4.4 Developing and Maintaining a Preventative Maintenance Program

Step 1: Identify Assets

Step 2: Document Standard Operational Procedures for each piece of equipment

Step 3: Establish Maintenance Routines and Schedules

Step 4: Identify contact information for outside contractors

Step 5: Audit and Corrective Actions

Step 1: Identify Assets

Identify assets to be included in the preventative maintenance program by taking a physical inventory of the equipment in the facility. Include the following information in the physical inventory: Equipment Name, Serial No., Description and Location.

| Equipment | Serial No | Description | Location |

|---|---|---|---|

| Sierra Range | SR-60-10 | Commercial gas range with 10 burners, 2 x 32000 BTU ovens, stainless steel interior and exterior, porcelain oven decks and door liners, adjustable stainless steel legs | Main kitchen, first floor |

| Nor-Lake Kold Locker | KLB771014-C | 10 x 14 x 7.7 indoor walk-in cooler, 860 cubic feet of storage space, deadbolt locking handle with inside safety release, self-closing door, and digital thermometer | Main kitchen, first floor |

Step 2: Document Standard Operational Procedures

Sierra Range Standard Operating Procedures

For the oven:

- Set the desired temperature using a knob.

- Give the oven adequate time to achieve the desired set point.

- Using oven mitts, insert a sample (tray) to be heated into the oven and close the door. Ensure the door is completely shut.

- Once the sample has been heated for the prescribed duration (time), turn off the oven.

- Using oven mitts, remove the sample and place it on the counter.

For the stovetop:

- Depress and turn the gas burner to ignite.

- Select the desired temperature.

- Follow the recommendations for cooking temperatures and times.

- Remain in the room while operating the stovetop.

- Ensure ventilation openings are open and not covered.

- Switch the gas burners off immediately after use.

Step 3: Establish Maintenance Routines and Schedules

Routine cleaning by staff

The stovetop will be cleaned at the end of each day.

| Task | Date Complete | Date | Date | Date | Date | Date |

|---|---|---|---|---|---|---|

| Remove burner grates. Soak in hot, soapy water, scrub clean and air dry. | ||||||

| Wipe down exterior surfaces with a hot, soapy cloth. | ||||||

| Remove dip trays. Soak in hot, soapy water, scrub clean and air dry. |

Monthly visual inspection by staff

Complete the following inspection list on the first day of each month

| Task | Date | Date | Date | Date | Date | Date |

|---|---|---|---|---|---|---|

| Check oven temperature gauges using the digital oven thermometer. | ||||||

| Check gas flow. Even blue flames indicate good gas flow. Uneven orange flames indicate poor gas flow. | ||||||

| Check the function of the pilot lights. Do all the burners light? | ||||||

| Check the door hinges for a good seal. Does the door close completely? | ||||||

| Check the oven heating element. |

Annual gas testing inspection by a certified outside contractor: SERV-QUIP Equipment Service Contractor

Step 4: Identify contact information for outside contractors

Ensure that any outside contractors that you bring into work inside your facility are fully licensed and carry insurance for their work. For most skilled trades, this means having written and passed a certification of qualification examination for the trade. Keep contact information for local contractors in the preventative maintenance plan. Unless the contractor is coming directly from the manufacturer, then the local contractor should be located within a 50 km radius of the facility.

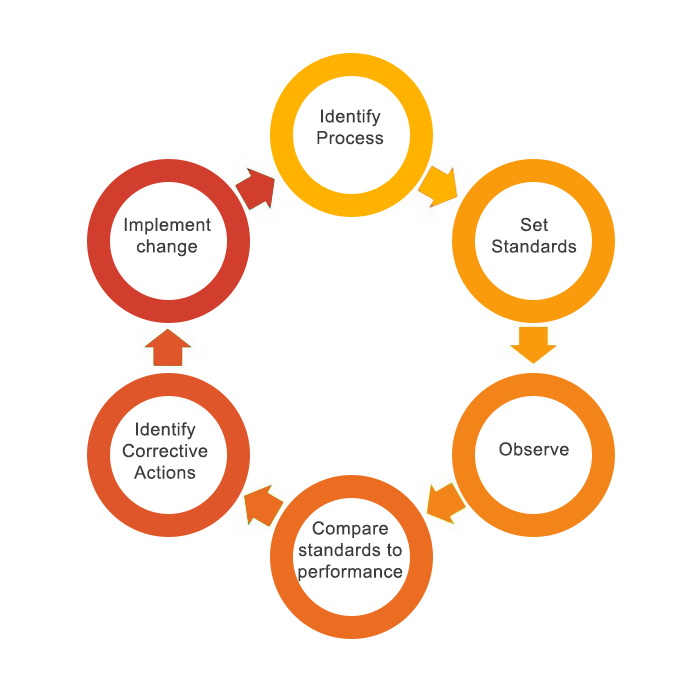

Step 5: Audit and Corrective Actions

An audit is an inspection process. The auditing process involves a list of standards that you expect to happen, observation of the process (inspecting oven function), comparison of standards to actual performance, identifying corrective actions and implementing change.