Chapter 9: Operations Management

Chapter 9 Learning Outcomes

After reading this chapter, you should be able to do the following:

- Explain how the production process creates finished products and services that provide value and utility to buyers.

- Explain how operations management is closely intertwined with the production process.

- Discuss how supply chain, value chain, and circular economy are intertwined.

- Discuss production planning, production control, and quality control as they pertain to manufacturing and service operations management.

- Explain how site selection, facility layout, and capacity are determined for both manufacturing and service organizations.

- Explain how outsourcing provides value to businesses and their customers.

- Explain the purpose of both PERT and Gantt charts.

- Discuss the technologies used by manufacturing organizations to produce and deliver goods in an efficient, cost-effective manner.

- Identify the characteristics that distinguish service operations from manufacturing operations.

- Discuss quality management as a strategy to improve productivity and customer satisfaction.

The Production Process

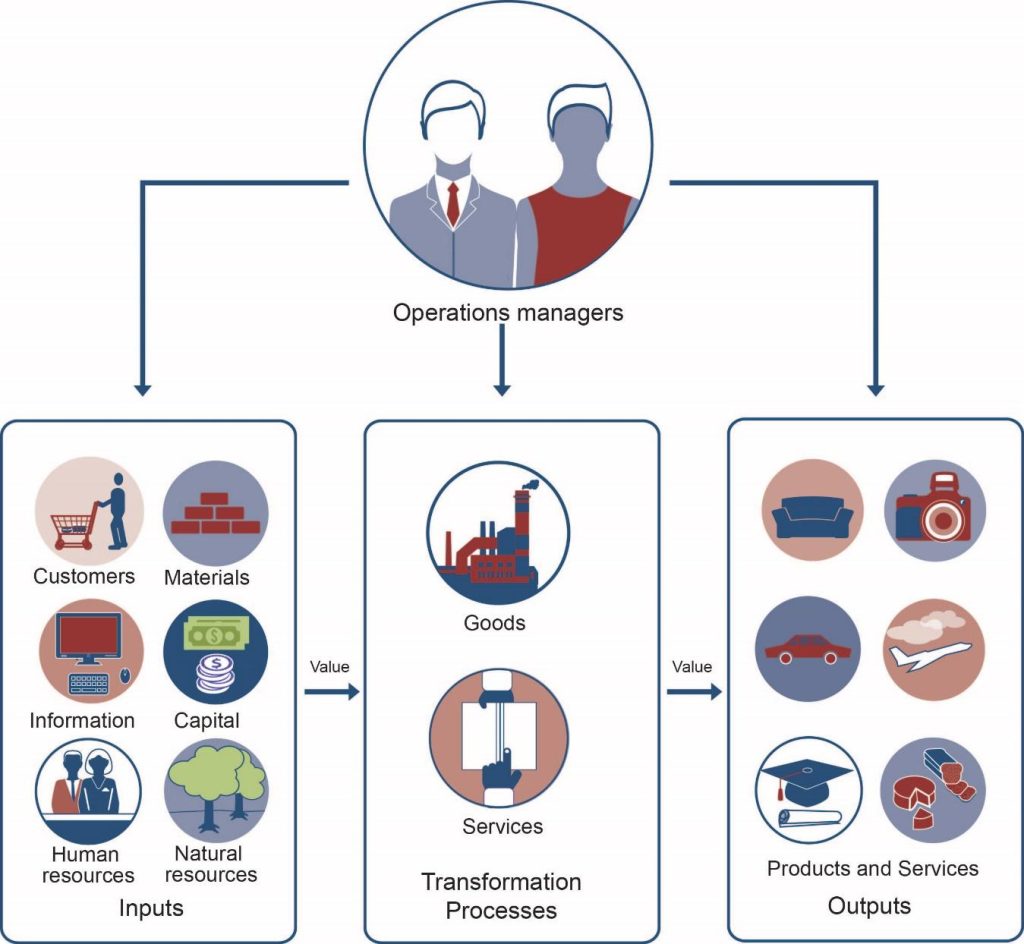

Every business that produces goods or services has a specific production process. Production refers to the process of transforming inputs (such as labour, capital, and raw materials) into outputs (goods and services) that a firm wishes to sell. Refer to the production transformation process in Figure 9.1.

The decisions made in the planning stage have long-range implications and are crucial to a firm’s success. Before making decisions about the operations process, managers must consider the goals set by marketing managers. Does the company intend to be a low-cost producer and to compete based on price? Or does it plan to focus on quality and go after the high end of the market? Many decisions involve trade-offs. For example, low cost doesn’t normally go hand in hand with high quality. All functions of the company must be aligned with the overall strategy to ensure success.

Value

The transformation process gives the finished products and services value. Value is the customer’s perception of the benefits they receive compared to the cost or effort required to obtain the product. It is subjective and influenced by factors like branding, emotional appeal, and customer experience. The value of the product or service equals the ratio of the product’s benefit to its cost (value = benefits/costs). The price you will pay for a product or service often depends on the benefits it brings and the value it has for you. Value is about how much the product matters to the customer (subjective).

Utility

Utility refers to the inherent usefulness or the ability of a product or service to satisfy a customer’s needs and wants. It is often measurable and tied directly to functionality. Utility is about what a product can do (objective).

There are four types of utility:

- Time utility. Availability when needed (e.g., seasonal availability of bathing suits)

- Place utility. Accessibility (e.g., location distribution of accessible)

- Form utility. Design (e.g., the design or structure meets needs)

- Ownership utility. Satisfaction (e.g., benefits of ownership, functional and emotional)

Companies can enhance ownership utility by offering after-sales services, providing financing options, promoting lifestyle benefits and pride of ownership, and allowing buyers to personalize the product to enhance its appeal.

Operations Management for Manufacturing

Operations Management is a vital component of any business, encompassing the practices, techniques, and tools that organizations use to produce and deliver goods and services efficiently and effectively. Whether in manufacturing or service industries, operations management plays a crucial role in building a competitive edge and driving long-term success.[1] Employing proficient staff, ensuring operations are ethical and safe, and choosing strategic locations are important for maintaining operational excellence.

Operations management and the production process are closely intertwined, as operations management oversees and optimizes the production process to ensure efficiency, quality, and value creation.

Here’s how they relate:

- Planning the Production Process. Operations management involves determining the resources, steps, and timelines needed to produce goods or services. This planning phase aligns production goals with business objectives, ensuring resources like labor, materials, and machinery are used effectively.

- Resource Allocation. The production process requires inputs such as raw materials, labor, and technology. Operations management allocates these resources to minimize waste and optimize productivity, considering costs and demand forecasts.

- Process Optimization. Operations managers analyze the production process to identify bottlenecks, inefficiencies, or areas for improvement. They implement techniques like Lean manufacturing, Six Sigma, or Total Quality Management (TQM) to streamline processes.

- Monitoring and Controlling. During production, operations management monitors progress against planned schedules and budgets. Real-time tracking systems and metrics ensure the process stays aligned with targets, and any deviations are corrected promptly.

- Quality Assurance. Operations management integrates quality control and assurance into the production process to ensure the final products meet customer expectations and regulatory standards.

- Delivery and Feedback. Once production is complete, operations management oversees product delivery, evaluates performance, and collects feedback to refine the process for future cycles.

In summary, operations management is the strategic framework that governs every aspect of the production process, ensuring that goods and services are produced efficiently, meet quality standards, and align with customer and market demands.

Explore the Concept: IKEA’s Operations Model

[IKEA excerpt from Chekhub, Taylor Faircloth, 2021][2]

Operations management is an essential part of the Swedish furniture company IKEA’s success. Its management systems have enabled the company to offer more than 9,500 products at competitive prices as it has grown over nearly eight decades. IKEA’s reputation has rested on its efficient and effective management of:

- Product and process design

- Inventory

- Quality assurance

- Supply chain networks

- Back-end operations

IKEA requires efficient operational management on all levels of the organization, from product design, sourcing materials, and flat packing to distribution and dealing with fluctuations in demand in order to maintain its low prices. Sustaining low manufacturing or service costs through efficient operations management is what sets a successful business apart from the rest.

IKEA has strict requirements on quality, function, and cost when it comes to designing products. To reduce the price of production and distribution, the company uses a ready-to-assemble design for items in its inventory, and the flat packing method used to ship and store its products reduces consumer and manufacturing costs.

IKEA starts each design phase by first setting a price point for a particular product. To reduce waste and overall costs, the company’s standardized production process uses a limited selection of raw materials. From this selection, designers at IKEA create a product that upholds the company standards of affordability, sustainability, quality design, and functionality.

To stay ahead in such a competitive marketplace, IKEA has an extensive forecasting system to predict trends and begin production plans years in advance. The strategic allocation of production based on supplier resources and capacity allows IKEA to balance production volumes across its network of third-party manufacturers. These two factors significantly reduce the cost of production for each unit in its extensive inventory.

After production, IKEA’s operational management oversees the transportation of the final products to a network of 47 automated distribution centers around the globe. The well-designed system ensures cost-effective distribution to the 445 IKEA stores worldwide.

Each retail location functions as both a store and a warehouse. Each location has both an in-store logistics manager and a store goods manager who are responsible for the ordering and material handling processes, respectively. Together, they work to balance customer demand and inventory management while maximizing profits. By merging retail locations with warehouse facilities and a self-service model, IKEA is able to reduce distribution and product storage costs to maintain a competitive edge.

With over 1,800 suppliers around the globe and 43 localized trading offices to maintain relationships with manufacturers, IKEA understands the importance of building strong business relationships through effective communication. To ensure that its inventory will be in stock, IKEA works side-by-side with material suppliers, manufacturers, and factory workers across its supply chain network. IKEA believes that long-term business relationships with suppliers ultimately reduce the cost of goods sold. As a high-volume global retailer, IKEA recognizes that suppliers are meaningful collaborators who add to the business’s value chain. Rather than fostering competition among suppliers, IKEA works directly with suppliers to innovate efficient, low-cost ways to bring its designs to life.

Through tight control over operational efficiencies in the design, production, supply chain, and distribution processes, IKEA has been able to keep consumer and manufacturing costs low while growing the company on a world stage. IKEA perfectly demonstrates the power and significance of operational management systems to elevate a business and optimize its workflows.

Supply Chain

A supply chain refers to the network of individuals, organizations, resources, activities, and technologies involved in the production and distribution of a product or service. It encompasses every stage from sourcing raw materials to delivering the final product or service to the consumer.

Key Components of a Supply Chain:

- Suppliers: Provide the raw materials or components needed for production.

- Manufacturers: Transform raw materials into finished goods.

- Distributors and Wholesalers: Facilitate the movement of goods from manufacturers to retailers.

- Retailers: Sell the final products to consumers.

- Consumers: The end-users of the product or service.

Activities in the Supply Chain:

- Procurement: Sourcing raw materials or goods.

- Production: Converting inputs into finished products.

- Logistics: Transporting and storing goods.

- Demand Planning: Forecasting customer demand to optimize inventory and production.

The goal of an effective supply chain is to deliver products efficiently and cost-effectively while maintaining high levels of quality and customer satisfaction. Supply chain management (SCM) is the monitoring and optimization of the production and distribution of a company’s products and services. It seeks to improve and make more efficient all processes involved in turning raw materials and components into final products and getting them to the ultimate customer. Effective SCM can help streamline a company’s activities to eliminate waste, maximize customer value, and gain a competitive advantage in the marketplace.[3]

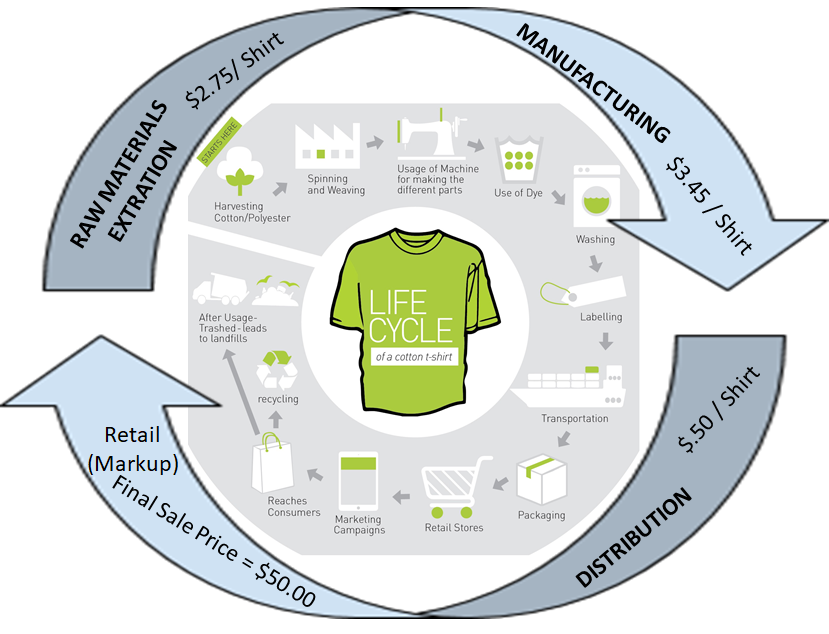

The supply chain and value chain are closely related concepts, but they focus on different aspects of a product’s lifecycle. The key difference lies in their focus:

- The supply chain emphasizes the logistics and operational flow of goods and services from raw materials to the final consumer and the ways in which the process will convert raw materials into goods and services as efficiently as possible (Refer to Figure 9.2, The Lifecycle of a Cotton T-Shirt).

- The value chain focuses on value creation at each step, analyzing how each activity adds value to the product or service and how the costs of operational activities represent a portion of the final sale price of the good or service (Refer to Figure 9.2, The Lifecycle of a Cotton T-Shirt).

Supply chain is often explained as Functional Stages (Planning, Sourcing, Manufacturing (or Production), Distribution, Returns (Reverse Logistics)): Focus on processes within the supply chain, often overlapping with multiple actors; or, as Actor-Based Stages (Supplier, Manufacturer, Distributor, Retailer, Consumer): Focus on who participates in the chain and their responsibilities. Both frameworks are complementary and can be used together to gain a comprehensive understanding of supply chains. The supply chain functions as a continuous loop, with data and insights from one stage influencing decisions in others. This integration ensures efficiency, cost-effectiveness, and customer satisfaction. In essence, the supply chain ensures delivery, while the value chain ensures desirability and worth.

The Gartner Supply Chain Top 25 releases rankings every year, and the 2023 list features a few new logos as well as businesses from years past that have sustained supply chain excellence. The compilation celebrates companies whose supply chain strategies have shown them to be purpose-driven, disruptive, and early adopters of innovative technologies. To recognize the most sustained examples of supply chain excellence, Gartner lists Amazon, Apple, Procter & Gamble, and Unilever as Supply Chain Masters—an accolade earned as a result of having attained top-five composite scores in the Gartner Supply Chain Top 25 for at least seven out of the past 10 years.[4]

You will learn more about supply chain and value chain when you complete an operations management course. This chapter is meant to be an introduction to these concepts.

Circular Economy in Manufacturing

Thecircular economy represents a paradigm shift from the traditional linear model of “take-make-dispose” to a regenerative approach that emphasizes the restoration and regeneration of products, materials, and energy. It challenges conventional metrics of value creation and encourages manufacturers to design products and business models with durability, repairability, and recyclability in mind. Through recycling, part harvesting, remanufacturing, repair, refurbishment, and ecommence, circular economy principles can reduce dependency on scarce resources and component suppliers, building adaptable and resilient supply chains.[5]

For manufacturers, this means ensuring parts and materials within their control never unintentionally exit their sphere of influence. By retaining control over the lifecycle of products, materials and components, manufacturers can prevent resource loss, ensure efficient reuse, enable capitalization of circular practices and reduce their environmental impact.[6] Companies like IKEA focus on product design and production processes that can be easily disassembled or recycled at the end of their life cycle. IKEA’s operations focus on sourcing sustainable materials and creating products that contribute to a circular supply chain. Patagonia has implemented circular supply chain practices by offering repair services for products and encouraging customers to return old items for recycling or resale, contributing to a circular flow of materials.[7]

What fashion consumption habits have been generating in terms of waste is alarming. The global clothing and textile industry is responsible for nearly 100 million metric tons (110,231,131 short tons or 220,462,262,185 pounds!) of waste every year – a figure that could jump by at least 50% by 2030.[8]

Despite the lessons from the digital revolution, many companies continue to focus primarily on refining their existing products and services for their current customer base. But this approach overlooks the transformative potential of the circular economy, which, like the internet in the late 1990s, stands poised to redefine how businesses create, capture and deliver value. As we approach 2030, companies that embrace this shift will lead in innovation and market share, much as early adopters of digital technologies outpaced their peers. The rest of this decade will be crucial for businesses to adapt to this new paradigm, where sustainability is no longer a choice but an essential component of success.[9]

Play the “Creating a Circular Economy for Fashion”, YouTube video below to learn about the innovations in the fashion industry that may just help save our world.[10] Transcript for “Creating a Circular Economy for Fashion” Video [PDF–New Tab]. Closed captioning is available on YouTube.

Operations Managers

Operations managers manage the process that transforms inputs into outputs. Their responsibilities can be grouped as follows:

- Production planning. During production planning, managers determine how goods will be produced, where production will take place, and how manufacturing facilities will be laid out.

- Production control. Once the production process is underway, managers must continually schedule and monitor the activities that make up that process. They must solicit and respond to feedback and make adjustments where needed. At this stage, they also oversee the purchasing of raw materials and the handling of inventories.

- Quality control. The operations manager is directly involved in efforts to ensure that goods are produced according to specifications and that quality standards are maintained.

Let’s take a closer look at each of these responsibilities.

1. Production Planning

The decisions made in the planning stage have long-range implications and are crucial to a firm’s success. Before making decisions about the operations process, managers must consider the goals set by marketing managers. Does the company intend to be a low-cost producer and to compete on the basis of price? Or does it plan to focus on quality and go after the high end of the market? Many decisions involve trade-offs. For example, low cost doesn’t normally go hand in hand with high quality. All functions of the company must be aligned with the overall strategy to ensure success.

Effective production planning requires a thorough analysis of market demand, capacity capabilities, and available resources. It involves aligning production schedules with sales forecasts and considering factors such as lead times, production capacities, and resource availability. Additionally, it involves coordinating with other departments, such as procurement, logistics, and maintenance, to ensure a smooth and uninterrupted production process.[11]

Let’s review the specific types of decisions that have to be made in the production planning process.

Production-Method Decisions

The first step in production planning is deciding which type of production process is best for making the goods that your company intends to manufacture. In reaching this decision, managers should answer such questions as:

- Are we making a one-of-a-kind good based solely on customer specifications, or are we producing high-volume standardized goods to be sold later?

- Do we offer customers the option of “customizing” an otherwise standardized good to meet their specific needs?

One way to appreciate the nature of this decision is by comparing three basic types of processes or methods: make-to-order, mass production, and mass customization. The task of the operations manager is to work with other managers, particularly marketers, to select the process that best serves the needs of the company’s customers.

Make-to-Order (MTO)

At one time, most consumer goods, such as furniture and clothing, were made by individuals practicing various crafts. By their very nature, products were customized to meet the needs of the buyers who ordered them. This process, which is called a make-to-order strategy, is still commonly used by such businesses as print or sign shops that produce low-volume, high-variety goods according to customer specifications. This level of customization often results in a longer production and delivery cycle than other approaches. It is suitable for niche markets or high-value goods (e.g., luxury yachts or custom furniture).

The advantages of make-to-order production include a lower likelihood of unsold inventory, easily adapts to specific customer requirements, and manufacturing products only after receiving customer orders.

The disadvantages of make-to-order production include higher costs due to smaller production runs and customized processes, can lead to idle production capacity if orders are low, and customers must wait for products to be made.

Mass Production

By the early twentieth century, a new concept of producing goods had been introduced: mass production (or make-to-stock strategy), the practice of producing high volumes of identical goods at a cost low enough to price them for large numbers of customers. Goods are made in anticipation of future demand (based on forecasts) and kept in inventory for later sale. This approach is particularly appropriate for standardized goods ranging from processed foods to electronic appliances. It generally results in shorter cycle times than a make-to-order process. This type of production also takes advantage of economies of scale, which refers to the reduced costs per unit that are realized from an increased total number of units produced. It is best for high-demand products (e.g., Coca-Cola or generic clothing).

The advantages of mass production include lower per-unit costs due to economies of scale, high production rates that meet large market demand quickly, and uniform quality of products due to standardized processes.

The disadvantages of mass production include limited ability to adapt to changing customer preferences, requiring substantial capital for machinery and setup, and overproduction may lead to surplus stock and storage costs.

Mass Customization

There is at least one big disadvantage to mass production: customers, as one old advertising slogan put it, can’t “have it their way.” They have to accept standardized products as they come off assembly lines. Increasingly, however, customers are looking for products that are designed to accommodate individual tastes or needs but can still be bought at reasonable prices. To meet the demands of these consumers, many companies have turned to an approach called mass customization, which combines the advantages of customized products with those of mass production.

This approach requires that a company interact with the customer to find out exactly what the customer wants and then manufacture the goods, using efficient production methods to hold down costs. One efficient method is to mass-produce a product up to a certain cut-off point and then to customize it to satisfy different customers. It is ideal for industries offering personalized products (e.g., Dell’s customizable computers).

The advantages of mass customization include offering personalized products that enhance customer loyalty, helping businesses stand out in markets filled with standardized goods, and leveraging automation and modular design for greater adaptability.

The disadvantages of mass customization include generally higher unit costs compared to traditional mass production, the need for advanced technology and logistics to handle customization efficiently, and the potential for slower production speeds due to the customization process.

One of the best-known mass customizers is Nike, which has achieved success by allowing customers to configure their own athletic shoes, apparel, and equipment through “Nike By You” program. The Web has a lot to do with the growth of mass customization. Levi’s, for instance, lets customers find a pair of perfectly fitting jeans, then helps them personalize the jeans through the “Levi’s Tailor Shop“. Oakley offers customized sunglasses, goggles, watches, and backpacks. Mars, Inc. can make M&M’s in any color the customer wants (say, school colours) as well as add text and even pictures to the candy.

Naturally, mass customization doesn’t work for all types of goods. Most people don’t care about customized detergents or paper products. And while many of us like the idea of customized clothes, footwear, or sunglasses, we often aren’t willing to pay the higher prices they command.

Refer to Table 9.1 for a comparison of features for mass production, mass customization, and make-to-order production methods.

| Feature | Mass Production | Mass Customization | Make-to-Order |

|---|---|---|---|

| Customer Focus | Low | High | Very High |

| Cost Efficiency | Very High | Moderate | Low |

| Flexibility | Low | Moderate to High | Very High |

| Lead Times | Short | Moderate | Long |

| Production Risk | Inventory Surplus | Moderate (requires demand prediction) | Low (no overproduction) |

Facilities Decisions

After selecting the best production process, operations managers must then decide where the goods will be manufactured, how large the manufacturing facilities will be, and how those facilities will be laid out.

Site Selection

Site selection involves measuring the needs of a new project against the merits of potential locations. In site selection, managers must consider several factors:

- To minimize shipping costs, managers often want to locate plants close to suppliers, customers, or both.

- They generally want to locate in areas with ample numbers of skilled workers.

- They naturally prefer locations where they and their families will enjoy living.

- They want locations where costs for resources and other expenses—land, labour, construction, utilities, and taxes—are low.

- They look for locations with a favourable business climate—one in which, for example, local governments might offer financial incentives (such as tax breaks) to entice them to do business in their locales. For example, an enterprise zone is an area in which incentives are used to attract investments from private companies.

Managers rarely find locations that meet all these criteria. As a rule, they identify the more important criteria and aim to satisfy them. For example, Toyota Manufacturing Canada (TMMC) established one of its assembly plants in Cambridge, Ontario, after an extensive site selection process. Factors that influenced the site selection decision included skilled workforce, proximity to automotive supply chains, access to major markets (close to U.S. border), transportation infrastructure (major highways and railways), government incentives (Canadian and Ontario governments provided financial incentives and tax breaks), cost of operations (affordable), and cultural fit (high-quality manufacturing and workforce reliability aligned with Toyota’s brand image and production standards).

Facility Layout

The facility layout is the physical arrangement of resources. The facility layout should be planned to handle materials orderly and efficiently and ensure a smooth flow of production. For instance, the distance that a work-in-progress must travel within a facility should be considered. Different manufacturing processes require different facility layouts.

The four main types of facility layouts are:

-

Process layout: Groups similar machines or functions together. Best for low-volume, varied products. Example: Hospital departments.

-

Product layout: Arranges equipment in sequence for mass production of identical items. Example: Car assembly line.

-

Fixed-position layout: The product stays in one place while workers and tools move to it. Example: Shipbuilding.

-

Cellular layout: Machines are grouped into cells to produce related product families efficiently. Example: Computer parts manufacturing.

A company may also choose to combine any of these layouts into a hybrid layout.

Capacity Planning

Now that the company has determined a location, the next decision is on the quantity of products that will be produced. Managers begin by forecasting demand for the company’s product, which isn’t easy. To estimate the number of units that is likely to sell over a given period, they have to understand the industry that they are in and estimate their likely share of the market by reviewing industry data and conducting other forms of research.

Once demand for the product has been forecasted, managers can calculate the capacity requirements of the production facility—the maximum number of goods that it can produce over a given time under normal working conditions. In turn, having calculated the capacity requirements, they are ready to determine how much investment in the plant and equipment they will have to make, as well as the number of labour hours required for the plant to produce at capacity and meet demand.

Like forecasting, capacity planning can be challenging. However, failing to align capacity with expected demand can significantly impact a company’s profitability. If capacity is too low, the business may fall short of meeting demand, resulting in lost sales and customers. On the other hand, if capacity is too high and production exceeds demand, resources are wasted and operating costs rise. That’s why continuous review—the ongoing evaluation of organizational processes to identify opportunities for increased efficiency—is a critical part of capacity planning. It helps ensure that production levels stay in line with actual demand.

2. Production Control

Production control is a crucial function in operations management that ensures resources are used efficiently and effectively to meet production goals. It integrates purchasing, inventory control, and work scheduling to streamline production processes.

Purchasing

The process of acquiring the materials and services to be used in production is called purchasing (or procurement). For many products, the costs of materials make up about 50 percent of total manufacturing costs. Not surprisingly, materials acquisition gets a good deal of the operations manager’s time and attention.

Supplier Selection

Supplier selection is a critical aspect of purchasing. It involves choosing the best vendors to meet the company’s material or service requirements based on specific criteria. As a rule, there’s no shortage of vendors willing to supply materials, but the trick is finding the best suppliers. Operations managers must consider the following:

- Can the vendor supply the needed quantity of materials at a reasonable price?

- Is the quality good?

- Is the vendor reliable (will materials be delivered on time)?

- Does the vendor have a favourable reputation?

- Is the company easy to work with?

Use key performance indicators (KPIs) to assess potential vendors:

- Cost: Are the prices competitive?

- Quality: Do they meet the required standards consistently?

- Reliability: Are deliveries made on time?

- Capacity: Can they handle the required volume?

- Sustainability: Do they align with the company’s ethical and environmental goals?

Importance of Strategic Supplier Selection:

- Cost Efficiency: Reducing production costs through competitive pricing.

- Quality Assurance: Ensuring final products meet customer expectations.

- Risk Mitigation: Reducing supply chain disruptions by working with reliable suppliers.

- Innovation: Collaborating with suppliers who offer advanced technologies or innovative solutions.

In summary, the integration of efficient purchasing and careful supplier selection can significantly enhance a company’s operational performance and competitive advantage.

Procurement

Technology has changed the way businesses buy things. Through modern procurement, companies use the Internet to interact with suppliers. The process is similar to the one you’d use to find a consumer good—say, a high-definition TV—over the Internet. To choose a TV, you might browse the websites of manufacturers like Sony, then shop for prices and buy on Amazon, the world’s largest online retailer.

If you were a purchasing manager using the Internet to buy parts and supplies, you’d follow the same process. You’d identify potential suppliers by going directly to private websites maintained by individual suppliers or to public sites that aggregate information on numerous suppliers. You could do your shopping through online catalogs, or you might participate in an online marketplace by indicating the type and quantity of materials you need and letting suppliers bid. Finally, just as you paid for your TV electronically, you could use a system called electronic data interchange (EDI) to process your transactions and transmit all your purchasing documents.

The Internet provides an additional benefit to purchasing managers by helping them communicate with suppliers and potential suppliers. They can use the Internet to give suppliers specifications for parts and supplies, encourage them to bid on future materials needs, alert them to changes in requirements, and give them instructions on doing business with their employers. Using the Internet for business purchasing cuts the costs of purchased products and saves administrative costs related to transactions. It’s also faster for procurement and fosters better communications.

Harley-Davidson maintains a Supplier Diversity policy for making decisions in this area of operations management. This decision area is concerned with optimizing the supply chain for the motorcycle manufacturer’s growth. The company’s policy ensures the optimal productivity and capacity of its supply chain based on the availability of a wide variety of suppliers. Success in this area of operations management depends on how policies and strategies address the bargaining power of suppliers described in the Five Forces analysis of Harley-Davidson. Also, decisions in supply chain management account for supply-related industry and market conditions, such as the trends shown in the PESTLE/PESTEL analysis of Harley-Davidson.[12]

Outsourcing in the Manufacturing Sector

Outsourcing in business refers to the practice of contracting out certain business functions, tasks, or processes to external vendors or service providers, rather than handling them in-house. This strategy is commonly employed by companies to reduce costs, gain access to specialized expertise, or increase efficiency by leveraging external resources. These tasks can include activities such as customer service, manufacturing, IT support, human resources, and more. A company may decide to outsource manufacturing to a foreign country where labor costs are lower, influencing both the location of operations and the logistics required to maintain supply chains. For example, Nike has been known for outsourcing the majority of its manufacturing, choosing to locate production in countries like Vietnam, China, and Indonesia. This allows Nike to focus on its product design and marketing while relying on external partners for labor-intensive tasks. This outsourcing model significantly impacts both its product/service strategy and supply chain decisions.

Some reasons companies outsource include:

- Companies might outsource to reduce costs

- Gain access to expertise, technology, and innovation that they currently do not have

- To better focus on core business activities by outsourcing non-core activities

- Outsourcing provides flexibility in scaling operations up or down quickly.

- Companies can reduce risks by sharing risks with, or transferring some risks to, external partners

- For global companies, outsourcing to different time zones can provide a 24-hour work cycle

While outsourcing provides numerous advantages, it also has some disadvantages, including:

- Ensuring quality standards are met

- Maintaining control over outsourced functions

- Risks of data breaches or the mishandling of sensitive information

- Communication issues, such as language barriers or cultural differences

- Limited options to switch providers without incurring costs or disruptions

- Vulnerability if the company over-relies on the partner and the partner fails to deliver

- Risks of intellectual property theft or misuse by third-party providers

Outsourcing has become an increasingly popular option among manufacturers. For one thing, few companies have either the expertise or the inclination to produce everything needed to make a product. Today, more firms want to specialize in the processes that they perform best (core function) and outsource the rest. Companies also want to take advantage of outsourcing by linking up with suppliers located in regions with lower labour costs. Outsourcing can be local, regional, or even international, and companies can outsource everything from parts for their products, like automobile manufacturers do, to complete manufacturing of their products, like Nike and Apple do. Apple outsources the production of certain components (like chips or displays) to specialized manufacturers, enhancing both product quality and innovation.

Inventory Control

If a manufacturer runs out of the materials it needs for production, then production stops. In the past, many companies guarded against this possibility by keeping large inventories of materials on hand. It seemed like the thing to do at the time, but it often introduced a new problem—wasting money. Companies were paying for parts and other materials that they wouldn’t use for weeks or even months, and in the meantime, they were running up substantial storage and insurance costs. If the company redesigned its products, some parts might become obsolete before ever being used.

Most manufacturers have since learned that to remain competitive, they need to manage inventories more efficiently. This task requires that they strike a balance between two threats to productivity: losing production time because they’ve run out of materials and wasting money because they’re carrying too much inventory. The process of striking this balance is called inventory control, and companies now regularly rely on a variety of inventory-control methods.

Just-in-Time Production

One method is called just-in-time (JIT) production: the manufacturer arranges for materials to arrive at production facilities just in time to enter the manufacturing process. Parts and materials don’t sit unused for long periods, and the costs of “holding” inventory are significantly cut. JIT, however, requires considerable communication and cooperation between the manufacturer and the supplier. The manufacturer has to know what it needs and when. The supplier has to commit to supplying the right materials, of the right quality, at exactly the right time. An example in retail: A grocery store uses JIT systems to replenish stock based on sales data from its point-of-sale system, reducing waste of perishable items.

Material Requirements Planning

A software tool called material requirements planning (MRP), relies on sales forecasts and ordering lead times for materials to calculate the quantity of each component part needed for production and then determine when they should be ordered or made. The detailed sales forecast is turned into a master production schedule (MPS), which MRP then expands into a forecast for the needed parts based on the bill of materials for each item in the forecast. A bill of materials is simply a list of the various parts that make up the end product. The role of MRP is to determine the anticipated need for each part based on the sales forecast and to place orders so that everything arrives just in time for production.

Inventory Management Software

Tools like SAP, Oracle NetSuite, or QuickBooks help automate inventory tracking and analysis. An example in the manufacturing sector, a car manufacturer that maintains a safety stock of critical components to avoid production halts due to supply chain disruptions. An example in the manufacturing sector: A car manufacturer maintains a safety stock of critical components to avoid production halts due to supply chain disruptions. Point-of-sale (POS) systems track everything sold during a given time and provide information on how much of each item should be kept in inventory.

Work Scheduling

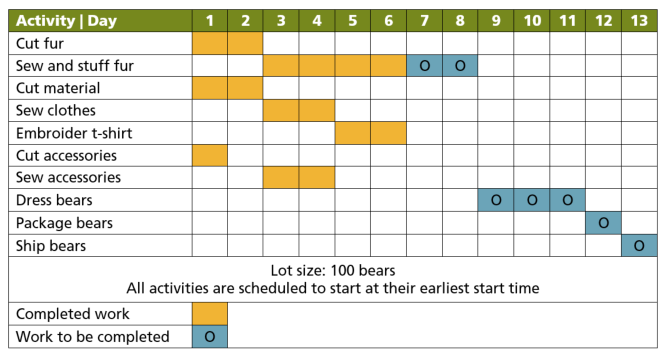

To control the timing of all operations, managers set up schedules: they select jobs to be performed during the production process, assign tasks to work groups, set timetables for the completion of tasks, and make sure that resources will be available when and where they’re needed. There are a number of scheduling techniques. We’ll focus on two of the most common graphical tools—Gantt and PERT charts.

Gantt Charts

A Gantt chart—named after its creator, Henry Gantt—is an easy-to-read graphical tool that helps operations managers track the progress of a project. For example, Figure 9.3 shows a Gantt chart for producing one hundred “hiker” bears at the Toronto Teddy Bear Company. The chart indicates that several activities must be completed before the bears can be dressed: the fur must be cut, sewn, and stuffed, and the clothing and accessories must be produced. By day six, all accessories and clothing are finished, but sewing and stuffing (both required before dressing can begin) are not scheduled for completion until the end of day eight. As the operations manager, you would need to closely monitor sewing and stuffing to ensure the bears are completed on time.

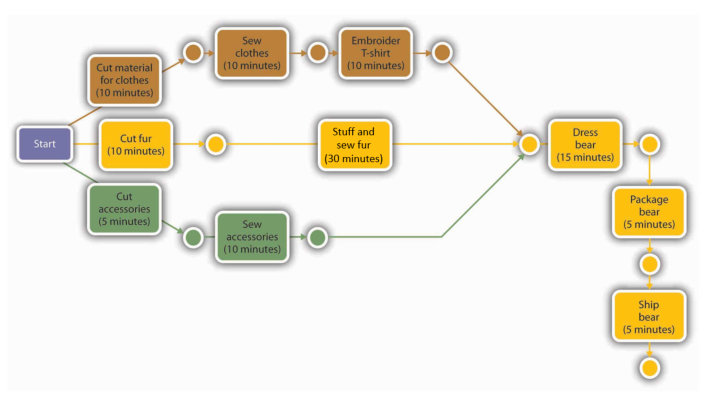

PERT Charts

Gantt charts work well for straightforward processes with limited task dependency. For more complex operations, managers often rely on PERT (Program Evaluation and Review Technique). PERT charts map all activities required to produce a product, estimate the time required for each step, and determine the most efficient task sequence.

A key advantage of PERT is its ability to identify the critical path—the sequence of activities that determines the minimum time needed to complete the entire project. Any delay in a critical-path activity delays the entire process, and total production time can be reduced only by shortening tasks on this path.

Figure 9.4 provides a PERT diagram for making one “hiker” bear. Production begins at the cutting station. The cut fur then moves through sewing and stuffing before reaching the dressing station. Meanwhile, the bear’s clothing is cut and sewn, the T-shirt is embroidered, and the backpack and tent accessories are produced. All components meet at the dressing station, where the bear is outfitted, then packaged and shipped.

In this example, the critical path is the longest sequence of activities—cutting → stuffing → dressing → packaging → shipping—a process that takes sixty-five minutes. Even if clothing or accessories are completed sooner, they must wait for the fur to move through sewing, stuffing, and dressing. Thus, overall efficiency can be improved only by shortening tasks on the critical path.

The Critical Path

The critical path identifies the set of tasks that must occur in a specific sequence to complete a project in the shortest possible time. It reflects task dependencies—some activities must be completed before others can begin. A critical path diagram helps managers schedule these dependencies and monitor project progress. To determine the critical path, the expected duration of each activity must first be calculated.

The concept of the critical path is central to PERT. PERT is specifically designed to analyze task relationships, calculate activity durations, and highlight the sequence of activities that determines the minimum time needed to complete the entire project.

Gantt charts, on the other hand, primarily display task timing. While basic Gantt charts do not automatically show the critical path, many modern project-management tools (such as MS Project or Smartsheet) can overlay critical path information onto a Gantt chart, allowing managers to see which tasks determine the project’s overall duration.

3. Quality Control

Quality is defined by the International Standards Organization (ISO) as the degree to which a set of inherent characteristics of an object fulfills requirements.[13] The term “Quality” can be subjective and can vary depending on the context, the perspective, and the criteria used to evaluate it.

What do you do if your brand-new phone doesn’t work when you get it home? Like most people, you’d probably be more or less disgruntled. As a customer, you’re constantly assured that when products make it to market, they’re of the highest possible quality, and you tend to avoid brands that have failed to live up to your expectations or to producers’ claims. When you buy a mobile phone, you expect it to be able to easily connect and communicate. If your expectations are not met, you’ll conclude that you’re the victim of poor quality.

Quality Control in Manufacturing is the process of ensuring that products meet predefined quality standards and specifications, helping to deliver consistent and reliable outputs. It involves systematic planning, implementation, and evaluation of processes to maintain product quality.

Key aspects of quality control include:

- Inspection and testing

- Process monitoring (Statistical Process Control (SPC))

- Standardization (ISO 9001)

- Defect prevention (Six Sigma)

Here are some examples of quality control in practice:

- Automotive: Toyota employs the Andon system, which allows production to be halted instantly when a quality issue is identified, combining lean manufacturing principles with strict quality control.[14]

- Electronics: Apple conducts extensive quality testing, including assessments of material durability and product performance, before releasing products to the market.[15]

Total Quality Management (TQM)

Total quality management (TQM) is the continual process of detecting and reducing or eliminating errors in manufacturing. It streamlines supply chain management, improves the customer experience, and ensures that employees are up to speed with training.[16]

A Quality Management System (QMS) is a formalized system that documents processes, procedures, and responsibilities for achieving quality policies and objectives. The QMS helps manufacturing companies coordinate and direct activities to meet customer and regulatory requirements.[17]

The TQM strategy requires consistent feedback from employees and customers to determine how services and products can be improved across the organization and is designed to help companies find a path to strengthen their position in the market, increase productivity, improve customer loyalty and satisfaction, boost employee morale, and improve processes. Whereas many quality management strategies focus on specific departments, TQM includes every department in continually improving a company’s products and services. According to the TQM philosophy, the more you improve processes in every department, the easier it will be to deliver higher-quality products and services to customers. With TQM, everyone in the company should be focused on quality improvement with the shared goal of boosting customer loyalty and satisfaction. [18]

Total quality management (TQM), or quality assurance, includes all the steps that a company takes to ensure that its goods or services are of sufficiently high quality to meet customers’ needs. Generally speaking, a company adheres to TQM principles by focusing on three tasks: Customer satisfaction, employee involvement, and continuous improvement. Let’s take a closer look at these three principles.

Customer Satisfaction

Companies that are committed to TQM understand that the purpose of a business is to generate a profit through customer satisfaction. Thus, they let their customers define quality by identifying desirable product features and then offering them. They encourage customers to tell them how to offer services that work the right way. Armed with this knowledge, they take steps to make sure that providing quality is a factor in every facet of their operations—from design to product planning and control, to sales and service. To get feedback on how well they’re doing, many companies routinely use surveys and other methods to monitor customer satisfaction. By tracking the results of feedback over time, they can see where they need to improve.

Employee Involvement

Successful TQM requires that everyone in the organization, not simply upper-level management, commits to satisfying the customer. A mobile phone isn’t solely the responsibility of the manufacturer’s quality control department; it’s the responsibility of every employee involved in its design, production, and even shipping. To get everyone involved in the drive for quality assurance, managers must communicate the importance of quality to subordinates and motivate them to focus on customer satisfaction. Employees have to be properly trained not only to do their jobs but also to detect and correct quality problems. In many companies, employees who perform similar jobs work as teams, sometimes called quality circles, to identify quality, efficiency, and other work-related problems, to propose solutions, and to work with management in implementing their recommendations.

Continuous Improvement

An integral part of TQM is continuous improvement: the commitment to making constant improvements in the design, production, and delivery of goods and services. Improvements can almost always be made to increase efficiency, reduce costs, and improve customer service and satisfaction. Everyone in the organization is constantly on the lookout for ways to do things better.

Statistical Process Control

Statistical process control (SPC) is defined as the use of statistical techniques to control a process or production method. SPC tools and procedures can help you monitor process behavior, discover issues in internal systems, and find solutions for production issues. Statistical process control is often used interchangeably with statistical quality control (SQC).[19]

Companies can use a variety of tools to identify areas for improvement. A common approach in manufacturing is called statistical process control. This technique monitors production quality by testing a sample of output to see whether goods in process are being made according to predetermined specifications. An example of a statistical process control method is Six Sigma. A Six-Sigma process is one in which 99.99966% of all opportunities to perform an operation are free of defects. This percentage equates to only 3.4 defects per million opportunities.

Assume for a moment that you work for Kellogg’s, the maker of Raisin Bran cereal. You know that it’s the company’s goal to pack two scoops of raisins in every box of cereal. How can you test to determine whether this goal is being met? You could use a statistical process control method called a sampling distribution. On a periodic basis, you would take a box of cereal off the production line and measure the amount of raisins in the box. Then you’d record that amount on a control chart designed to compare actual quantities of raisins with the desired quantity (two scoops). If your chart shows that several samples in a row are low on raisins, you’d take corrective action.

SPC is widely used in manufacturing industries to monitor and control production processes. By using tools like control charts, histograms, and Pareto charts, manufacturers can identify variations in processes, detect defects early, and improve product quality. This method is particularly effective in industries like automotive, electronics, food production, and pharmaceuticals.

Production Process Technologies

Computer-aided design (CAD) and computer-aided manufacturing (CAM) are technologies that work together and are widely used across various industries to improve design, manufacturing, and production processes. These technologies represent the evolution of manufacturing from manual processes to fully automated and integrated systems, resulting in higher productivity and better-quality products.

Computer-Aided Design

CAD refers to the use of computer software to create, modify, analyze, or optimize a design. CAD is widely used in engineering, architecture, and product design to develop precise technical drawings and 3D models. It allows users to detail 2D and 3D models of products, parts, or structures and can test and simulate these designs under various conditions before manufacturing. Examples of CAD software include AutoCAD, SolidWorks, and CATIA. When engineers design a car part (e.g., a wheel rim) using 3D modeling software.

In an automotive company, CAD is when an engineer designs a car part (e.g., a wheel rim) using 3D modeling software.

Computer-Aided Manufacturing

CAM refers to the use of computer software and hardware to control and automate manufacturing processes. CAM takes CAD designs and converts them into instructions for machines, such as CNC (Computer Numerical Control) equipment. Examples of CAM software include Mastercam, Fusion 360, and Siemens NX.

Because CAD and CAM programs can “talk” with each other, companies can build components that satisfy exactly the requirements set by the computer-generated model. CAD/CAM systems permit companies to design and manufacture goods faster, more efficiently, and at a lower cost, and they’re also effective in helping firms monitor and improve quality. CAD/CAM technology is used in many industries, including the auto industry, electronics, and clothing. If you have ever seen how a 3-D printer works, you have a pretty good idea of how CAM works too.

In an automotive company, CAM is when the design is sent to a CNC machine, which uses the instructions to precisely cut the wheel rim from a metal block.

Computer-Integrated Manufacturing

CIM represents a comprehensive approach to manufacturing where CAD, CAM, and other business and manufacturing processes are integrated using computer systems. It enables seamless communication between design, production, and management. Examples of CIM systems include ERPs such as SAP and Oracle NetSuite, and robotics and automated assembly lines.

CIM systems expand the capabilities of CAD/CAM. In addition to design and production applications, they handle such functions as order entry, inventory control, warehousing, and shipping. In the manufacturing plant, the CIM system controls the functions of industrial robots—computer-controlled machines used to perform repetitive tasks that are also hard or dangerous for human workers to perform.

In an automotive company, CIM is when the entire manufacturing process is integrated with inventory, quality control, and supply chain systems to ensure the right materials are available, defects are minimized, and production schedules are met.

Enterprise Resource Planning (ERP)

Material Requirements Planning (MRP) and Enterprise Resource Planning (ERP) are interconnected systems used in modern business operations, particularly in manufacturing and supply chain management. While they serve different purposes, they are closely related and often integrated for greater efficiency. MRP is a system focused on managing the materials and components required for production. It ensures that the right materials are available at the right time to meet production schedules. Key functions include inventory control, production planning, and scheduling materials procurement. ERP is a broader, integrated system that manages and automates a company’s core business processes across multiple departments, including finance, HR, manufacturing, supply chain, sales, and customer relationship management (CRM). It often incorporates MRP as a module.

To keep up with ever-changing customer demand and rising costs, manufacturers are always looking for ways to improve operations, boost efficiency, and stay competitive. But traditional methods for maintaining that competitive edge may no longer be enough in today’s world of complex global supply chains and economic uncertainty. According to Deloitte’s “2022 Manufacturing Supply Chain Study,” 76% of the over 200 manufacturing executives surveyed listed investing in digital supply chain tools as a top strategy to overcome challenges that can include shipping delays and material shortages.[20]

The use of ERP in manufacturing companies provides several benefits: integration of centralization, data-driven decision-making, and connectivity and communication internally (all departments, locations) and externally (customers, suppliers). There are ERP systems available for manufacturing and service businesses.

An enterprise resource planning (ERP) system is a comprehensive business platform that helps businesses manage their daily operations. Manufacturing ERP systems are specifically designed for the manufacturing industry and include specialized features to address the industry’s unique challenges, such as production planning, inventory management, quality control, and order tracking. These systems centralize and streamline manufacturing operations by collecting, analyzing, and reporting on business-wide data. Stakeholders can use this data — often through the use of automation and advanced analytics tools — to improve efficiency, increase productivity, and reduce costs. Manufacturers can also leverage this ERP technology to increase visibility into the entire manufacturing process to impart resilience and potentially improve profitability on the whole.[21]

Key features of manufacturing ERP systems include:[22]

- Inventory management

- Sales order management

- Quality management

- CAD/CAM management

- Bill of Materials (BOM) management

- Planning and scheduling

- Mobile capabilities

Benefits of manufacturing ERP systems include:[23]

- Optimized stock levels

- Reduced carrying charges

- Reduced stock shortage or stock surplus situations

- Improved delivery times

- Reduced order errors

Operations Management for Service Providers

Operations management in service companies and manufacturing companies differs significantly due to the nature of their outputs, processes, and customer interaction.

Though the primary function of both manufacturers and service providers is to satisfy customer needs, there are several important differences between the two types of operations. Let’s focus on three of them:

- Intangibility. Manufacturers produce tangible products—things that can be touched or handled, such as automobiles and appliances. Service companies provide intangible products, such as banking, entertainment, or education.

- Customization. Most manufactured goods are standardized. Services, by contrast, are often customized to satisfy the specific needs of a customer. For example, when you go to the hairdresser, you ask for a haircut that looks good on you because of the shape of your face and the texture of your hair.

- Customer contact. You could spend your entire working life assembling cars in Detroit and never meet a customer who bought a car that you helped to make. But if you were a restaurant server, you’d interact with customers every day. In fact, their satisfaction with your product would be determined in part by the service that you provided. Unlike manufactured goods, many services are bought and consumed at the same time.

As the Canadian economy has changed from a goods producer to a service provider over the last sixty years, the dominance of the manufacturing sector has declined substantially. Today, only about 10 percent of Canadian workers are employed in manufacturing, in contrast to 30 percent in 1950. Research highlights manufacturing’s steady decline relative to the growing service sector, with automation and international trade reshaping the industry.[24] Most of us now hold jobs in the service sector, which accounts for approximately 80 percent of Canadian jobs.[25]

In service firms, managers typically organize their responsibilities into three key areas: planning operations, managing operations, and controlling quality. These areas help ensure the firm operates effectively and efficiently while meeting customer expectations. Let’s review these below.

1. Operations Planning

Service organizations must carefully design their services to meet customer needs while ensuring efficiency. This involves selecting the right service model (e.g., self-service, direct service, or hybrid) and determining the layout of service processes to streamline operations and reduce wait times. For example, in a restaurant, the kitchen layout must optimize food preparation time while ensuring smooth customer service.

When starting or expanding operations, businesses in the service sector must make a number of decisions quite similar to those made by manufacturers:

- What services (and perhaps what goods) should they offer?

- Where will they locate their business, and what will their facilities look like?

- How will they forecast demand for their services?

Let’s see how service firms answer questions such as these.

Operations Processes

When planning operations, service organizations focus on tailoring their operations processes to deliver high-quality and consistent service experiences.

Service organizations succeed by providing services that satisfy customers’ needs. Companies that provide transportation, such as airlines, have to get customers to their destinations as quickly and safely as possible. Companies that deliver packages, such as FedEx, must pick up, sort, and deliver packages in a timely manner. Companies that provide both services and goods, such as Domino’s Pizza, have a dual challenge: they must produce a quality good and deliver it satisfactorily.

Service providers that produce goods can adopt either a make-to-order or a make-to-stock approach to producing them. Subway encourages patrons to customize their sandwiches by using a make-to-order approach, building sandwiches one at a time. Although many fast food restaurants have adopted the make-to-order model, a few continue to make-to-stock. For example, Dunkin’ Donuts does not customize doughnuts, and so they do not have to wait for customer orders before making them.

Like manufacturers, service providers must continuously look for ways to improve operational efficiency.

Explore the Concept: McDonald’s Removing Self-Serve Soda Stations

Several years ago, many fast-food restaurants moved the drink stations from behind the counter so that customers could take over the time-consuming task of filling cups with ice and beverages. This allowed the restaurants to cut back on the number of employees needed per day at every location.

In 2024, McDonald’s decided to eliminate self-serve drink stations from its U.S. locations by 2032. The decision isn’t merely about drinks–it reflects a fundamental shift in how customers interact with restaurants today. Digital sales now represent 40% of McDonald’s total revenue, highlighting a dramatic shift toward drive-thru and delivery services. With fewer customers dining in, maintaining large self-serve drink stations has become increasingly impractical. This transformation aligns with McDonald’s vision for future restaurant designs, which may feature smaller dining areas or none at all. New automated beverage systems will mechanically fill drink orders, ensuring consistency across all ordering channels. This standardization means that whether you’re ordering through the app, drive-thru, or in person, your drinking experience remains identical. Beyond adapting to changing consumer habits, this shift brings several operational advantages. The removal of self-serve stations helps maintain cleaner dining areas and reduces maintenance requirements. The transition period until 2032 allows franchisees ample time to adapt their operations and implement new systems gradually. This methodical approach ensures minimal disruption to daily operations while maintaining customer satisfaction.[26]

This shift represents part of a broader industry trend. Other major chains like Chick-fil-A and Taco Bell are also experimenting with new service models that emphasize efficiency and automation. These changes reflect an industry-wide movement toward more streamlined operations that better serve modern consumer preferences.[27]

Facilities

When starting or expanding a service business, owners and managers must invest a lot of time in selecting a location, determining its size and layout, and forecasting demand. A poor location or a badly designed facility can deter customers, and inaccurate estimates of demand for products can result in poor service, excessive costs, or both.

Site Selection

Site selection is also critical in the service industry, but not for the same reasons as in the manufacturing industry. Service businesses need to be accessible to customers. Some service businesses, such as cable-TV providers, package-delivery services, and e-retailers, go to their customers. Many others, however—hotels, restaurants, stores, hospitals, and airports—have to attract customers to their facilities. These businesses must locate where there’s a high volume of available customers. In picking a location, service companies perform a detailed analysis of demographics and traffic patterns; the number of people that pass by a specific location in the course of a day. In Canada, where we travel almost everywhere by car, it would make sense for service businesses to look for busy intersections, highway interchanges with easy off and on ramps, or such “primary destinations” as shopping malls, tourist attractions, downtown business areas, or movie theaters. In Europe, public transportation service firms might focus on subway, train, bus, and trolley stops.

Once planners find a site with an acceptable traffic count, they apply other criteria. It must, for example, be easy for vehicles to enter and exit the site, which must also provide enough parking to handle projected dine-in business. Local zoning must permit standard signage, especially along major highways. Finally, expected business must be high enough to justify the cost of the land and building, and future projections of economic growth (expansion) should be positive.

Size and Layout

In the service sector, most businesses must design their facilities with the customer in mind: they must accommodate the needs of their customers while keeping costs as low as possible. It may be more convenient for a hospital to place its freight elevators in the center of the building, for example, but doing so may block the flow of patients, visitors, and medical personnel between floors and departments. The layout of a fast-food restaurant can help the employees involved in different parts of the process–preparing the food and serving customers–to work in a more integrated fashion. For example, the placement of prepared orders, ready for packaging, is near the front counter and drive-thru staff, to make it easier for these staff to pick up the order, put it in a bag or on a tray, and deliver it to the customer.

Service organizations often design operations to adapt quickly to changing demands. For example, a call center may scale its workforce during promotions or crisis situations.

As mentioned previously, there are four main types of facility layouts: process, product, fixed-position, and cellular. A company may also choose to combine any of these layouts into a hybrid layout. To learn more about each type, refer to the end-of-chapter exercises and complete the Service Facility Layout exercise.

Capacity Planning

Estimating capacity needs for a service business isn’t the same thing as estimating those of a manufacturer. Service providers can’t store their products for later use: hairdressers can’t “inventory” haircuts, and amusement parks can’t “inventory” roller-coaster rides. Service firms have to build sufficient capacity to satisfy customers’ needs on an “as-demanded” basis. Like manufacturers, service providers must consider many variables when estimating demand and capacity:

- How many customers will we have?

- When will they want our services (which days of the week, which times of the day)?

- How long will it take to serve each customer?

- How will external factors, such as weather or holidays, affect the demand for my services?

Since services are often produced and consumed simultaneously, capacity planning is crucial. Service managers need to ensure that there is adequate staffing, equipment, and space to meet customer demand without overburdening employees or creating excess capacity. For instance, call centers may adjust staffing based on forecasted call volumes.

Forecasting demand is easier for companies that have a long history of planning facilities than for brand-new service businesses. Existing companies can predict sales for a new restaurant by combining its knowledge of customer-service patterns at existing restaurants with information collected about each new location, including the number of cars or people passing the proposed site and the effect of nearby competition.

2. Operations Control

Overseeing a service organization puts special demands on managers, especially those running firms, such as hotels, retail stores, and restaurants, who have a high degree of contact with customers. Service firms provide customers with personal attention and must satisfy their needs in a timely manner. This task is complicated by the fact that demand can vary greatly over the course of any given day. Managers, therefore, must pay particular attention to employee work schedules and, in many cases, inventory management.

Managing service operations is about more than the efficiency of service. It is about finding a balance between profitability, innovation, customer satisfaction, and associate satisfaction, sometimes referred to as the balanced scorecard. The balanced scorecard model utilizes 360-degree feedback, a process of collecting feedback from all of a business’s stakeholders, in order to improve operational efficiency.

Customer Experience

Moment of Truth marketing refers to the type of marketing that takes place at the moment when a customer interacts with a product, brand, or service, and forms or changes their impression about it. Moments can range from calling a help line, checking in at an airline counter, the greeting from a hostess in a restaurant, to having a maintenance problem resolved in a hotel guest room. The quality of staff a company hires, how they train their employees, and the focus management places on creating a culture of service will determine how successful the company is in service delivery and maximizing the impact of these moments of truth. Employee performance directly impacts service delivery, so effective training and engagement are key. Service organizations invest in training programs to ensure employees understand customer expectations and are equipped to handle diverse situations.

Both of the following companies emphasize the importance of investing in their employees’ training to ensure excellent service, which is a key differentiator in their respective industries.

RBC is renowned for its commitment to customer service excellence. The bank offers comprehensive training to its employees through its “Customer First” programs, which are designed to ensure that employees at all levels understand and meet customer needs. They emphasize skills like active listening, problem-solving, and delivering personalized service. RBC has been recognized for its exceptional customer service in the banking industry, contributing to its reputation as a customer-centric financial institution. Additionally, RBC has won various awards for customer satisfaction and service quality over the years.[28]

The Keg is another Canadian company famous for its customer service. Known for its high-quality food and friendly atmosphere, The Keg invests significantly in employee training programs that focus on delivering an exceptional dining experience. Their training includes both technical aspects (such as menu knowledge) and soft skills (like interpersonal communication and empathy), which ensures that employees can connect with guests on a personal level and provide top-notch service. The Keg’s focus on training and employee empowerment has led it to consistently rank highly for customer satisfaction in the restaurant industry.[29]

Scheduling

In manufacturing, managers focus on scheduling the activities needed to transform raw materials into finished goods. In service organizations, they focus on scheduling workers so that they’re available to handle fluctuating customer demand. Restaurants, for example, will have more customers during the peak periods of breakfast, lunch, and dinner, but also during the slower periods in between. If the manager schedules too many people, the labour cost per sales dollar will be too high. If there aren’t enough employees, customers have to wait in line. When that happens, some get discouraged and even leave, and many may never come back.

Scheduling is made easier by information provided by a point-of-sale device built into many cash registers (also known as point-of-sale (POS) machines). For restaurants, the register stores data on every sandwich, beverage, and side order sold by the hour, every hour of the day, every day of the week, and sends that data to a computer system that helps managers set schedules. To determine how many people will be needed for next Thursday’s lunch hour, the manager reviews last Thursday’s data, using sales revenue to determine the appropriate staffing level. Each manager can adjust this forecast to account for other factors, such as current marketing promotions or a local sporting event that will increase customer traffic.

Inventory Control

Businesses that provide both goods and services, such as retail stores and auto-repair shops, have the same inventory control problems as manufacturers: keeping levels too high costs money, while running out of inventory costs sales. Technology, such as the point-of-sale (POS) registers, makes the job easier. POS systems track everything sold during a given time and provide information on how much of each item should be kept in inventory.

For fast-food restaurants, for example, it also makes it possible to count the number of burgers and buns, bags and racks of fries, and boxes of beverage mixes at the beginning or end of each shift. Because there are fixed numbers of supplies—say, beef patties or bags of fries—in each box, employees simply count boxes and multiply. In just a few minutes, the manager knows whether the inventory is correct (and should be able to see if any theft has occurred on the shift).

Operations managers must strike a balance between two threats to productivity: losing production time because they have run out of materials, and wasting money because they are carrying too much inventory. The process of striking this balance is called inventory control, and companies now regularly rely on a variety of inventory-control methods.

Service operations often rely on technology to streamline processes. For example, service organizations may implement customer relationship management (CRM) systems, scheduling software, or automation tools to improve efficiency. Integrating technology helps reduce errors, improve customer interactions, and facilitate communication across departments.

Outsourcing in the Service Sector

Outsourcing is by no means limited to the manufacturing sector. Service providers also outsource many of their non-core functions. Some universities, for instance, outsource functions such as food services, maintenance, bookstore sales, printing, grounds keeping, security, and even residence operations. For example, there are several firms, like RGIS, that offer inventory services. They will send a team to your company to count your inventory for you. As RGIS puts it, “Our teams expertly deliver complete solutions needed to complete a wide variety of retail projects of all sizes, allowing your team to keep customer service as the number one priority.”[30] Some software developers outsource portions of coding as a cost-saving measure. If you’ve ever had to get phone or chat assistance on your laptop, there’s a good chance you spoke with someone in an outsourced call centre. The centre itself may have even been located offshore. This kind of arrangement can present unique challenges in quality control, as differences in accents and the use of slang words can sometimes inhibit understanding. Nevertheless, in this era of globalization, expect the trend towards outsourcing offshore to continue.

3. Quality Control

What if you were late for a test because it took you twenty minutes to get a burger and fries at a drive-through window? Like most people, you’d probably be more or less disgruntled. As a customer, you’re constantly assured that service will be of the highest possible quality, and you tend to avoid brands that have failed to live up to your expectations. When you go to a drive-through window, you expect to be served in a reasonable amount of time. If your expectations are not met, you’ll conclude that you’re the victim of poor quality.

Customer-Centric Approach

Quality in service businesses starts with understanding customer expectations. Service providers like hotels, restaurants, and consultancies focus on exceeding customer satisfaction by continuously improving customer interactions, responsiveness, and personalized service. This includes using customer feedback and measuring satisfaction levels through surveys and reviews.

Employee Training and Empowerment

For service businesses, employees are the core of service delivery. Regular training is essential to ensure employees have the skills and knowledge to meet customer needs and adhere to quality standards. Empowering employees to take initiative and resolve customer issues promptly is a key component of maintaining quality

Total Quality Management (TQM)

Quality in service businesses is managed differently from manufacturing, but the principles of Total Quality Management (TQM) and continuous improvement still apply. The TQM concept involves all employees; when customers wait too long at a drive-through window, it’s the responsibility of a number of employees, not the manager alone.