5.2 Sustainability in Food Service

In food services, there are many opportunities to engage in sustainable practices, such as energy conservation, managing and reducing food waste, composting, water conservation, recycling, reducing packaging, organic chemicals, and purchasing locally to reduce the carbon footprint of transportation of goods.

Energy Conservation and Management

Food Services typically consume five times more energy per square foot than other commercial buildings. This provides the Nutrition and Food Service Manager an opportunity to review current energy consumption and seek out opportunities for energy savings and conservation. Engaging in energy conservation programs can improve profitability, reduce the organization’s carbon footprint, and conserve natural resources for future generations. These goals align with the three pillars of sustainability.

Equipment

One of the quickest ways to conserve energy is to upgrade older kitchen equipment to Energy Star-rated equipment. Energy Star is an internationally recognized program. The label guarantees the consumer that the product has been certified to use less energy and reduce emissions that affect climate change.

Heating Ventilation & Air Conditioning (HVAC)

HVAC systems can be 28 to 35% of the total energy cost in commercial food service, making them a key area to evaluate for possible energy conservation. The following identifies ways to reduce HVAC costs:

- Ensure that the HVAC system is part of the preventative maintenance program. The HVAC system should be inspected twice annually – in the preheating season and the precooling season – to ensure that the system is in good working order and that filters have been changed.

- The Nutrition and Food Service Manager should complete a visual inspection to ensure that there is free airflow to and from the supply registers. Make sure that registers are not blocked by equipment or other materials.

- Keep electronic and heat sources away from thermostats.

- Educate staff to use window shades to block excess heat from direct sunlight.

- Use a smart thermometer that can be programmed to precool or preheat spaces an hour prior to occupation. Avoid heating or cooling unoccupied spaces.

- Consider a heat pump to decrease the cost of cooling and heating.

- Consider demand hoods. Demand hoods only actively engage in ventilation when heat or air debris (smoke) levels are detected in the kitchen.

Did you know that reducing energy costs by 20% could lead to a 33% increase in profitability?

Lighting

Lighting makes up approximately 10 to 15% of overall energy costs in commercial food service. Switching from traditional incandescent light bulbs to light-emitting diodes (LED) can result in using up to 90% less energy, which equals lower energy costs (Government of Canada, 2025). Installing occupy sensors is another way to lower energy costs. Occupy sensors will automatically turn the lights out when no movement is detected in the room after a set period.

Managing and Reducing Food Waste

Food waste is food that is discarded instead of consumed even though the food meets the standard for human consumption. This includes food that is left on plates served to clients, food leftover from service that was not served to clients and food that spoils in storage before it can be used in production.

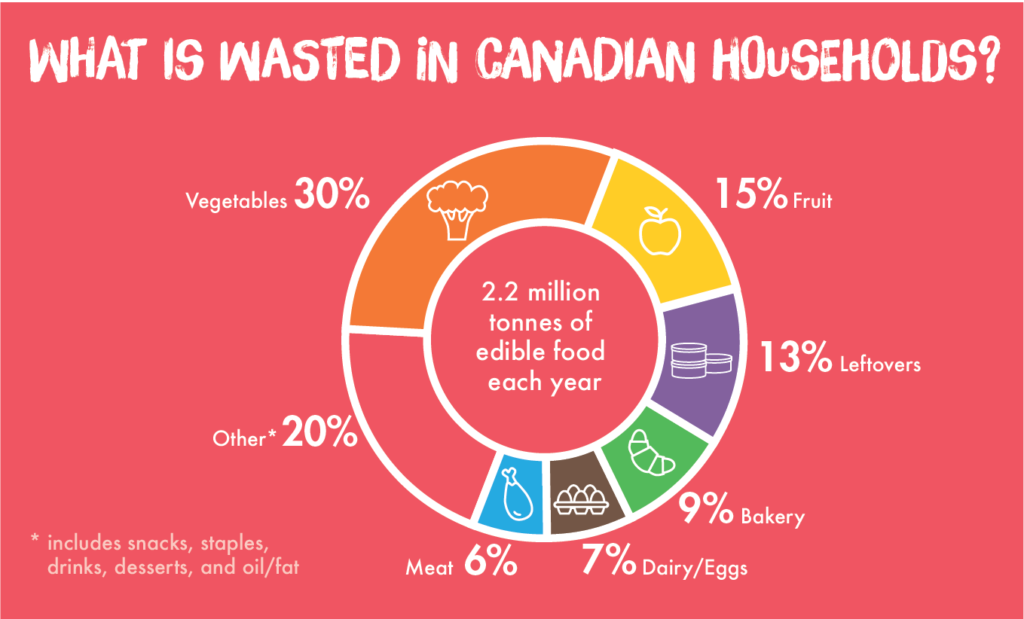

Recent research estimates that 20% (or 11 million tonnes) of all the food produced in Canada annually becomes avoidable food loss or waste – food that could have been eaten but was instead landfilled, incinerated or managed as organic waste (VCMI, 2019).

Image Description

Presents data on food waste in Canadian households, highlighting that 2.2 million tonnes of edible food are wasted yearly. It breaks down food waste by category and percentage:

Vegetables: 30% (largest category)

Fruit: 15%

Leftovers: 13%

Bakery items: 9%

Dairy & Eggs: 7%

Meat: 6%

Other (snacks, staples, drinks, desserts, oils/fats): 20%

Strategies for Decreasing Food Waste

Strategies include food waste prevention and food waste management. Food waste prevention includes preparing less food, using good storage practices, and purchasing in demand. Food waste management asks the question, what should we do with the leftovers?

Forecasting is the most accurate way to determine the correct amount of food preparation and production. Forecasting is the use of past information to predict future demand. For example, if the organization uses a cyclic menu, at some point, usually after 3 to 5 weeks, the menu will repeat itself. The repetition of the menu allows for forecasting. The last time that ham, scalloped potatoes, and beef stir fry were served, how many people chose ham and beef? Knowing that 40% of the people chose ham and 60% of the clients picked the beef stir fry means that you can, with a margin of error, predict how many clients will choose ham and how many will choose beef. If you are serving 120 clients at each meal, you can now forecast that 120 × 40% = 48 people will request ham, and 120 × 60% = 72 clients will ask for the beef stir fry. There is a small margin of error in forecasting, which has been determined to be approximately 10%. This means that you should instruct your cooks to prepare (48 × 10% = 4.8 or 5 portions) 48 + 5 = 53 portions of ham and scalloped potatoes.

Good storage practices are equal to training your staff on First In / First Out procedures and to correctly label and date all food items in storage. First In / First Out practices are just as they sound. When a food order arrives, the new items should be placed at the back of the storage area, and older items should be pulled forward to be used in food production first. Labelling and dating items are equally essential as they allow you and your staff to accurately track the shelf life of the food products.

Demand purchasing means purchasing only what is necessary to meet production needs. Remember that if you are working in a government-funded food service, such as healthcare, there is legislation that requires you to keep enough food on hand to feed everyone in the facility for three days should a shelter-in-place emergency occur at the facility. This food is above and beyond the food requirements for the regular meal service.

Flexibility in your menus means more opportunities to use products before they expire, spoil, and are discarded. Ask yourself if it is possible to substitute green beans for broccoli.

Food waste management encourages Nutrition and Food Service Managers to ask the following questions: What should we do with leftovers? Leftovers are untouched food that has not been served to a client and is left after the meal service has concluded. Rather than discard this food to the compost bin, can this food be offered to staff, perhaps for a discounted price? Or can this food be packaged and shipped to a local food bank or community program? Can any of the food be stored for use at a later date?

The key to a successful food waste reduction program, whether you choose to implement food waste prevention strategies, food waste management or both, is staff education and training. Training the staff on how to manage food waste and why sustainability is pertinent encourages collaboration and motivation to participate in food waste reduction practices.

Read more about food waste management in this article by EHL Hospitality Business School: Food Waste Management: Innovative Solutions for Hospitality

Read more about food waste management in this article by EHL Hospitality Business School: Food Waste Management: Innovative Solutions for Hospitality

Purchasing Local to Reduce Carbon Footprint

Carbon footprint is the total amount of greenhouse gases (GHGs) you emit into the atmosphere (BDC, n.d., para. 1).

Some of the GHGs measured are carbon dioxide (CO2), methane, and nitrous oxide. GHGs have been identified as contributing to a rise in the earth’s temperature. The rise in temperature, estimated to be between 1.5 and 2 degrees Celsius since 1970, has increased erratic weather patterns and the occurrence of natural disasters and provided numerous challenges for agricultural food producers (Government of Canada, 2020). The World Health Organization has set a net zero goal for carbon emissions. It is currently estimated that humans need to reduce or remove 20 billion tons of carbon from the atmosphere each year to reach the net zero goal (Climate Portal, 2023).

One of the ways to support this goal is to purchase local food products, as this decreases the distance the food needs to travel to get to your facility. Most food is moved around the world by average medium-duty trucks. The average truck, like the one that arrives at your workplace twice a week to deliver raw food products to you, is estimated to contribute 223 tons of CO2 per year (Kilgore, 2024).

Reducing the company’s carbon footprint begins with examining current purchasing practices and becoming knowledgeable about where the raw food products used in production are coming from. It means knowing the answer to the question: how far is the food travelling?