5.10 Case Study: All Mats Services

Case Study: All Mats Services

All Mats Services is a sizable family-owned workshop in Mississauga that offers cleaning and repair services for factories, garages, hospitals, retailers and offices in GTA and beyond. The shop was founded and is owned by Ali Karami, who started this business in 1975 by going to repair shops, collecting their door mats to wash them in his small pick-up truck. In nearly two decades, he expanded his operation to what it is today. Crucial to his business success was his keen attention to fine detailing and rejuvenating old mats, which brought him a sound reputation among the clients he served.

The bulk of All Mats orders come for cleaning rubber-based mats and runners. Equipped with the latest cleaning machinery, the workshop operates 8 hours a day, five days a week (Monday-Friday) throughout the year. Rooted in Ali’s reputation with refurbishing plush products (door mat, runners, area mats/rugs), the shop also accepts cleaning orders of these products.

Although Ali is satisfied with his operational revenue, he sometimes gets upset about the backlog of orders that could negatively impact the efficient and timely delivery of the finished jobs to some clients. As an expediting measure, the shop receives the orders in a rolled bundle tagged for each client and delivers the finished jobs in the same manner and using the same tags. In an attempt to manage efficient and timely delivery and improve his operation, Ali has hired your group as consultants to examine the All Mats operations and offer recommended solutions. Last Monday, your group held a meeting in his office where he provided the following operational details.

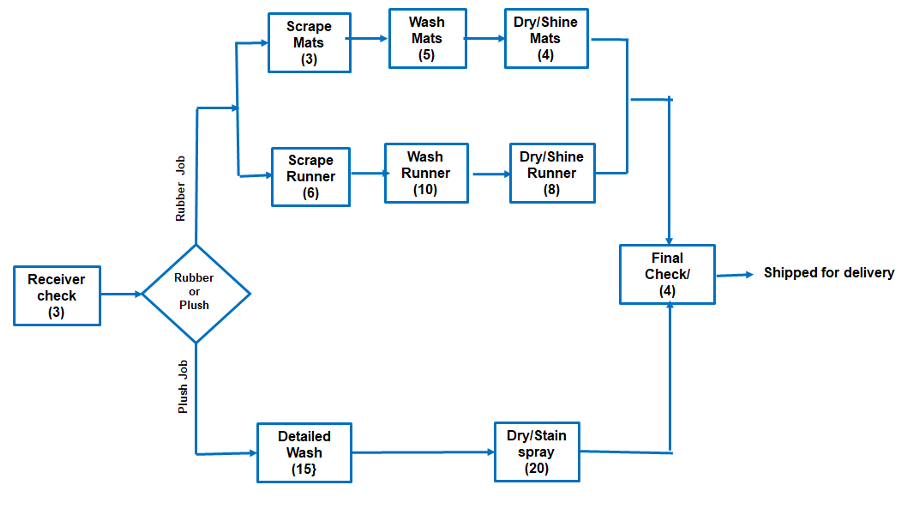

“I am very obsessed with clean delivery of finished jobs, so all jobs come into the shop floor in our trucks, bundled and tagged by order number and client’s name and when finished, shipped out in our own trucks.” Ali continued, “Upon arrival, bundles are inspected by our receivers to make sure they are all good. On average, this is done in about 5 minutes. After that, jobs would be divided into two categories: a) Rubber and b) Plush. All rubber jobs will go through three processes: scraping, washing and dry/shine. Now let’s walk through the shop and see them done in action,” said Ali. During your tour of rubber operations, you noted that in the “scraping” stage, mats and runners were guided through scraper rollers to remove debris from the grooved surface (e.g., gum, duct tapes, sand, etc.) from the surface. Different scrapers were used for mats and runners. You were told that on average, bundles of runners and mats were scarped in 6 minutes and 3 minutes, respectively. Next, bundles of mats and runners were washed in separate machines. You were told that machine washing of runner and mat bundles is completed in 10 and 5 minutes, respectively. All washed rubber jobs were dried under pressure air and then surface-coated with a shine spray. You were advised that these activities are completed on average in 8 minutes and 4 minutes for runners and mats, respectively.

Ali’s brother, Abbas, took your group for a tour of the Plush operation, and you noted that bundles first went through a detailed wash, whereby they were washed four times with different chemicals to remove dirt and stains. Next, they were dried through heat rollers and hot air blowers and sprayed with stain guard. You were told that washing and drying plush bundles would, on average, take 15 and 20 minutes, respectively.

At the end of your tour, Ali and Abbas told you that they ensure all the rubber and plush jobs are carefully checked for quality before they are shipped to the customer. “On average, we spent about 5 minutes on each bundle to make sure the outgoing bundles are clean, dry, treated and tagged properly”. You asked them how many of each job order they receive. Ali said the number of orders slightly changes at different times of the year, but ballpark 80% of their orders are rubber jobs and 20% are for plush. You asked about the breakdown of rubber orders, and they said mats and runners each form 40% of orders.

Ali then invited you back to his office, offered you coffee. After coffee, he said: “I am rather content with my business, but at times, particularly in winter, we take more jobs and I sometimes worry that we might fall behind. I don’t know, perhaps it would be helpful to have a map of our operation to figure out what can give us a headache and what needs to be done about it.

Source: (Haywood, 2023).

Question

How would you help him by drawing a process flow diagram of their operations?

Image Description

A flowchart showing a process for handling jobs with two main paths: rubber jobs and plush jobs. The process begins with a “Receiver check (3).” A decision diamond labelled “Rubber or Plush” splits the flow.Numbers in parentheses indicate processing times or steps.

Rubber Job Path:

Two sub-paths:

- Scrape Mats (3) → Wash Mats (5) → Dry/Shine Mats (4).

- Scrape Runner (6) → Wash Runner (10) → Dry/Shine Runner (8).

Both sub-paths lead to “Final Check (4).”

Plush Job Path:

- Detailed Wash (15) → Dry/Stain Spray (20) → Final Check (4).

All paths converge at “Final Check (4)” before proceeding to “Shipped for delivery.”