2.3 Food Production Systems

Food production systems consist of the inputs (equipment, food, skilled staff) used to create outputs (meals for clients). This section examines the advantages and disadvantages of four different types of food production systems: Conventional, Ready-Prepared, aka Cook-Chill, Commissary, aka Centralized Kitchen, and Assembly /Serve, aka Tray Line.

Conventional

In a conventional food production system, most menu items are prepared in a kitchen in the same facility where meals are served. Food preparation often begins with raw ingredients, which are prepared into menu items. In recent times, with advances and growth in commercial food production, shelf life, transportation, packaging, and holding techniques, the conventional system has evolved to include some ready-prepared menus.

Since this is the system that people tend to be the most familiar with there is a preconceived perception of a higher quality product being produced by a conventional system. This may or may not be true as it is dependent on several factors, including the skill level of the staff, the quality of the raw ingredients, and the efficiency of processes.

Absolute advantages do include the ability to control the quality of the raw product by means of procurement practices and receiving policy and procedures, adaptable menu item flexibility as menu items are not dependent on ready-prepared products, economical as ingredients can be purchased in season at lower prices and there is less costly freezer space required to support the menu.

Disadvantages can include a stressful workday for the staff due to peak demand periods and uneven workloads. Scheduling can also become difficult if skilled staff are required to perform specific tasks.

| Advantages | Disadvantages |

|---|---|

|

|

Ready-Prepared or Cook-Chill

Menu items are prepared in large quantities. Some are chilled and stored, ready for assembly and rethermalization. Rethermalization is the process used to bring chilled or frozen foods to a safe, hot consumption temperature before service. Some items are frozen for use at a later time. The separation between the time of preparation and service is the distinguishing characteristic of a Cook-Chill food production system.

The biggest advantage of the Cook-Chill food production system is control over the workload by eliminating the time crunch of service, which removes the stressful peak periods. This makes scheduling easier, which, in turn, leads to an increase in employee retention.

There is also an argument for improved nutrient retention, as individually quick-frozen vegetables have a higher nutrient value than fresh vegetables. According to a study, frozen fruits and vegetables have equal or greater nutritional value than their fresh cousins. This is in large part because fresh produce has been shown to decline in nutrients the longer it sits between harvesting and eating, whereas frozen produce stops its nutritive shot clock the moment its temperature drops (Bouzari et al., 2015).

Disadvantages include increased cost due to the equipment and storage space requirements for the products. Food safety requires additional diligence to ensure compliance. Any time the length of time between food production and service increases, there are more critical control points to monitor. Critical control points are points in the food production process when food hazards, such as allowing foods to remain in the temperature danger zone, can be eliminated or reduced to acceptable levels. Another disadvantage is that recipes may need to be scaled up and adjusted to produce the desired product. This means an increase in labour cost.

| Advantages | Disadvantages |

|---|---|

|

|

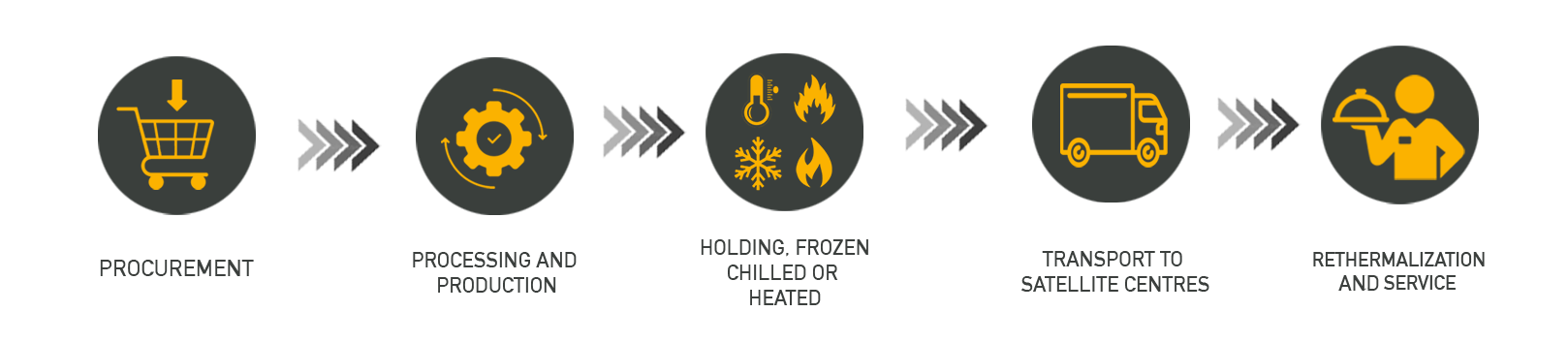

Commissary Centralized Kitchen

In a commissary food production system, menu items are prepared at a centralized kitchen facility and then moved to another site for final preparation and service. An example of this system is the Boulder Valley School District in Colorado, which has a centralized kitchen that produces meals that are served at over 40 different schools in the district.

Watch: Behind the Scenes of a Central Kitchen

Video: “Behind the Scenes of a Central Kitchen” by Chef Ann Foundation [23:09] is licensed under the Standard YouTube License. Transcript and closed captions available on YouTube.

Watch “Behind the Scenes of a Central Kitchen” by Chef Ann Foundation at https://www.youtube.com/watch?v=HiNaCU_oSVk

An advantage to commissary food production is cost savings due to large quantity production and purchases. There can also be a reduction in skilled labour cost. One skilled person can produce 200 eclairs at the centralized kitchen rather than 40 skilled cooks producing eclairs at each individual facility.

Disadvantages are the additional need for diligence to increase food safety critical control points, the additional cost of vehicles required for transportation, and the need to modify and scale large quantity recipes.

| Advantages | Disadvantages |

|---|---|

|

|

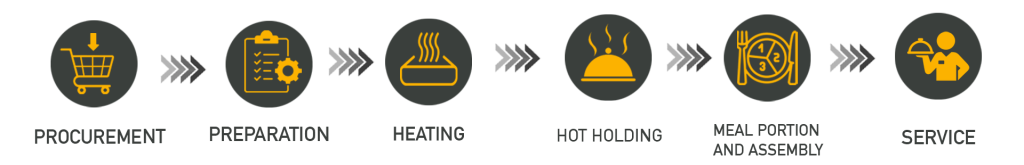

Assembly/Serve

The assembly service food production system is sometimes called the cookless kitchen because very few menu items are prepared onsite. Food is procured in a ready-to-serve form from commercial food companies, such as Nestle, Kraft Heinz, Campbell’s, and McCormick. You may recognize some of these brands for grocery store shelves. Production in the assembly service kitchen resembles a factory assembly line, with each staff member responsible for adding a particular item to each tray that passes by on the tray line.

This type of food production system saves money on labour costs, procurement costs, and waste. Less specialized capital equipment is required to provide food service. It is easier to schedule as there are fewer peak stressful work periods during each shift.

Disadvantages include limited menu adaptability and flexibility, making it tougher to provide substitutions for menu items. High cost for some menu items; for example, it costs approximately three times as much to purchase a prepared soup than it does to buy raw ingredients required for making a soup. This system requires additional freezer space, materials, and packaging.

The assembly serve food production system required consistent evaluation of food quality and portion sizes as it is common practice for food manufacturers to reduce the portion size of their product in an effort to maintain a competitive pricing model.

| Advantages | Disadvantages |

|---|---|

|

|

Choosing which type of food service production system to implement or whether or not to change to a different type of food service production system from the one you are currently working with can depend on many different factors. A good place to start thinking about this decision is to review the company’s mission and value statements and ask:

- Do the advantages of this type of food service production system align with the company’s overall goals?

- Do my food service values and goals align with the advantages of this system?

- Is there enough space to support this system?

- Can enough skilled staff be hired to support this system?

Frozen vegetable nutrients from: “Cold, Hard Harvest: Making the Case for Frozen Produce” by Nicco Pandolfi is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License, except where otherwise noted. -Modifications: Used paragraph 3 from section The Quality Pitch.