Video]. YouTube. https://youtu.be/wPR_KoSSofA?si=GAKaQdgO17cNISzn

Procurement and its Value in the Global Value Chain

What Is Procurement?

Mangan and Lalwani (2016) share the following insights about procurement:

- “Procurement includes sourcing and purchasing and covers all of the activities from identifying potential suppliers through top delivery from supplier to the customer.” (p. 379).

- “Procurement is about specifying requirements, identifying sources, evaluating options, and acquiring resources that are fit for purpose, cost-effective and sustainable.” (p. 144).

- “Managing risks and value on behalf of the company is the role of procurement.” (p. 148).

Globalization and trade liberalization have provided tremendous opportunities for companies to increase competitive advantage by using international sourcing and have been a significant stimulus to economic growth throughout the world.

International procurement is the process of purchasing services or goods worldwide by bidding on contracts. The process is increasingly essential for organizations globally. It helps organizations enhance their competitive position, meet customer expectations, improve profits, and add value by finding suppliers who share the organization’s viewpoints and overall business strategy.

International procurement creates efficiencies in supply chain management. It makes it possible for smaller companies to obtain a wider selection of goods and services at more competitive prices from all over the world. (Scully & Fawcett, 1994). However, specific knowledge and special skills are required to succeed in international procurement.

The Procurement Process and its Steps

Before delving deeper into the procurement steps, let’s look at the types of procurement processes.

Public Procurement Playbook

Watch this video on the different types of procurement processes used by Irish public bodies and how businesses can access these opportunities.

Source: Office of Government Procurement Ireland. (2018, January 11). Types of Procurement Process. [Video]. YouTube. https://youtu.be/_490ZEaYdwA?si=D2Uh7f1kQ2E3qiHM.

Here is a clear explanation of the procurement process in services such as project management from the chapter on procurement management in Adrienne Watt’s: Project Management (Watt, 2014).

Procurement management follows a logical order. First, you plan what you need to contract; then you plan how you’ll do it. Next, you send out your contract requirements to sellers. They bid for the chance to work with you. You pick the best one, and then you sign the contract with them. Once the work begins, you monitor it to make sure that the contract is being followed. When the work is done, you close out the contract and fill out all the paperwork.

You need to start with a plan for the whole project. Before doing anything else, you need to think about all of the work that you will contract out for your project. You will want to plan for any purchases and acquisitions. Here’s where you take a close look at your needs to be sure that contracting is necessary. You figure out what kinds of contracts make sense for your project, and you try to define all of the parts of the project that will be contracted out.

Contract planning is where you plan out each individual contract for the project work. You work out how you’ll manage the contract, what metrics it will need to meet to be considered successful, how you’ll pick a seller, and how you’ll administer the contract once the work is happening.

The procurement process helps companies obtain and manage costs related to freight, human resources, capital assets, fuel, IT equipment, sales, utilities, marketing, legal and professional services, raw materials, and facility management.

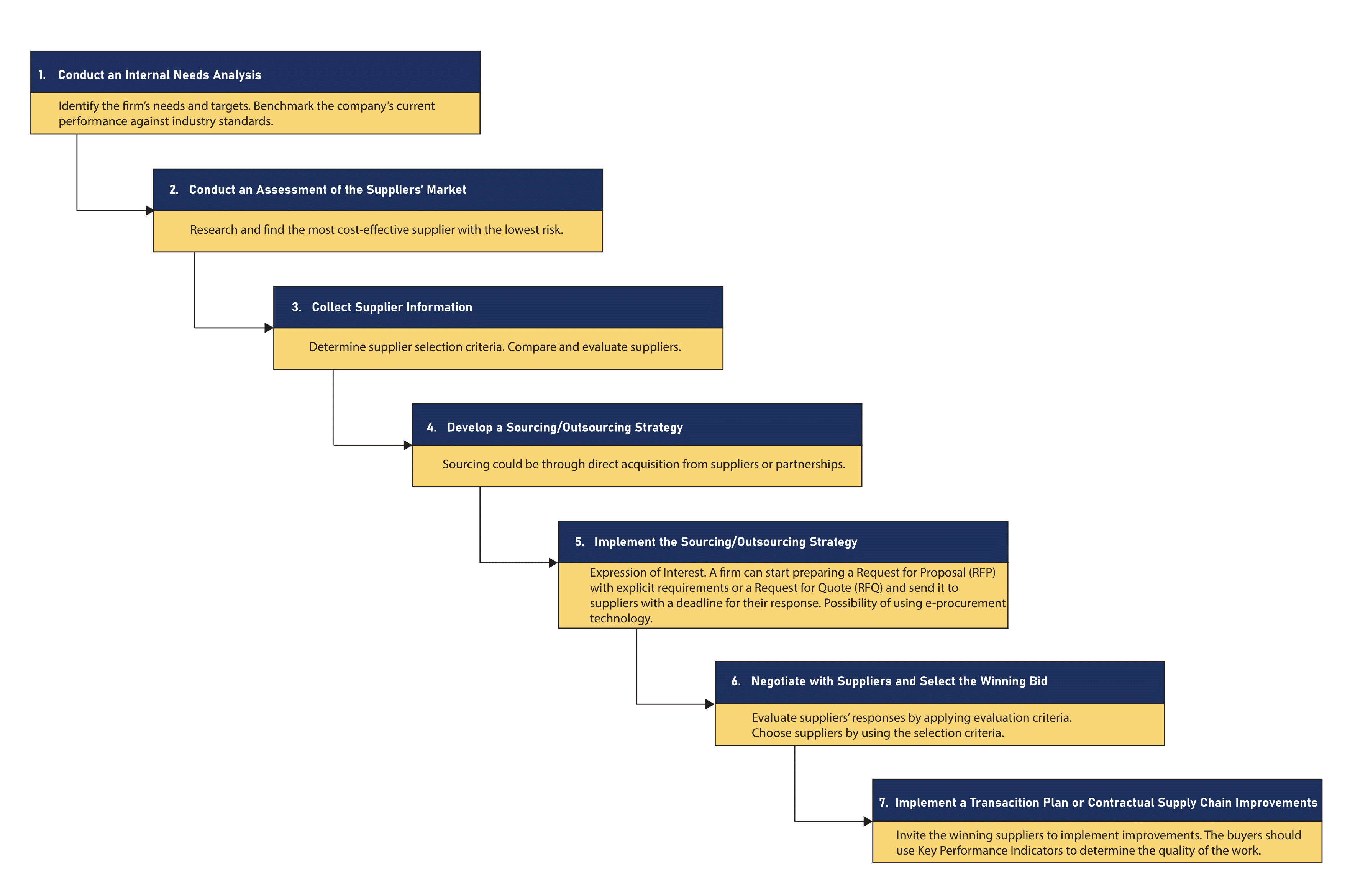

According to FITT’s “Global Value Chain” (2021), there are seven major steps in the procurement process. They are visualized in Exhibit 5.1.

Sourcing and Outsourcing of Goods, Manufacturing, and Services

The Canadian government is committed to modernizing procurement and has evolved from sourcing products domestically to global sourcing and outsourcing manufacturing, and services. Companies cannot manufacture all the products and do all the services needed to run a business and hold a competitive position in the market. That is why many organizations use sourcing and outsourcing strategies and become globally competitive. Other benefits accrued include cost reduction, increasing efficiency by meeting customer demands on time, taking advantage of different time zones, accessing cutting-edge technology, cheap cost of labour, increase in innovation and shared expertise, improved quality of products/services, access to talents and experts, and so forth. Examples of big companies that outsource include Google, Apple, Skype, Alibaba, etc. Let’s delve deeper into the definitions of sourcing and outsourcing of goods, manufacturing and services.

Sourcing

Sourcing is a process of obtaining goods or services from a particular place.

Here is a clear explanation of sourcing adapted from Babu John Mariadoss’s Global Sourcing and Distribution.

Global sourcing refers to buying the raw materials or components that go into a company’s products from around the world. For example, Starbucks buys its coffee from locations like Colombia and Guatemala. The advantages of global sourcing are quality and lower cost. Global sourcing is possible to the extent that the world is flat—for example, buying the highest-quality cocoa beans for making chocolate or buying aluminum from Iceland, where it’s cheaper because it’s made using free geothermal energy.

When making global sourcing decisions, firms face a choice of whether to sole-source (i.e., use one supplier exclusively) or to multisource (i.e., use multiple suppliers). The advantage of sole sourcing is that the company will often get a lower price by giving all of its volume to one supplier. If the company gives the supplier a lot of business, the company may have more influence over the supplier for preferential treatment. For example, during a time of shortage or strained capacity, the supplier may give higher quantities to that company rather than to a competitor as a way of rewarding the company’s loyalty.

On the other hand, using multiple suppliers gives a company more flexibility. For instance, if there’s a natural disaster or other disruption at one of its suppliers, the company can turn to its other suppliers to meet its needs. For example, when Hurricane Mitch hit Honduras with 180-mile-per-hour winds, 70 to 80 percent of Honduras’s infrastructure was damaged, and 80 percent of its banana crop was lost. Both Dole Food Company and Chiquita bought bananas from Honduras, but Dole relied more heavily on bananas from Honduras than from other countries. As a result, Dole lost 25 percent of its global banana supply, but Chiquita lost only 15 percent.

Sole-Sourcing Advantages

- Price discounts based on higher volume

- Rewards for loyalty during tough times

- Exclusivity brings differentiation

- Greater influence with a supplier

Sole-Sourcing Disadvantages

- Higher risk of disruption

- Supplier has more negotiating power on price

Multisourcing Advantages

- More flexibility in times of disruption

- Negotiating lower rates by pitting one supplier against another

Multisourcing Disadvantages

- Quality across suppliers may be less uniform

- Less influence with each supplier

- Higher coordination and management costs

Whichever sourcing strategy a company chooses, it can reduce risk by visiting its suppliers regularly to ensure the quality of products and processes, the financial health of each supplier, and the supplier’s adherence to laws, safety regulations, and ethics.

Outsourcing

Outsourcing is the process or a situation when a company employs a third-party provider or organization to do some work instead of using its own staff or resources.

The difference between sourcing and outsourcing is that sourcing procures goods/products for running a business; on the other hand, outsourcing transfers a company’s function to a third-party provider or external service provider. A lot of Canadian companies, as well as the Canadian government, use outsourcing technology. For example, according to Forrester Research (2020), the Canadian government and businesses spent 15 billion dollars on technology outsourcing in 2021 (Forrester Research, 2020).

Advantages and Disadvantages of Outsourcing

Here are some advantages and disadvantages of outsourcing:

Advantages

- Lower costs

- Product differentiation

- Increased production capacity

- Ability to meet customer demands

- Efficient replenishment

- Focus on the core competencies

- Build innovative products or services

- Effective and efficient service

- Increase value by bringing capabilities and expertise

- Reduce operational and production costs

- Being adaptable to changing market conditions and preferences

- Increased human resources

- Low cost of labour

Disadvantages

- Exposes confidential information and technology

- Hidden costs

- Exchange rate fluctuations

- Lack of customer focus

- Cost of transactions can be raised

- Wrong partners

- Risk of cultural differences

- Risk of poor-quality finished products

- Delay in delivering goods or services

Outsourcing of Manufacturing

Globalization has significantly improved businesses by increasing the availability of labour and production flexibility. In addition, labour costs in many countries are cheap, which helps companies move their production process to third-party or external providers with whom the firm has a contract. As a result, companies can benefit from specialized resources and reduced fixed costs. For example, an airplane can be split into thousands of parts and produced in many geographic locations.

Here is a clear explanation of outsourcing adapted from Introduction to Business reading: “Outsourcing” by Linda Williams and Lumen Learning.

PowerSki’s Web site states that “PowerSki International has been founded to bring a new watercraft, the PowerSki Jetboard, and the engine technology behind it, to market.” That goal was reached in May 2003, when the firm emerged from a lengthy design period. Having already garnered praise for its innovative product, PowerSki was ready to begin mass-producing Jetboards. At this juncture, the management team made a strategic decision that’s not uncommon in manufacturing today.

Rather than producing Jetboards in-house, they opted for outsourcing: having outside vendors manufacture the engines, fiberglass hulls, and associated parts. Assembly of the final product took place in a manufacturing facility owned by All American Power Sports in Moses Lake, Washington. This decision does not mean that the company relinquished control over quality; in fact, every component that goes into the PowerSki Jetboard is manufactured to exact specifications set by PowerSki.

One advantage of outsourcing its production function is that the management team can thereby devote its attention to refining its product design and designing future products. However, as processes or pieces of a process are outsourced companies have legitimate concerns about quality standards being met and maintained at the outsourced location. The decision whether or not to outsource often comes down to identifying organizations that can meet and maintain the standards set by the company and the customer.

Understandably, outsourcing is becoming an increasingly popular option among manufacturers. For one thing, few companies have either the expertise or the inclination to produce everything needed to make a product. Today, more firms, like PowerSki, want to specialize in the processes that they perform best—and outsource the rest. Like PowerSki, they also want to take advantage of outsourcing by linking up with suppliers located in regions with lower labour costs.

Outsourcing of Services

Globalization allows organizations to be competitive and move data cost-effectively and very fast. In addition, technological advances help continue the trend toward outsourced services significantly. For example, according to Statista (2019), the trend toward outsourcing IT services continues to grow steadily.

Services can be outsourced in the following sectors:

- Administration: Administration services consist of business processes, public administration, security, procurement, accounting, finance and so forth.

- Infrastructure: Infrastructure services include communications services, information security, media and content, data processing, development of applications, and data storage.

- Knowledge: The knowledge segment includes product and service developments, research, analytics, inventory management, insurance processing, and software design.

Practical Procurement: Scenarios and Solutions

Robin Oke, the Chief Procurement Officer at Carter Technology Solutions, faced a critical decision. The company, known for its innovative tech products, was experiencing increased competition from global players. To maintain its market position, Robin needed to find ways to reduce costs and improve efficiency. The main business problem was whether to outsource certain functions to third-party providers or continue using in-house resources. This decision was crucial for Robin because it would impact the company’s ability to compete globally and meet customer demands.

Carter Technology Solutions, headquartered in Toronto, Canada, specialized in developing and manufacturing high-tech gadgets and software solutions. With a workforce of 1,200 employees, the company served a diverse customer base, including individual consumers, businesses, and government agencies. Carter Technology generated revenue through the sale of its products and services, as well as through maintenance contracts and software subscriptions. The company prided itself on its ability to innovate and deliver high-quality products, but the increasing costs of production and the need for rapid scalability were becoming significant challenges.

Robin considered three main options to address the company’s challenges. The first option was to outsource the manufacturing of certain components to a third-party provider in Asia. This option promised lower labour costs and increased production capacity, allowing Carter Technology to meet growing customer demands. However, it also posed risks, such as potential quality issues and cultural differences that could affect the final product.

The second option was to outsource the company’s IT support and customer service functions to a specialized firm in India. This move could reduce operational costs and allow Carter Technology to focus on its core competencies, such as product development and innovation. On the downside, this option could expose confidential information and lead to a lack of customer focus, potentially harming the company’s reputation.

The third option was to keep all functions in-house but invest in new technologies and training programs to improve efficiency. This approach would ensure that Carter Technology maintained control over its processes and quality standards. However, it required significant upfront investment and might not provide the immediate cost savings needed to stay competitive in the short term.

Robin needed to make a decision quickly to ensure that Carter Technology could adapt to the changing market conditions and continue to thrive. The choice between outsourcing and maintaining in-house operations was not just about cost savings; it was about positioning the company for future growth and success.

Discussion Questions

- What are the potential advantages and disadvantages of outsourcing the manufacturing of components to a third-party provider in Asia for Carter Technology Solutions?

- How might outsourcing IT support and customer service functions impact Carter Technology Solutions’ ability to focus on its core competencies and maintain customer satisfaction?

- What factors should Robin consider when deciding whether to invest in new technologies and training programs to improve in-house efficiency versus outsourcing?

Source: Scenario and questions created with the assistance of Microsoft Copilot.

Public Procurement Playbook

As countries like China and India become leaders in manufacturing, the costs of their expertise rise, diminishing their advantage against North American counterparts. Adversely, convoluted and increasingly risky supply chains dependent on inexperienced vendors have turned once-stable brands like Boeing into the perfect “reshoring” case study.

Source:

Minute MBA by OnlineMBA.com. [2013, May 28]. Why Outsourcing is Bad for Business [Video]. YouTube. https://youtu.be/V7fsEIp2r_8?si=N03IqE0vRcH_Bi6i

Checkpoint 5.1

Image Description

Exhibit 5.1: The image displays a seven-step process diagram for supplier selection and sourcing strategy. Each step comprises a blue title box followed by a connected yellow description box. The steps are sequentially connected by arrows, indicating the flow of the process from top left to bottom right. The background is white, and the boxes are aligned diagonally, creating a staircase pattern.

- Conduct an Internal Needs Analysis: The title box is blue, stating the step number and title. Below, a yellow box includes the description, focusing on identifying firm needs and benchmarking against industry standards.

- Conduct an Assessment of the Suppliers’ Market: Similarly styled blue and yellow boxes detail the research for cost-effective suppliers with low risk.

- Collect Supplier Information: This section includes criteria determination and supplier evaluation.

- Develop a Sourcing/Outsourcing Strategy: Text discusses sourcing options, either directly or through partnerships.

- Implement the Sourcing/Outsourcing Strategy: Emphasizes preparing RFPs or RFQs and possible e-procurement use.

- Negotiate with Suppliers and Select the Winning Bid: Describes evaluation of supplier responses using selected criteria.

- Implement a Transaction Plan or Contractual Supply Chain Improvements: Discusses inviting suppliers for improvements and applying KPIs.

Attributions:

“5.1: Globalization of Procurement, Sourcing, and Outsourcing” is a remix and adaptation of “Chapter 3: International Procurement” from Global Value Chain, copyright © 2022 by Kiranjot Kaur and Iuliia Kau, licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License, except where otherwise noted.

Exhibit 5.1 is adapted from Figure 3.1: Procurement Flow Chart in “3.2 Concept of Procurement and its Value in the Global Value Chain” from Global Value Chain, copyright © 2022 by Kiranjot Kaur and Iuliia Kau, licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License, except where otherwise noted. This rendition copyright © 2024 Conestoga College, CC BY-NC-SA 4.0.

A clear explanation of the procurement process for services such as project management is taken from “Chapter 13 Procurement Management” from Project Management, copyright © 2014 by Adrienne Watt and is used under a Creative Commons Attribution 4.0 International License except where otherwise noted.

A clear explanation of sourcing is taken from “10.3 Global Sourcing and Distribution” from Core Principles of International Marketing by Babu John Mariadoss and is used under a Creative Commons Attribution-NonCommercial-ShareAlike License 4.0, except where otherwise noted.

A clear explanation of outsourcing is taken from “Outsourcing” by Linda Williams and Lumen Learning is taken from Introduction to Business and is used under a Creative Commons Attribution-NonCommercial-ShareAlike License 4.0, except where otherwise noted.

“Practical Procurement: Scenarios and Solutions” box was created with the assistance of Microsoft Copilot and is shared under the Creative Commons – CC0 1.0 Universal License.

The multiple choice questions in the Checkpoint boxes were created using the output from the Arizona State University Question Generator tool and are shared under the Creative Commons – CC0 1.0 Universal License.

Image descriptions and alt text for the exhibits were created using the Arizona State University Image Accessibility Creator and are shared under the Creative Commons – CC0 1.0 Universal License.

Activities that revolve around identifying and assessing potential suppliers that offer the best value.

The process or a situation when the company employs a third-party provider or organization to do some work instead of using its staff or resources.