6.4 Quality Systems

Many organizations employ various quality systems to manage and enhance their quality standards. Three common quality systems are Total Quality Management (TQM), ISO 9001, and Six Sigma.

Total Quality Management (TQM)

In today’s competitive environment, companies must deliver high-quality goods and services that meet or exceed customer expectations. Total Quality Management (TQM), also known as quality assurance, encompasses all the steps a company takes to ensure its products or services align with customer-defined specifications and maintain high quality. TQM principles generally focus on three key areas:

- Customer satisfaction

- Employee involvement

- Continuous improvement

Let’s delve deeper into these principles.

Customer Satisfaction

Organizations committed to TQM recognize that the primary goal of a business is to generate profit by fulfilling customer needs. They allow customers to define quality by identifying and offering product features that meet their requirements. These companies actively seek customer feedback to understand how to produce goods and services that function correctly and meet expectations.

To ensure quality is integrated into every aspect of their operations—from design and product planning to sales and service—companies often use surveys and other methods to monitor customer satisfaction. By tracking feedback over time, they can identify areas for improvement.

Employee Involvement

Effective TQM requires the commitment of everyone in the organization, not just upper management, to satisfy the customer. For instance, if customers experience long wait times at a drive-through, multiple employees are responsible, not just the manager. Similarly, a defective DVD is not solely the responsibility of the quality control department but of every employee involved in its design, production, and shipping.

Managers must communicate the importance of quality to all employees and motivate them to focus on customer satisfaction. Employees need proper training to perform their jobs effectively and to identify and correct quality issues. In many organizations, employees working in similar roles form teams, often called quality circles, to identify work-related problems, propose solutions, and collaborate with management to implement their recommendations.

Continuous Improvement

A core component of TQM is continuous improvement, which involves a commitment to constantly enhancing the design, production, and delivery of goods and services. There are always opportunities to increase efficiency, reduce costs, and improve customer service and satisfaction. Everyone in the organization is encouraged to seek ways to do things better.

By adhering to these TQM principles, organizations can consistently deliver high-quality products and services that meet customer needs and maintain a competitive edge in the market.

ISO Standards

The International Organization for Standardization (ISO) is an independent, non-governmental organization that develops and publishes voluntary international standards. Founded in 1947 and headquartered in Geneva, Switzerland, ISO operates in 164 countries and is the largest developer of international standards.

The primary objective of ISO standards is to promote global proprietary, industrial, and commercial standards that facilitate trade and ensure the safety, reliability, and quality of products and services. By enabling direct comparisons between products from different markets, these standards assist businesses in entering new markets and contribute to developing fair global trade practices.

Additionally, ISO standards serve to safeguard consumers and end-users by ensuring that certified products and services conform to internationally established minimum standards. Using these standards helps organizations create safe, reliable, and high-quality offerings while increasing productivity and minimizing errors and waste.

Video: “What ISO standards do for you” by ISO [2:05] is licensed under the Standard YouTube License. Transcript and closed captions available on YouTube.

Steps in Obtaining ISO Certification

To obtain ISO certification, an organization must follow a structured process:

- Documentation and Implementation: The organization must document and implement its quality management systems, including policies, procedures, and work instructions. This documentation process can be time-consuming and requires collaboration from all employees.

- Quality Manual: The organization must develop a Quality Manual that outlines how it will ensure the quality of its goods and services.

- Employee Training: All employees involved in the documented processes must receive comprehensive training to gain a full understanding of the new work procedures and documentation.

The cost and duration of this process depend on the size and complexity of the organization. Many firms choose to engage external consultants to guide and assist them throughout the process, which typically takes 12 to 18 months. ISO certification is valid for three years, after which the organization must undergo a recertification process.

While some organizations pursue ISO certification primarily due to customer requirements, the intrinsic motivation should be a genuine desire to improve internal performance and quality standards.

What Benefits Are There to Obtaining ISO Certification?

ISO (International Organization for Standardization) certification is a globally recognized standard demonstrating an organization’s commitment to quality, efficiency, and continuous improvement. Pursuing and maintaining ISO certification can provide organizations with the following benefits:

- Enhanced Quality Management: ISO standards, such as ISO 9001, provide a framework for establishing a robust quality management system (QMS). Organizations can streamline their processes by implementing these standards: identify and monitor key performance indicators and maintain consistent quality standards across their operations. This leads to improved product or service quality, increased customer satisfaction, and a competitive advantage in the market.

- Operational Efficiency and Cost Savings: Adhering to ISO standards encourages organizations to optimize processes, reduce waste, and improve overall efficiency. Organizations can achieve cost savings, increased productivity, and a more agile and responsive operational structure by identifying and eliminating non-value-adding activities.

- Risk Management and Compliance: ISO standards emphasize risk-based thinking and provide guidelines for identifying, assessing, and mitigating potential risks. Organizations can proactively manage risks, ensure regulatory compliance, and protect their employees, assets, and reputation by implementing standards like ISO 31000 (Risk Management) and ISO 45001 (Occupational Health and Safety Management System).

- Expanded Market Access: ISO certifications serve as a globally recognized symbol of quality and compliance. Organizations that achieve ISO certifications, such as ISO 9001 or ISO 13485 (Medical Devices), demonstrate their commitment to meeting internationally recognized standards. This enhances credibility and opens doors to new markets by reassuring customers, suppliers, and partners about the organization’s dedication to quality and industry best practices.

- Continuous Improvement Culture: ISO standards foster a culture of continuous improvement by promoting the Plan-Do-Check-Act (PDCA) cycle. Organizations that embrace ISO standards are encouraged to regularly evaluate their processes, measure performance, and implement corrective actions. This iterative approach drives ongoing optimization, innovation, and the pursuit of excellence within the organization.

- Increased Customer Confidence: ISO standards instill confidence by ensuring organizations follow standardized processes, prioritize customer satisfaction, and deliver reliable products or services. Standards like ISO 27001 (Information Security Management System) and ISO 22301 (Business Continuity Management System) address data security and business continuity, strengthening customer trust in handling sensitive information and ensuring uninterrupted operations.

- Improved Communication and Corporate Culture: Implementing ISO standards promotes better communication and alignment within the organization. By having a set of standardized processes and quality objectives, employees clearly understand their roles and responsibilities, leading to improved collaboration and a stronger corporate culture focused on quality and customer satisfaction.

By pursuing and maintaining ISO certification, organizations can enhance their operations, reduce risks, and gain a competitive edge in the market, making it a valuable investment for operations management professionals. (Diesing, 2023; Onspring, n.d.)

Read the article below from the Business Development Bank of Canada.

Hazard Analysis Critical Control Point (HACCP)

HACCP is a quality management system specifically designed for organizations in the food processing industry. Implementing a HACCP program can yield several significant benefits:

- Gain Customer Confidence: Demonstrating a commitment to food safety can enhance customer trust.

- Sharpen Competitive Edge and Develop New Export Opportunities: Adhering to HACCP standards can differentiate your business and open up new markets.

- Achieve More Rigorous Quality Control: Implementing HACCP ensures stringent quality control measures are in place.

- Reduce Waste and Spoilage: Effective management of food safety risks can minimize waste and spoilage.

- Control Contamination Risks and Recall Processes: HACCP helps identify and control contamination risks, thereby streamlining recall processes if necessary.

- Build Awareness of Hygiene and Safety for Employees: Training employees on HACCP principles increases their awareness of hygiene and safety practices.

- Eliminate Potential Allergen Issues: HACCP helps identify and manage potential allergen risks.

The Seven Principles of HACCP

The seven principles of HACCP outline the steps necessary to manage and control food safety risks within a business:

- Conduct a Hazard Analysis: Identify potential hazards affecting food safety.

- Identify Critical Control Points (CCPs): Determine the points in the process where hazards can be prevented, eliminated, or reduced to safe levels.

- Establish Critical Limits: Set maximum or minimum limits for each CCP to ensure food safety.

- Monitor Critical Control Points: Implement procedures to monitor CCPs and ensure they remain within the established limits.

- Establish Corrective Actions: When monitoring indicates a CCP is not within the established limits, define actions to be taken.

- Establish Record-Keeping Procedures: Maintain documentation and records to demonstrate compliance with HACCP principles.

- Establish Verification Procedures: Implement procedures to verify that the HACCP system is working effectively.

Ensuring the safety of customers is paramount for any food business. Organizations can control food safety risks and protect against foodborne illness outbreaks by implementing a successful HACCP program. Since 2005, it has been mandatory for federally registered meat and poultry establishments to become HACCP-certified. The Canadian Food Inspection Agency also recommends HACCP compliance certification for all businesses within the food supply chain.

Video: “HACCP – Making Food Products Safe, Part 1” by Alberta Agriculture and Irrigation [15:06] is licensed under the Standard YouTube License. Transcript and closed captions available on YouTube.

Six Sigma

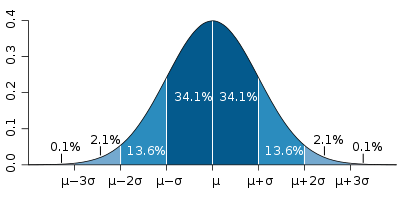

In your career, you may find yourself working in an organization that has adopted a Six Sigma program. Six Sigma is a comprehensive set of techniques and tools designed for process improvement. It was introduced by engineer Bill Smith at Motorola in 1980. The primary goal of Six Sigma is to achieve business success by minimizing variation in business processes. The term “Six Sigma quality” refers to a process that is so well-controlled that it produces no more than 3.4 defects per million opportunities.

The concept of Six Sigma is rooted in statistics, where “sigma” denotes standard deviation, a measure of variation within a dataset. Typically, a company process might operate at a 3-sigma quality level, meaning that 99.73% of all output falls within plus or minus three standard deviations from the mean. This results in 0.27% of all outputs being non-conforming or defective, which equates to 2,700 defects per million opportunities. Such a defect rate is unacceptable in industries where quality is critical to customer safety, such as manufacturing aircraft, automobiles, or medical devices. In contrast, a Six Sigma process achieves 99.99966% defect-free outputs.

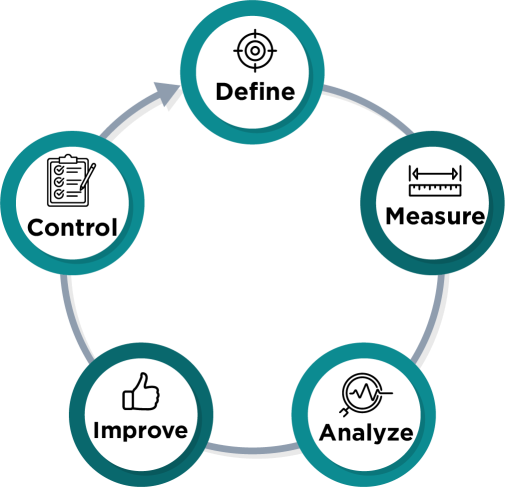

The DMAIC Improvement Model

Unique to Six Sigma is the DMAIC Improvement Model, which stands for Define, Measure, Analyze, Improve, and Control. In Six Sigma, improvements are driven by project teams assembled to address quality issues, streamline existing processes, or develop new processes. The DMAIC model guides these teams through a structured approach to process improvement (American Society for Quality, n.d.):

- Define: Identify the problem by understanding who the customer is, what their needs are, and what is most important to them. Determine the most suitable project to improve and meet customer requirements.

- Measure: Assess current process performance by collecting data and comparing it to the desired state. Use tools like Pareto charts to analyze the frequency of problems or causes.

- Analyze: Investigate the process to identify why defects are occurring and determine the causes of variation and poor performance. Conduct root cause analysis to pinpoint these issues.

- Improve: Enhance process performance by eliminating the causes of defects. Modify the process and measure the results to ensure the problem has been resolved.

- Control: Implement a plan to maintain the improved process and ensure that the gains are sustained over time.

By following the DMAIC model, organizations can systematically improve their processes, reduce defects, and enhance overall quality, leading to increased customer satisfaction and business success.

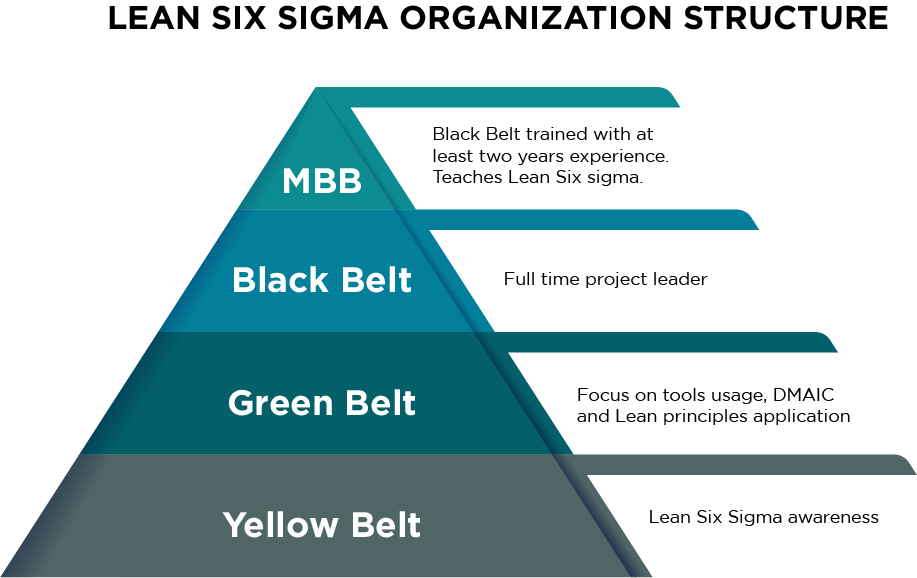

Six Sigma Belt Levels

Another unique aspect of Six Sigma is the use of a belt system, similar to martial arts, to symbolize an individual’s level of expertise and proficiency in Six Sigma methodologies. The belt levels are as follows:

- Green Belt: A Green Belt designation indicates that an individual has received Six Sigma training. Green Belts typically have full-time roles within the organization but are called upon to assist with Six Sigma projects part-time. They support project teams by applying Six Sigma tools and techniques under the guidance of more experienced Black Belts.

- Black Belt: A Black Belt is a full-time position within the quality department, where the individual works exclusively as a coach and leader for Six Sigma projects. Black Belts possess extensive experience in Six Sigma methodologies and spend the majority of their time leading project teams, providing guidance, and ensuring the successful implementation of Six Sigma initiatives.

- Master Black Belt: A Master Black Belt is a full-time position within the Six Sigma team, with extensive experience managing and overseeing Six Sigma projects. Master Black Belts serve as coaches and mentors to Black Belts, providing advanced training, guidance, and support in implementing complex Six Sigma projects.

- Champion: A Champion is typically a senior manager or executive overseeing the Six Sigma program and its associated personnel. Champions are responsible for determining which projects should be prioritized, ensuring proper allocation of resources, and removing any roadblocks that may hinder the success of Six Sigma initiatives. They play a crucial role in promoting and supporting the Six Sigma culture within the organization.

This belt system recognizes an individual’s level of expertise and defines their roles and responsibilities within the Six Sigma program. It fosters a structured approach to continuous improvement. It ensures that Six Sigma projects are led by qualified and experienced professionals, ultimately contributing to the organization’s overall quality and operational excellence.

“5 Managing Quality” from Introduction to Operations Management Copyright © by Hamid Faramarzi and Mary Drane is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License, except where otherwise noted.—Modifications: used section Quality Systems; some paragraphs rewritten; added additional explanations.